Automatic fuel gas flow control system for wire-drawing and filling-sealing machine

An automatic control system and combustion gas technology, applied in the directions of burners, combustion methods, combustion types, etc., can solve problems such as the inability to guarantee the stability and reliability of the fire, the influence of the qualified rate of product sealing, and the heavy workload of operators. Automatic and precise control of combustion gas flow, improve sealing qualification rate and finished product quality, and avoid the effect of bottle explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

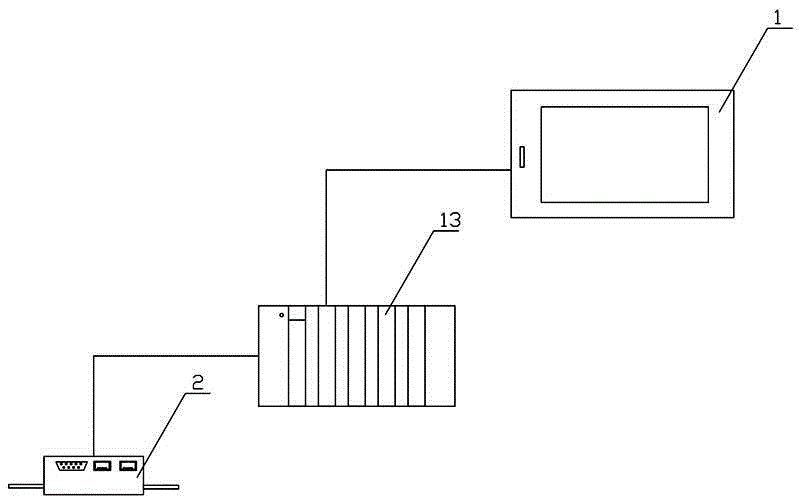

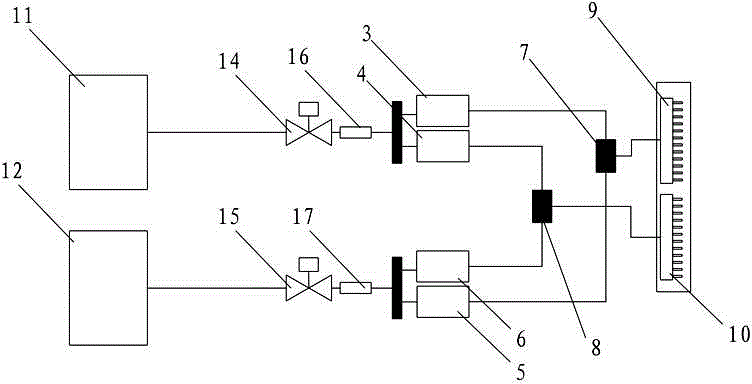

[0024] Such as figure 1 with figure 2 As shown, the combustion gas flow automatic control system for the wire drawing filling and sealing machine of the present invention includes a control assembly 1 and a flow proportional control valve assembly 2, and the input ends of the flow proportional control valve assembly 2 are respectively connected to the assisted gas source (such as: oxygen The gas source 11) and the gas source 12 are connected, the output end of the flow proportional control valve assembly 2 is connected with the burner assembly, the control end of the flow proportional control valve assembly 2 is connected with the control assembly 1 and receives the control signal of the control assembly 1 To adjust the mixing ratio and / or flow of combustion gas.

[0025] In a specific application example, the control component 1 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com