Planar optical waveguide and manufacturing method thereof

A planar optical waveguide and waveguide core technology, which is applied to optical waveguides, light guides, optics, etc., can solve the problems of increasing instability and process risk, difficulty in controlling birefringence effects, and increasing production costs and risks. Solve the effect of the uniformity of core layer production, solve the accumulation of three image transfer errors, and improve the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] The present invention also provides a method for preparing a planar optical waveguide, comprising the following steps:

[0071] (1) forming a first portion of the isolation layer on the lower cladding layer;

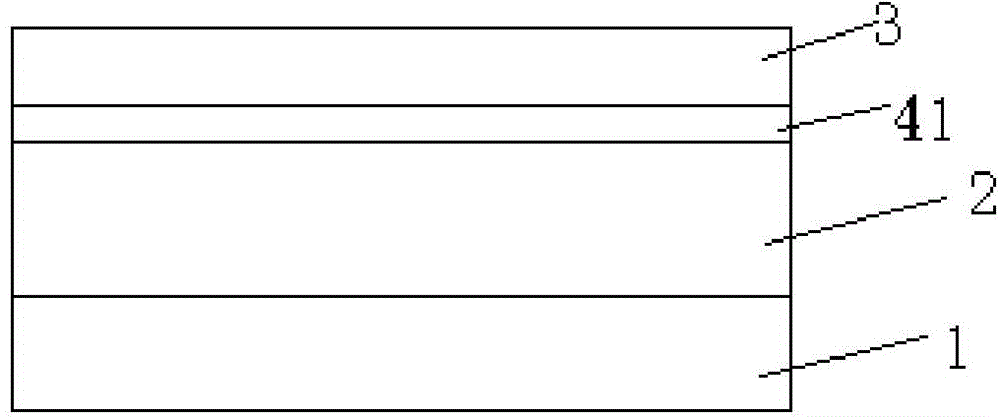

[0072] (2) forming a core layer on the first portion of the isolation layer;

[0073] (3) etching the core layer to form the waveguide core layer with a preset structure;

[0074] (4) forming a second part of the isolation layer on the waveguide core layer and the first part of the isolation layer, the second part of the isolation layer completely fills the gap of the preset structure, and the first part of the isolation layer A part and a second part form the isolation layer and completely cover the waveguide core layer;

[0075] (5) The upper cladding layer is formed on the second portion of the isolation layer.

[0076] In some preferred embodiments, one or any combination of the following conditions may be preferred:

[0077] Described step (3) comprises t...

Embodiment 1

[0090] The preparation method of the planar optical waveguide comprises the following steps:

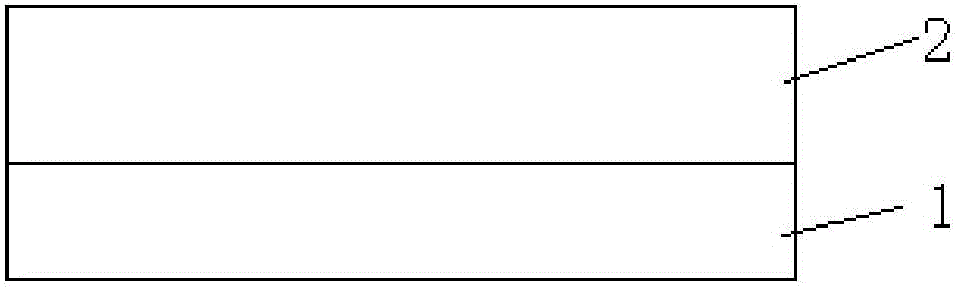

[0091] (1) The lower cladding layer 2 is formed on the substrate 1, the material of the substrate 1 is Si, and the material of the lower cladding layer 2 is SiO 2 ,Such as Figure 1a shown.

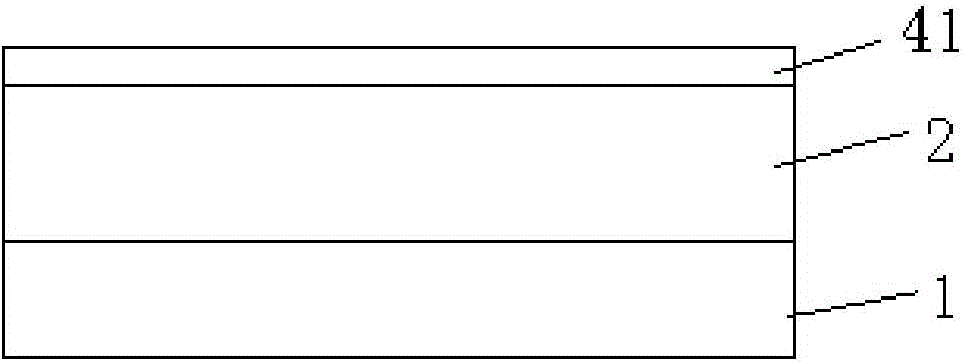

[0092] (2) Using plasma enhanced chemical vapor deposition (Plasma Enhanced Chemical Vapor Deposition, PECVD) process, the growth temperature is 320 ° C, the gas flow ratio: 10% (volume fraction) GeH 4 :C 2 f 6 :SiH 4 :N 2 O is 20:10:17:2000sccm, the RF input power is 700W, and the deposition chamber pressure is 380mTorr, deposit for 10 minutes, and then perform high-temperature annealing to form the first part of the isolation layer 4 with a thickness of 3 μm on the lower cladding layer 2 41. The process conditions for high-temperature annealing treatment are: in an atmosphere of oxygen and inert gas (volume ratio: 1:6), heat up for 100 minutes, keep the temperature at 950°C for 20 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com