Method and system for closing type Britten-Rankine combined cycle solar heat power generation

A solar thermal power generation and combined cycle technology, which is applied in solar thermal power generation, mechanical power generation with solar energy, machines/engines, etc., can solve the problems of high system pressure, low condensation temperature, high compression power consumption, and eliminate system pressure. Too high, high efficiency, eliminating the effect of high water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

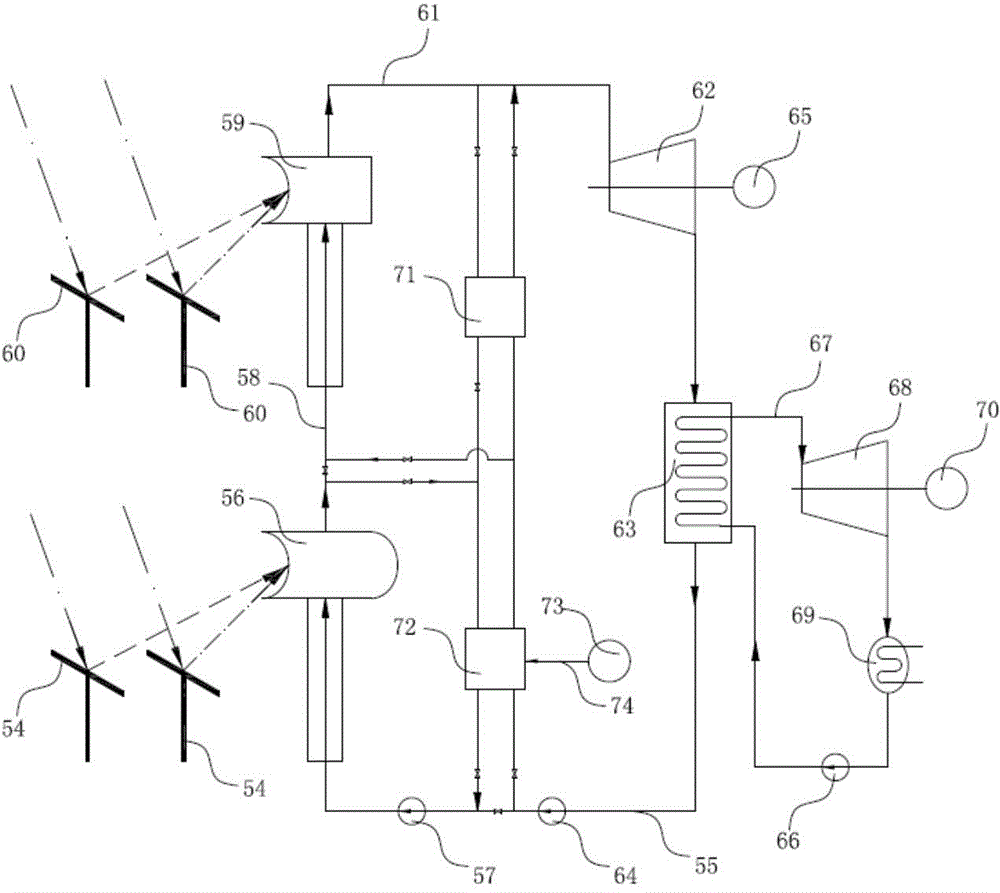

[0081] Such as figure 1 As shown in the present invention, a closed-type Breton-Rankine combined cycle solar thermal power generation method and a schematic flow chart of the system are shown.

[0082] The system includes a closed Bretton cycle and a bottom Rankine cycle; the closed Bretton cycle means that after the condensed water 55 is pressurized by the feed pump 64, it first enters the preheating evaporation heat absorber 56 to absorb heat, Generate saturated or superheated steam 58, and then send it to the cavity receiver 59 of the tower-type solar thermal power generation system to absorb heat, generate high-temperature water vapor 61, and drive the water-gas turbine 62 to drive the water-gas turbine generator 63 to generate electricity, thereby converting solar energy Converted into electric energy; the steam discharged from the water-gas turbine 62 is condensed into condensed water 55 by the condensing evaporator 63, and then sent to the preheating evaporating heat a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com