A cement enterprise energy information integrated management system

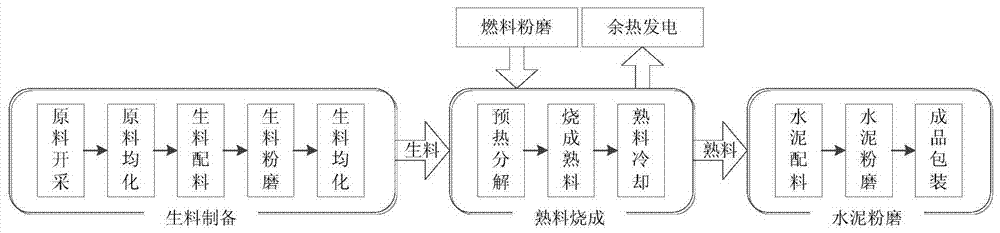

An information integration and management system technology, applied in the field of energy management in the cement production process, can solve the problems of lack of consumption data collection and management, energy waste, lack of energy optimization scheduling, etc., to facilitate product production and energy scheduling management, and reduce development costs. , The effect of transparency of energy usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

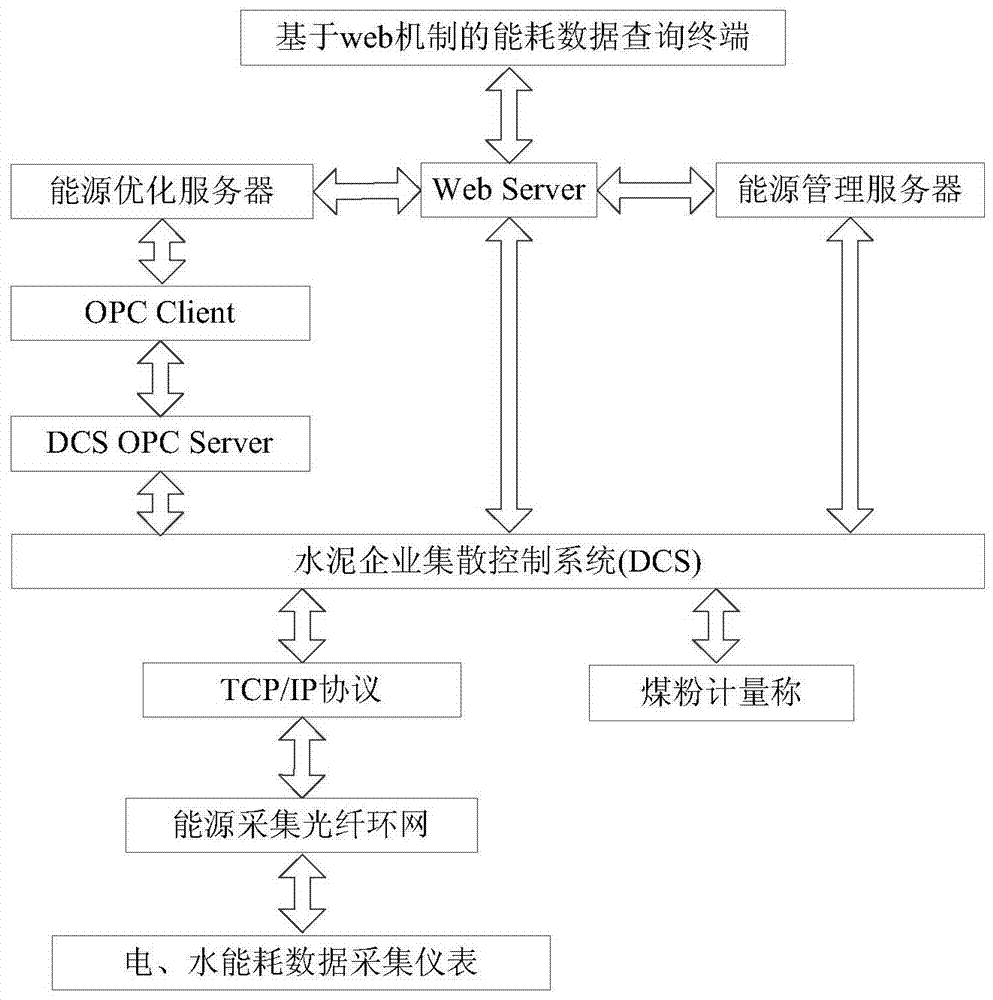

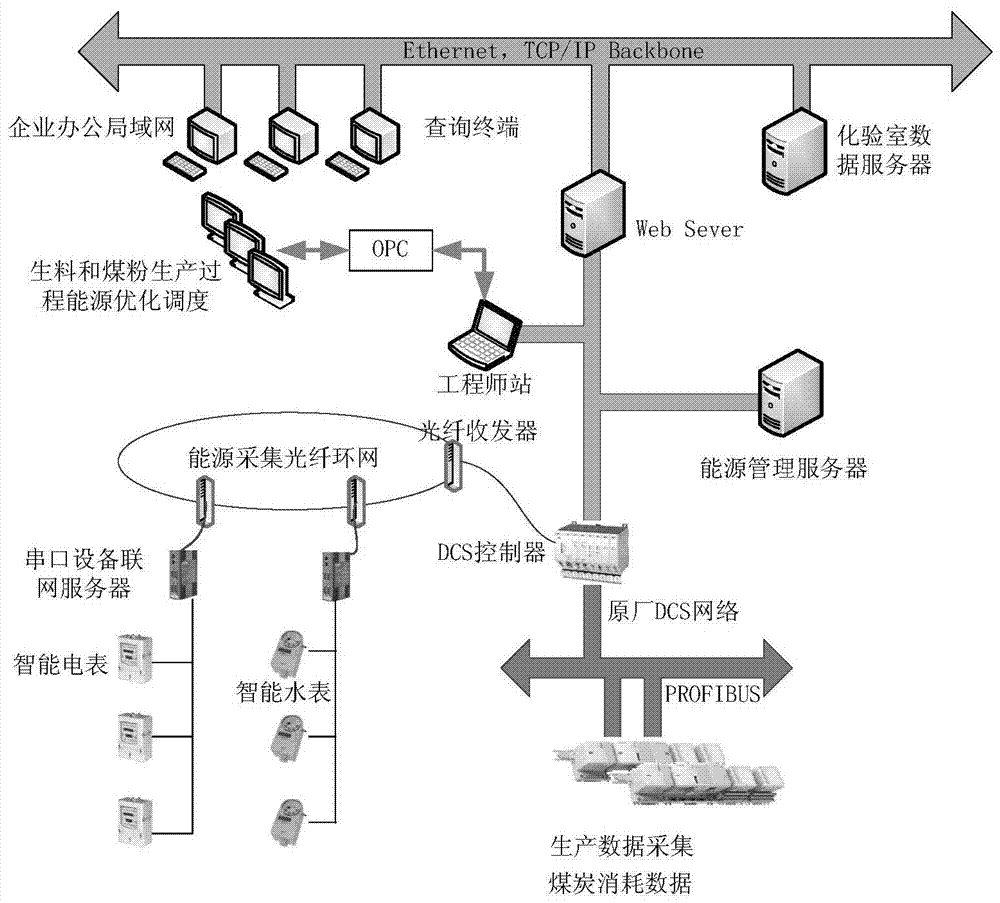

[0074] An energy information integrated management system for cement enterprises in the present invention includes an energy information collection network, an energy management server, an energy optimization server, and a Web Server. The network architecture diagram of the system is shown in the attached image 3 shown. Its hardware mainly includes smart electric meters, smart water meters, serial device networking servers, optical fiber transceivers, cement DCS control systems, energy management center servers, Web Servers, query terminals that support Modbus communication protocol, and software mainly includes energy data analysis and management software, SQL Server2005, OPC Server, OPC Client.

[0075] The energy information collection network includes a smart meter supporting the Modbus communication protocol, a smart water meter, a seri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com