Biomass gasification stove

A biomass and gasification furnace technology, applied in the field of cookers, can solve the problems of short service life of gasification stoves, low calorific value of gas production, incomplete gasification, etc., and achieves short heating startup time, high gasification reaction temperature, and high The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention and its beneficial technical effects will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

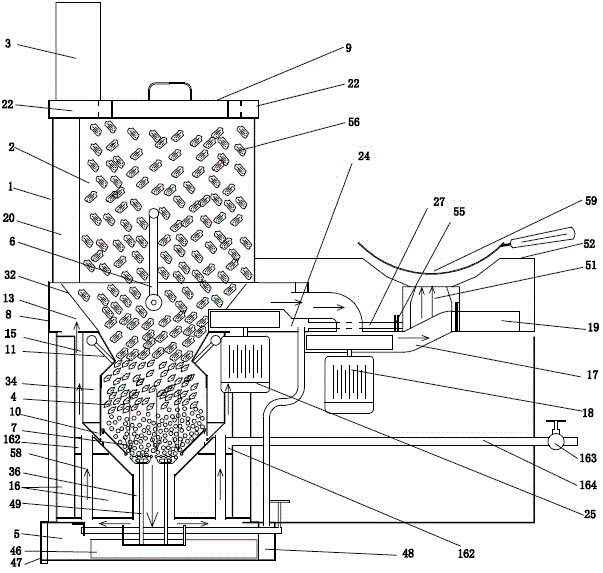

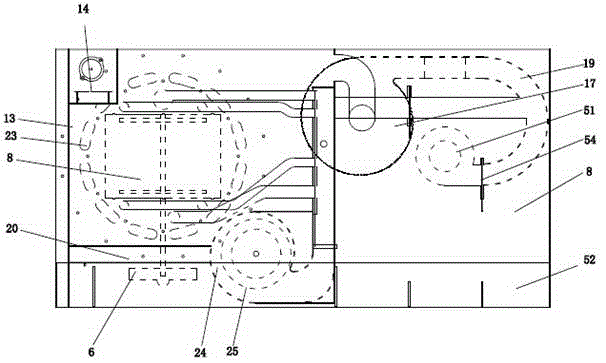

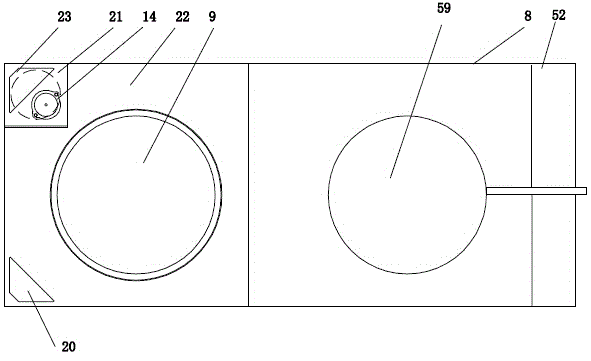

[0028] see figure 1 ~ Figure 6 , The biomass gasification stove includes a furnace body 1, and a fuel bin 2, a middle connecting block 8, a gasification furnace core 4, and an ash chamber 5 arranged on the furnace body 1 from top to bottom; a water tank 16 is arranged on the periphery of the furnace core The middle connection block 8 is provided with a smoke exhaust valve 14 connected to the gasification furnace core 4; a smoke exhaust channel 23 and a wind pressure transmission channel 20 are provided next to the fuel bin 2; It is a smoke exhaust chamber 21 and a hopper mouth pressurization chamber 22, the hopper mouth booster chamber 22 is connected with the wind pressure transmission channel 20, and the smoke exhaust passage 23 is connected with the smoke exhaust valve 14 and the smoke exhau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com