Preparation method of plant microfine fibers/rubber powder/polypropylene thermal stretch composite material

A technology of micro-fiber and composite material, applied in the field of hot-stretched composite material and its preparation, can solve the problems of poor weather resistance and dyeability, poor low-temperature impact strength, easy embrittlement, etc., and achieve the effect of good processing performance and mechanical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

[0043] (1) Plant fibers are dried at 95-110°C until the moisture content is below 1%, and crushed into powders with a particle size of 150-200μm;

[0044] (2) The rubber is crushed into a powder with a particle size of 150-200 μm;

[0045] (3) Heat and melt polypropylene and maleic anhydride grafted polypropylene at 170-200°C in a mixer, add fiber powder and rubber powder after complete melting, and mix within this temperature range for 5-10 minutes;

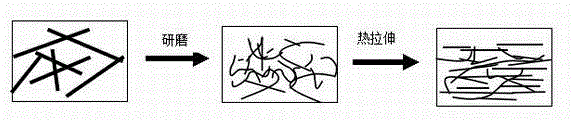

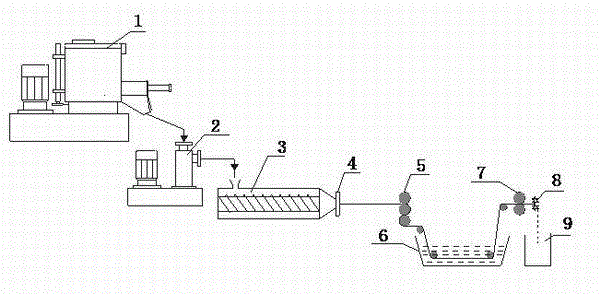

[0046] (4) Put 170-200°C heat transfer oil into the insulation jacket of the high-temperature colloid mill for heat preservation, and transport the mixed polypropylene mixture to the colloid mill for shearing and grinding. The speed of the colloid mill is 3000rpm, and the ground mixture enters the single screw extruder or twin-screw extruder extrusion;

[0047] (5) The extrusion temperature of the extruder is 170-200°C, the die temperature is 190-200°C, the screw speed of the extruder is 20-100rpm, the die is a rect...

Embodiment 1-13

[0050] Table 1 Embodiment 1-13 formula

[0051]

[0052] In order to investigate the mechanical properties of the plant microfiber / rubber powder / polypropylene / heat-stretched composite material prepared by the present invention, the composite material was prepared according to GB / T 2546.2-2003 "Plastic Polypropylene (PP) Molding and Extrusion Materials No. 2" Section: Sample Preparation and Performance Determination "Preparing Samples;

[0053] Tensile strength and elongation at break shall be tested according to the methods specified in GB / T 1040.2-2006 "Determination of Tensile Properties of Plastics Part 2: Test Conditions for Molded and Extruded Plastics";

[0054] The flexural strength and flexural modulus shall be tested according to the method specified in GB / T 9341-2008 "Determination of Flexural Properties of Plastics";

[0055] The notched impact strength is tested according to the method specified in GB / T 1843-2008 "Determination of Izod Impact Strength of Plas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com