A printing and dyeing wastewater treatment process with enhanced internal circulation of muddy water

A technology for printing and dyeing wastewater and treatment process, applied in textile industry wastewater treatment, neutralization water/sewage treatment, water/sewage multi-stage treatment, etc., can solve problems such as high cost, accelerated azo bond cracking, and large sludge volume. , to achieve the effect of promoting degradation, increasing residence time and reducing sludge production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

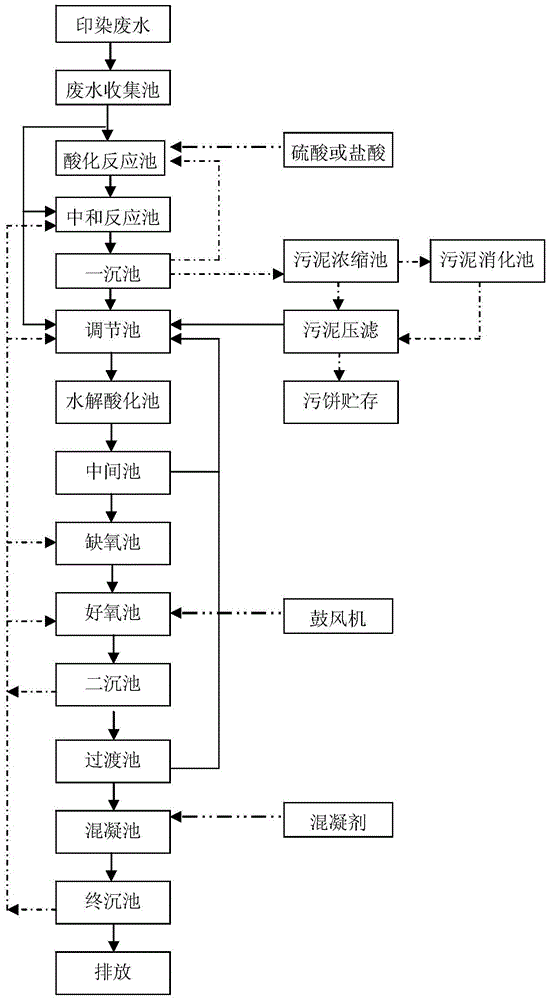

[0039] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

[0040] see figure 1 , the embodiment of the present invention includes the following steps:

[0041] 1) The printing and dyeing wastewater is collected in a wastewater collection tank; the hydraulic retention time of the wastewater collection tank is 0.5-1 h.

[0042] 2) The printing and dyeing wastewater in the wastewater collection pool is divided into three parts:

[0043] The first part of the printing and dyeing wastewater is pumped into the acidification reaction tank, and the pH value of the printing and dyeing wastewater in the acidification reaction tank is adjusted to 2.0-4.5;

[0044] The second part of the printing and dyeing wastewater is pumped into the neutralization reaction tank and mixed with the effluent of the acidification reaction tank, and the pH value of the printing and dyeing wastewater is adjusted to 6.0-8.5;

[0045] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com