Electronic liquid densimeter

A density meter and liquid technology, applied in the field of measurement, can solve the problems of the Baume hydrometer being fragile, the measurement error is large, and the inability to perform remote transmission, etc., and achieve the effects of easy popularization, simple structure and simple principle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The description will be further described below in conjunction with the accompanying drawings and specific embodiments.

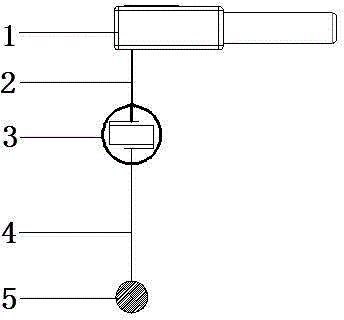

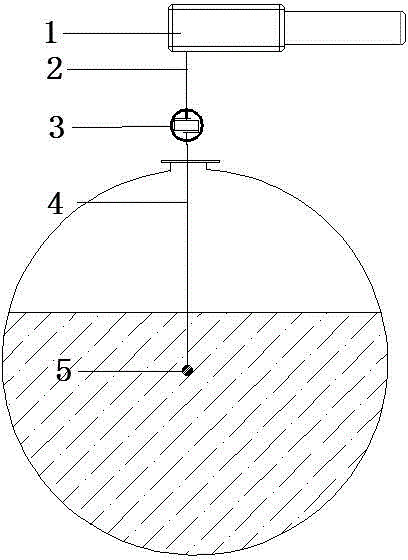

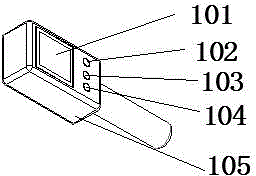

[0019] combine figure 1 , figure 2 , image 3 , Figure 4 The liquid electronic density meter of the present embodiment is composed of a density display instrument 1, a signal transmission cable 2, a balance box 3, a measuring wire 4, and a measuring probe 5. The above-mentioned density display instrument 1 includes a liquid crystal display 101, a power switch 102, a clear Zero button 103, hold button 104, explosion-proof housing 105, the above-mentioned balance box 3 includes a load cell fixing frame 301, a high-precision load cell 302, and a balance box shell 303, and the above-mentioned measuring probe is made of low-expansion quartz glass or alloy .

[0020] Density indicator 1 is an explosion-proof shell with a battery inside, turn on the power switch 102, the display screen 101 lights up, and the current density is displayed as 0 before ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com