Boiler tail portion smoke heat energy recovery and low-temperature sulfur removal device and method

A heat energy recovery and heat exchange device technology, applied in preheating, feed water heaters, lighting and heating equipment, etc., can solve the problems of high cost, large investment, unrecoverable and unutilized heat energy, etc., and achieve coal saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

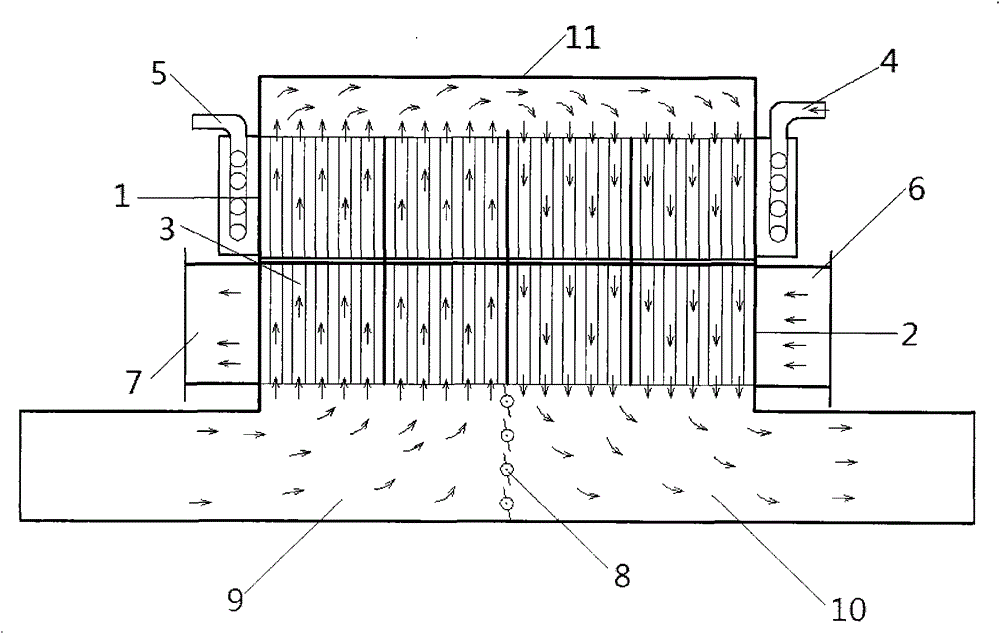

[0022] Such as figure 1 As shown, there is a heat exchanger above the flue. The heat exchanger can be a single-layer air heat exchanger, a single-layer water heat exchanger, or a combination of a single-layer air heat exchanger and a single-layer water heat exchanger. Two-layer or multi-layer structure, the heat exchanger is made of corrosion-resistant high thermal conductivity metal material. In this embodiment, the heat exchanger is a two-layer structure consisting of a single-layer air heat exchanger 2 and a single-layer water heat exchanger 1 . The single-layer water heat exchanger 1 is located above the air heat exchanger 2, and the air heat exchanger is connected with an air inlet pipe 6 and a hot air outlet pipe 7; the water heat exchanger is connected with a low-temperature water inlet pipe 4 and a high-temperature water outlet pipe 5.

[0023] During implementation, the single-layer air heat exchanger or water heat exchanger is composed of multiple heat exchanger uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com