Super-resolution device and method based on pumping-probe technology

A super-resolution and probe technology, applied in the field of super-resolution, can solve the problems of slow imaging speed, strong optical power, and complex imaging system of STORM microscopy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

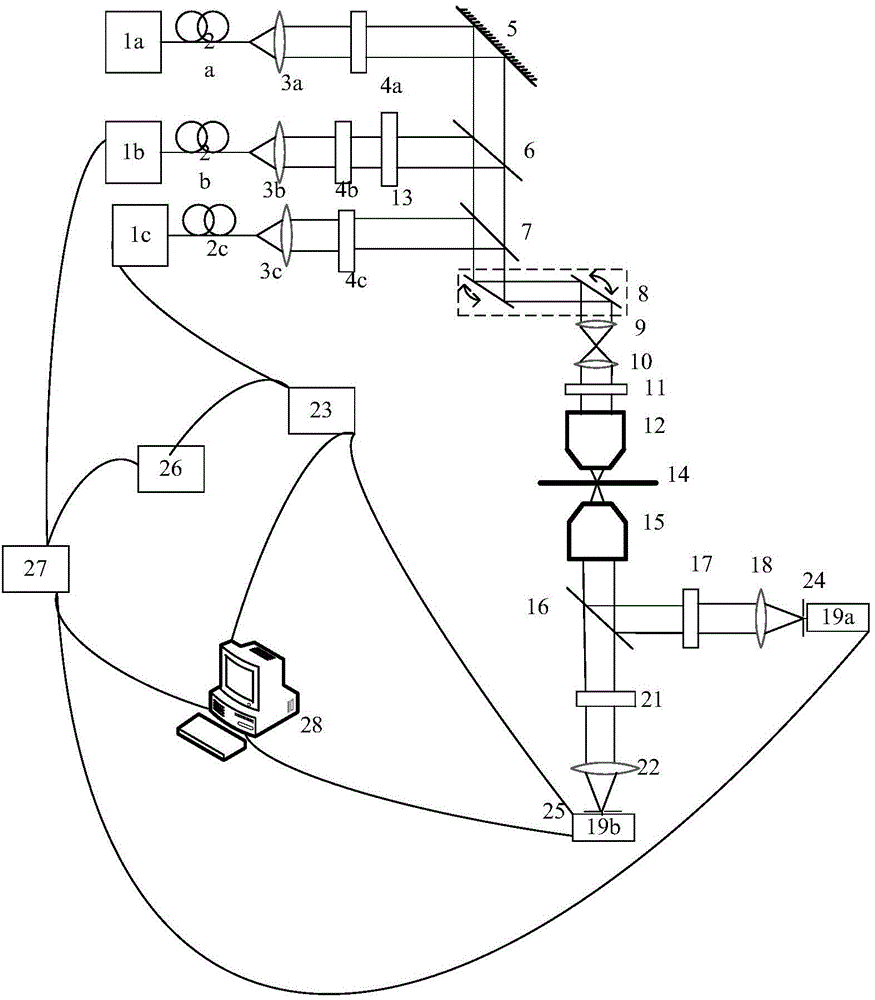

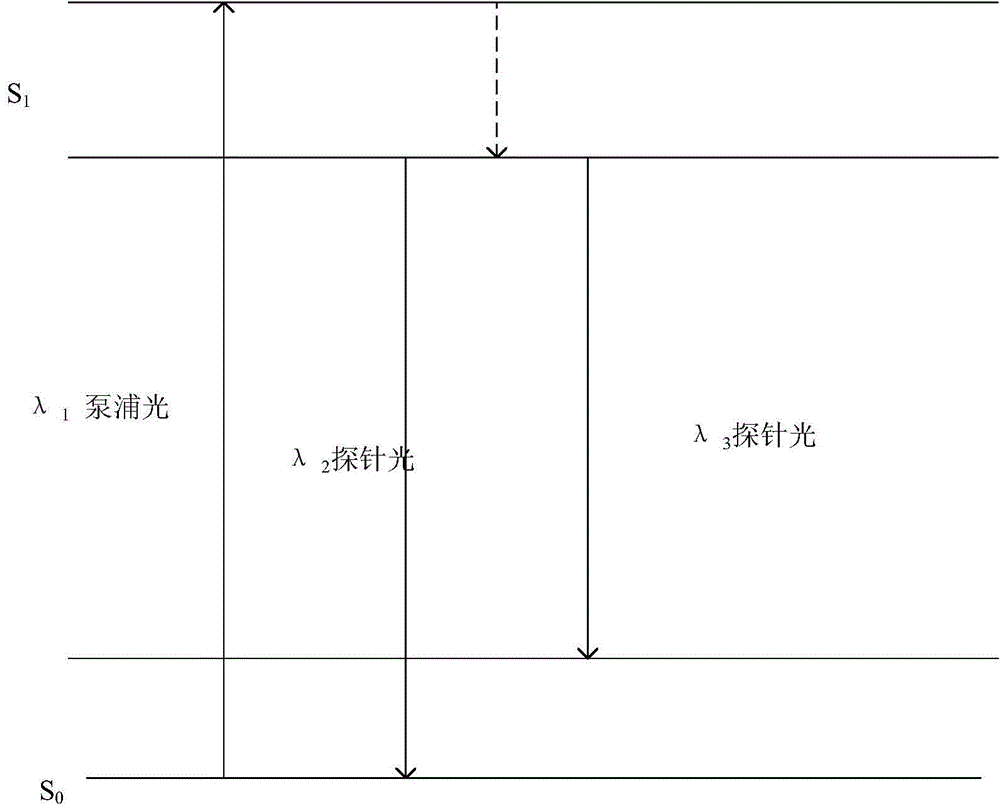

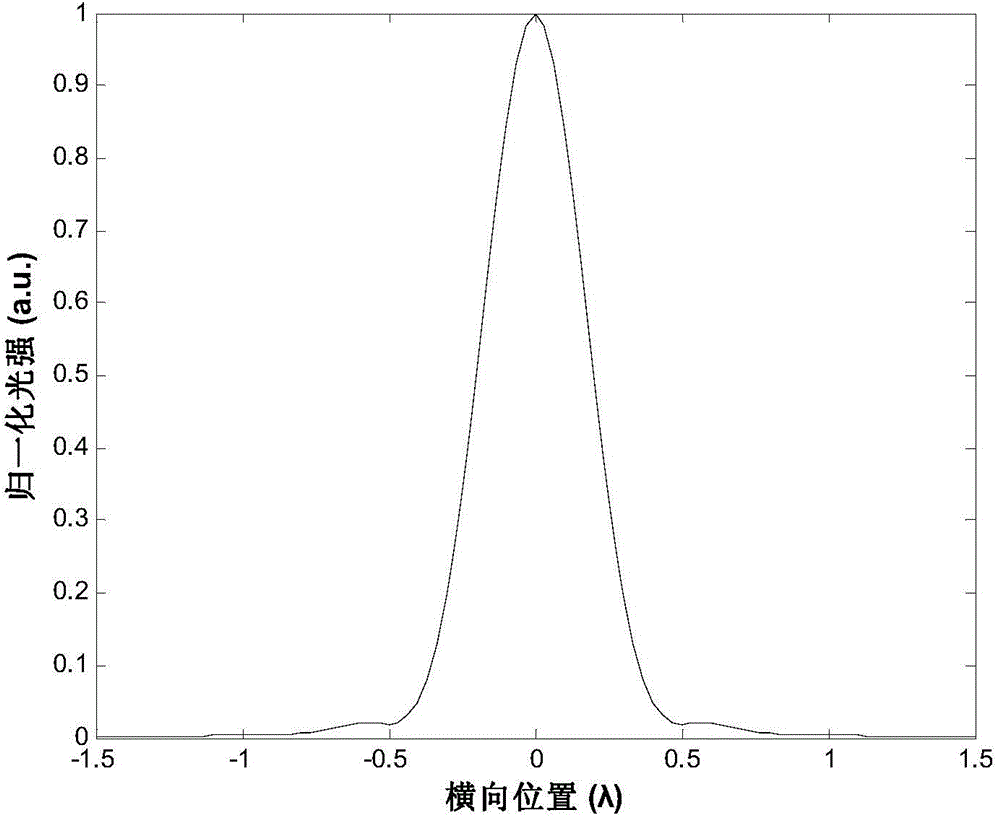

[0059] Such as figure 1 As shown, a super-resolution microscopy device, including: respectively emitting wavelength λ 1 , lambda 2 , lambda 3 Laser 1a, laser 1b and laser 1c, single-mode fiber 2a, single-mode fiber 2b, single-mode fiber 2c, collimator lens 3a, collimator lens 3b, collimator lens 3c, polarizer 4a, polarizer 4b, polarizer Polarizer 4c, reflector 5, dichroic mirror 6, dichroic mirror 7, scanning galvanometer system 8, scanning lens 9, field mirror 10, 1 / 4 wave plate 11, microscopic objective lens 12, microscopic objective lens 15, 0 ~2π vortex phase plate 13 (the vortex phase plate can also be replaced by a spatial light modulator SLM), light-transmitting sample stage 14, dichroic mirror 16, filter 17, filter 21, focusing lens 18, focusing lens 22, pinhole 24, pinhole 25, detector 19a, detector 19b, phase-locked loop 23, phase-locked loop 27, signal generator 26, computer 28.

[0060] Single-mode fiber 2a, single-mode fiber 2b, single-mode fiber 2c, collimato...

Embodiment 2

[0092] When lasers 1b, 1c emit wavelength λ 2 =λ 3 , in order to effectively separate the solid facula and the hollow facula, slightly modify the original device to adopt Figure 6 The device is carried out.

[0093] Such as Figure 6 The super-resolution microscopy device shown includes: respectively emitting wavelength λ 1 , lambda 2 =λ 3 Laser 1a, laser 1b, laser 1c, single-mode fiber 2a, single-mode fiber 2b, single-mode fiber 2c, collimator lens 3a, collimator lens 3b, collimator lens 3c, polarizer 4a, polarizer 4b, polarizer Polarizer 4c, reflecting mirror 5, dichroic mirror 6, scanning galvanometer system 8, scanning lens 9, field mirror 10, 1 / 4 wave plate 11, microscopic objective lens 12, microscopic objective lens 15, 0~2π vortex phase Plate 13 (can be replaced by a spatial light modulator), light-transmitting sample stage 14, optical filter 17, optical filter 21, reflector 29, focusing lens 18, focusing lens 22, pinhole 24, pinhole 25, detector 19a, a detecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com