Continuous forced drainage and compaction combined soft foundation treatment technical method

A soft foundation treatment and technology technology, applied in the direction of infrastructure engineering, soil protection, construction, etc., can solve the problems that precipitation and dynamic compaction can not be carried out simultaneously, increase the difficulty of construction, increase the workload, etc., and achieve the purpose of shortening precipitation The effect of saving time, reducing workload, and shortening the interval time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

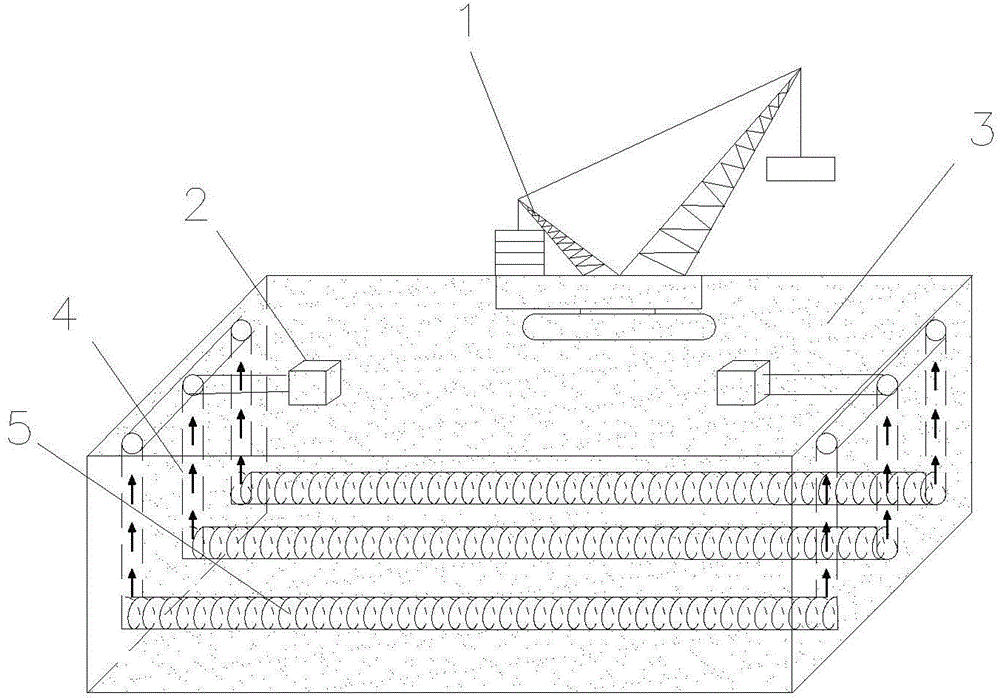

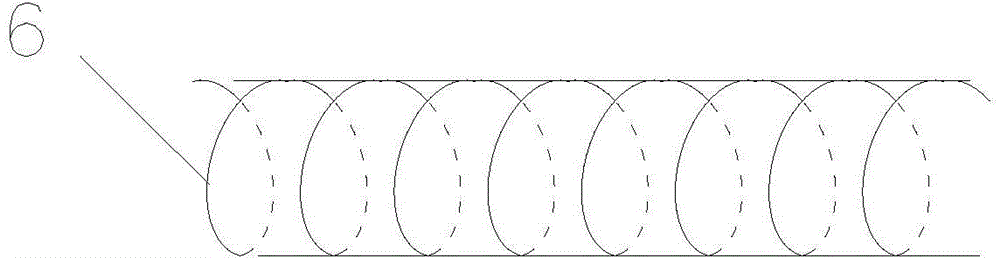

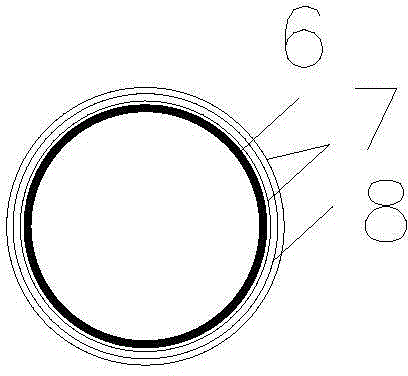

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples to facilitate a clear understanding of the present invention, but they do not limit the present invention.

[0024] Geological surveys should be carried out at the initial stage of project construction to learn more about key soil indicators such as the thickness, water content, particle composition, and permeability coefficient of the dredger fill soil layer, and determine the thickness of the reinforced soil layer, tamping energy, number of tamping times, and spring soft type. Construction parameters such as the depth and spacing of the downpipe arrangement.

[0025] The land area of a certain project is formed by hydraulic dredging. According to the survey report, the dredged fill of this project is mainly composed of silt and silty clay, partially containing thin silt interlayers. The thickness of the soil layer is about 6.2m, the wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com