Preparation methods and application of ganoderma lucidum superfine powder

A technology of Ganoderma lucidum superfine powder and Ganoderma lucidum, which is applied to medical preparations containing active ingredients, pharmaceutical formulas, plant raw materials, etc., can solve the problems of uneven particle size, large particle size range, and high process cost, so as to improve the dissolution rate, Reduce production cost, the effect of particle uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

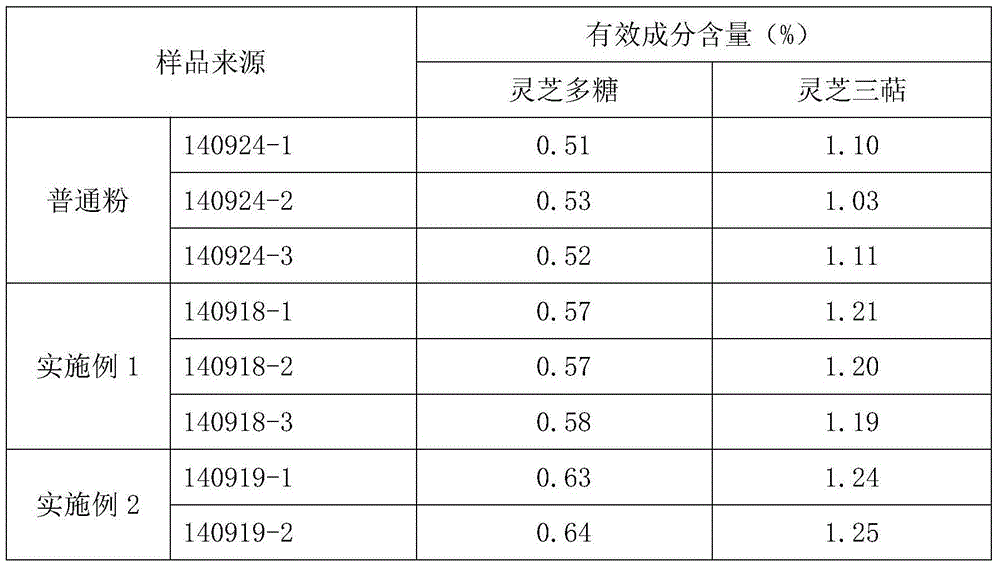

Examples

Embodiment 1

[0034] Embodiment 1 prepares Ganoderma lucidum superfine powder

[0035] The method for preparing Ganoderma lucidum superfine powder in the present embodiment, concrete steps are as follows:

[0036] 1) Use Ganoderma lucidum as raw material, remove impurities, wash with drinking water 3 to 5 times, water pressure 10MPa, slice the cleaned Ganoderma lucidum, and then coarsely grind it to below 80 mesh.

[0037] 2) The ganoderma lucidum powder that has been coarsely powdered is ultrafinely pulverized by a high-energy nano-impact mill, and the grinding medium in the high-energy nano-impact mill tank is continuously impacted and ground for 6 to 10 hours, so that the average particle size of the ultra-fine ganoderma powder reaches 100 ~900nm.

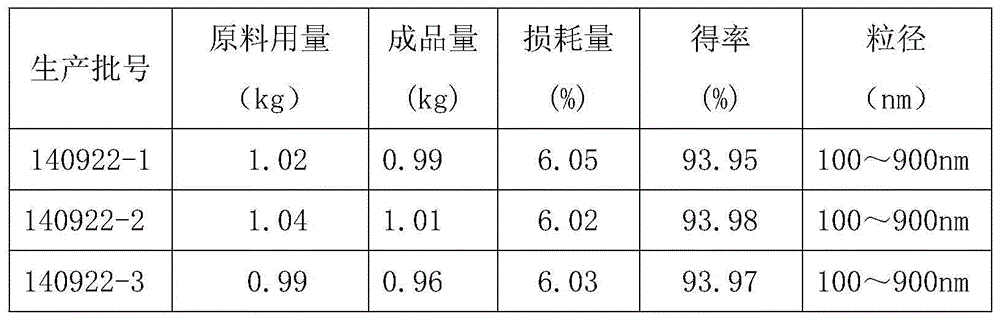

[0038] The production details are shown in Table 1:

[0039] Table 1

[0040] Production batch

[0041] (Remarks: These 3 batches have the same process, but the amount of raw materials is different.)

Embodiment 2

[0042] Embodiment 2 prepares Ganoderma lucidum superfine powder

[0043] The method for preparing Ganoderma lucidum superfine powder in the present embodiment, concrete steps are as follows:

[0044] 1) Raw material processing: take Ganoderma lucidum as raw material, remove the sundries, wash with drinking water 3 to 5 times, water pressure 10MPa, slice Ganoderma lucidum, and put it into the extraction tank;

[0045] 2) Water extraction: add distilled water 5, boil the Ganoderma lucidum in step 1 in an extraction tank and keep boiling for 1 hour, filter to obtain the Ganoderma lucidum water extract and Ganoderma lucidum residue. Add the Ganoderma lucidum residue into distilled water, keep boiling for 30 minutes after boiling, and filter to obtain the Ganoderma lucidum water extract and Ganoderma lucidum residue A;

[0046] 3) Drying of the water extract: combine the Ganoderma lucidum water extracts in step 2), put them in a rotary evaporator, 60 ° C ~ 80 ° C, reduce pressure ...

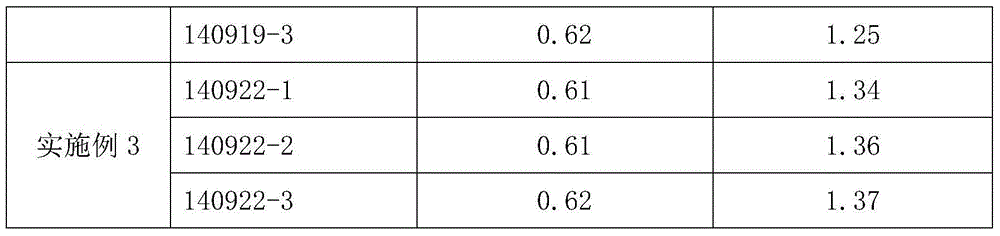

Embodiment 3

[0054] The method for preparing Ganoderma lucidum superfine powder in the present embodiment, concrete steps are as follows:

[0055] 1) Raw material processing: use high-quality, mildew-free Ganoderma lucidum as raw material, remove the sundries, wash with drinking water for 3 to 5 times, water pressure 10MPa, slice the Ganoderma lucidum, and put it into the extraction tank;

[0056] 2) Alcohol extraction: add 50 L of 75% ethanol to the Ganoderma lucidum in step 1, heat to reflux for 45 minutes, and filter to obtain the Ganoderma lucidum alcohol extract and Ganoderma lucidum residue. Add Ganoderma lucidum residue to 25L of 75% ethanol, heat to reflux for 45min, filter to obtain Ganoderma lucidum ethanol extract and Ganoderma lucidum residue A;

[0057] 3) Drying of Ganoderma lucidum ethanol extract: combine the Ganoderma lucidum ethanol extracts in step 2), put them in a rotary evaporator, and conduct rotary evaporation under reduced pressure at 60°C to 80°C to obtain Ganoder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com