Hydride generation and sample introduction method of germanium

A hydride generation and element technology, applied in the field of atomic spectroscopic analysis, can solve the problems that affect the determination of germanium, difficult to carry concentrated acid, and high potential danger, achieve the best promotion and application value, save reagent consumption, and reduce human injury. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

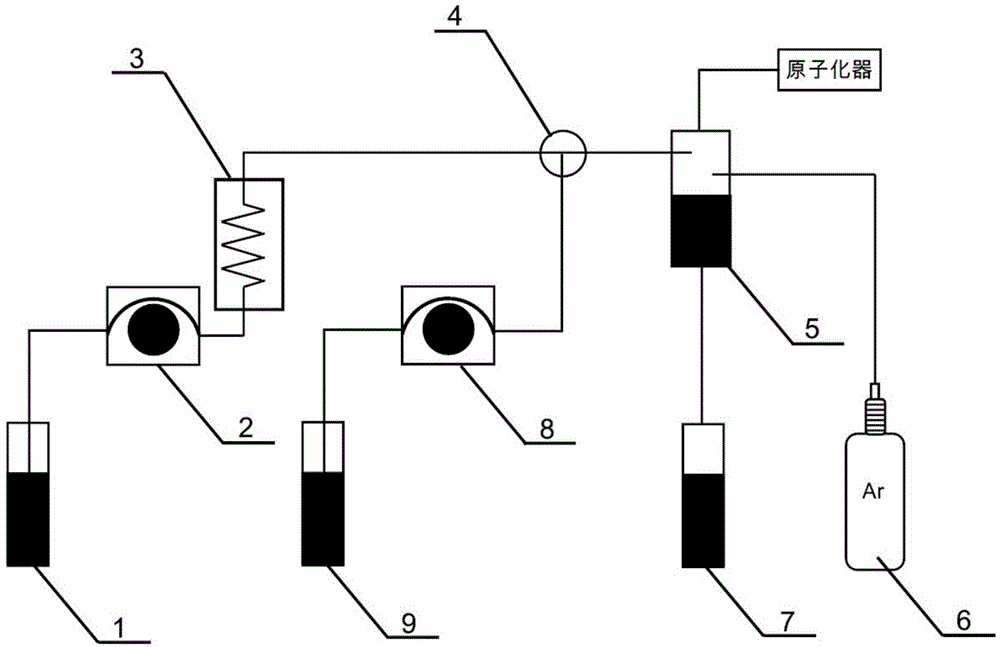

[0029] figure 1 It is a schematic structural diagram of a germanium hydride generation sampling device according to an embodiment of the present invention; as shown in the figure, the device includes: 1-sample solution to be tested; 2-the first peristaltic pump; 3-sample storage ring; 4- Three-way mixing module; 5-gas-liquid separator; 6-argon gas source; 7-waste liquid cup; 8-second peristaltic pump; 9-potassium borohydride solution.

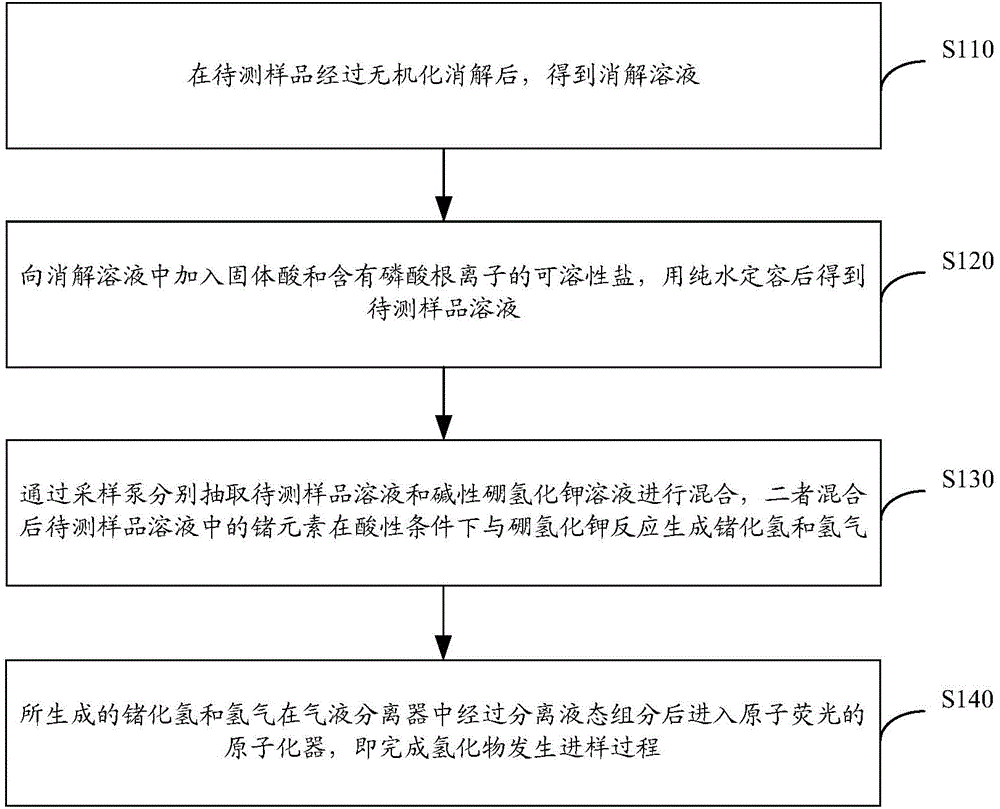

[0030] figure 2 It i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com