Making method of beef ball

A production method and technology of beef balls, which are applied in the field of beef balls and beef balls production, can solve the problems of single nutrition, etc., and achieve the effect of rich nutrition, full elasticity and strong aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

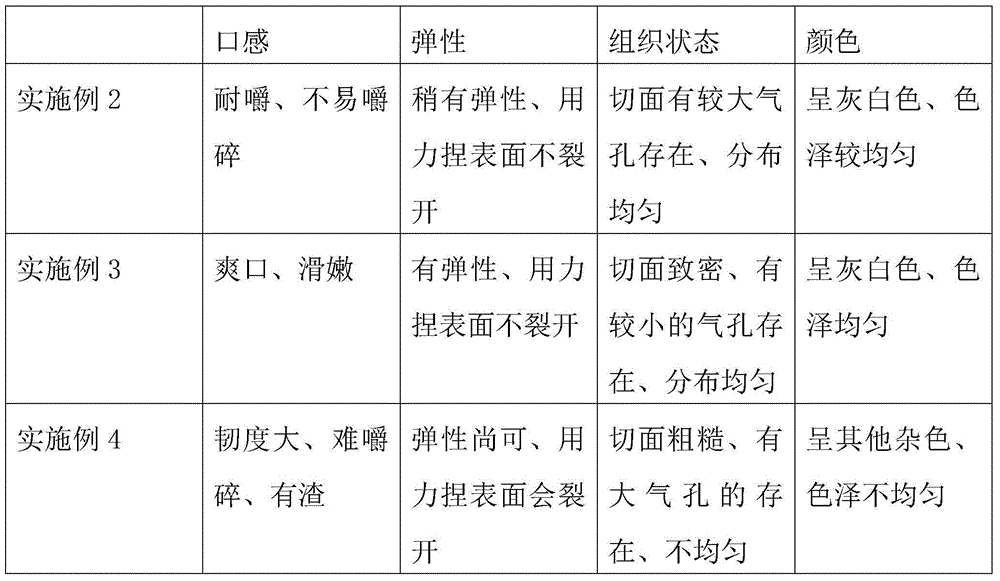

Examples

Embodiment 1

[0021] The preparation method of beef ball provided by the invention, it comprises the steps:

[0022] (1) Trimming of raw materials: remove broken bones, bruised meat, thick fascia and tendon, etc. in the raw beef, and cut the frozen meat into strips;

[0023] (2) Grinding meat: Use a meat grinder to grind the meat strips into minced meat, and then grind them twice to completely grind the meat into minced meat;

[0024] (3) Preparation of leek juice: trim and clean fresh leeks, cut them into long strips, mix them with water and squeeze the juice to obtain leek juice, drain the water and chop into fine pieces;

[0025] (4) Stirring: Pour the minced meat into the chopping machine, chop and mix it into a puree, and then add salt, fat meat, various auxiliary materials, appropriate amount of leek juice, wolfberry, shiitake mushrooms, wolfberry, shiitake mushrooms Chop and mix at high speed to form a thick and fine filling, and finally add starch and mix well;

[0026] (5) Meatba...

Embodiment 2

[0029] In the preparation method of beef balls provided by the present invention, the specific components of the raw and auxiliary materials used for pickling are: 11% of salt, 12% of monosodium glutamate, 12% of starch, 14% of soybean protein, 10.5% of phosphate, 10.1% of carrageenan, edible beef essence 11%, the rest is water.

[0030] Utilize above-mentioned raw material to carry out the step of making beef balls and be:

[0031] (1) Trimming of raw materials: Remove the broken bones, bloody meat, thick fascia and tendons in the raw beef, and cut the frozen meat into small pieces with a length of 3cm, a width of 3cm, and a height of 3cm, weighing about 200g Meat strips;

[0032] (2) Grinding meat: Use a meat grinder to grind the meat strips into minced meat, and then grind them twice to completely grind the meat into minced meat;

[0033] (3) Preparation of leek juice: trim and clean fresh leeks, cut them into strips of 5 mm in length, mix them with water at a ratio of 0....

Embodiment 3

[0038] A method for making beef balls. The specific ingredients of the raw and auxiliary materials used for pickling are: 13% of salt, 13% of monosodium glutamate, 14% of starch, 16% of soybean protein, 11% of phosphate, 10.3% of carrageenan, and 12% of edible beef essence , and the rest is water.

[0039] Utilize above-mentioned raw material to carry out the step of making beef balls and be:

[0040] (1) Trimming of raw materials: Remove broken bones, bloody meat, thick fascia and tendons in the raw beef, and cut the frozen meat into small pieces with a length of 4cm, a width of 4cm, and a height of 4cm, weighing about 250g Meat strips;

[0041] (2) Grinding meat: Use a meat grinder to grind the meat strips into minced meat, and then grind them twice to completely grind the meat into minced meat;

[0042] (3) Preparation of leek juice: trim and clean fresh leeks, cut them into strips of 6 mm in length, mix them with water at a ratio of 0.55 and squeeze the juice to obtain l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com