X-ray detection system for PCB production

A technology of PCB board and detection system, applied in the field of X-ray detection system, can solve problems such as signal instability and blurring, and achieve the effects of simple and convenient operation, improved quality, and stable and reliable imaging information.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

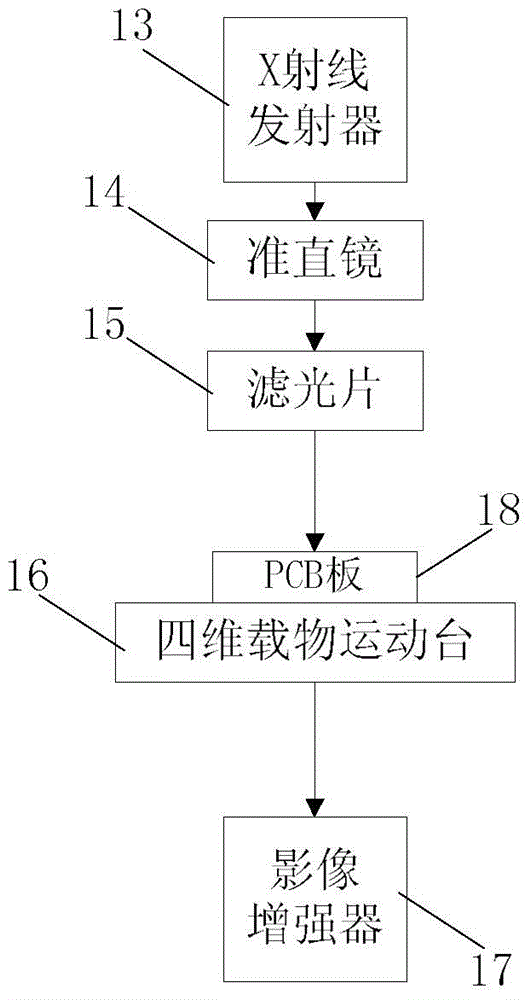

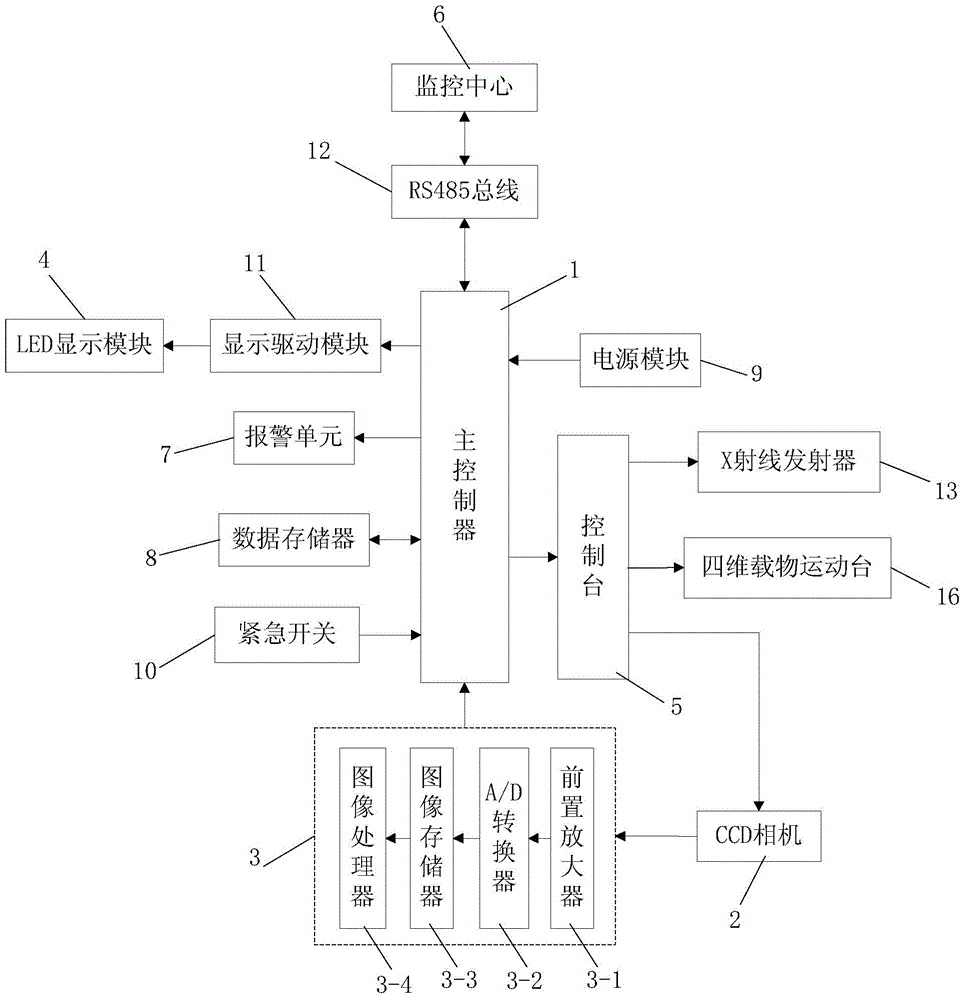

[0027] like figure 1 , figure 2 As shown, the present invention includes an X-ray detection module, a CCD camera 2, an image preprocessing module 3 for amplifying and enhancing the image information collected by the CCD camera 2, and an image preprocessing module 3 for processing and processing the collected image information The X-ray detection module, the CCD camera 2 and the main controller 1 controlled by the four-dimensional object moving table, the X-ray detection module includes X-ray emitters 13 arranged in turn on the transmission optical path of X-rays, used to limit X-rays A collimating mirror 14 in the optical path range, a filter 15 for filtering out light impurities, a four-dimensional object-carrying table 16 for placing a PCB board 18, and an image intensifier 17 for receiving and strengthening images, the CCD camera 2 is arranged at the output window place of image intensifier 17, and described CCD camera 2 joins with the input end of image preprocessing mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com