Dispersion solution of graphene nanosheet and preparation method of dispersion solution

A graphene nanosheet and dispersion technology, applied in the field of nanomaterials, can solve problems such as low efficiency and complicated process, and achieve the effects of low cost, simple and easy preparation method, and easy mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

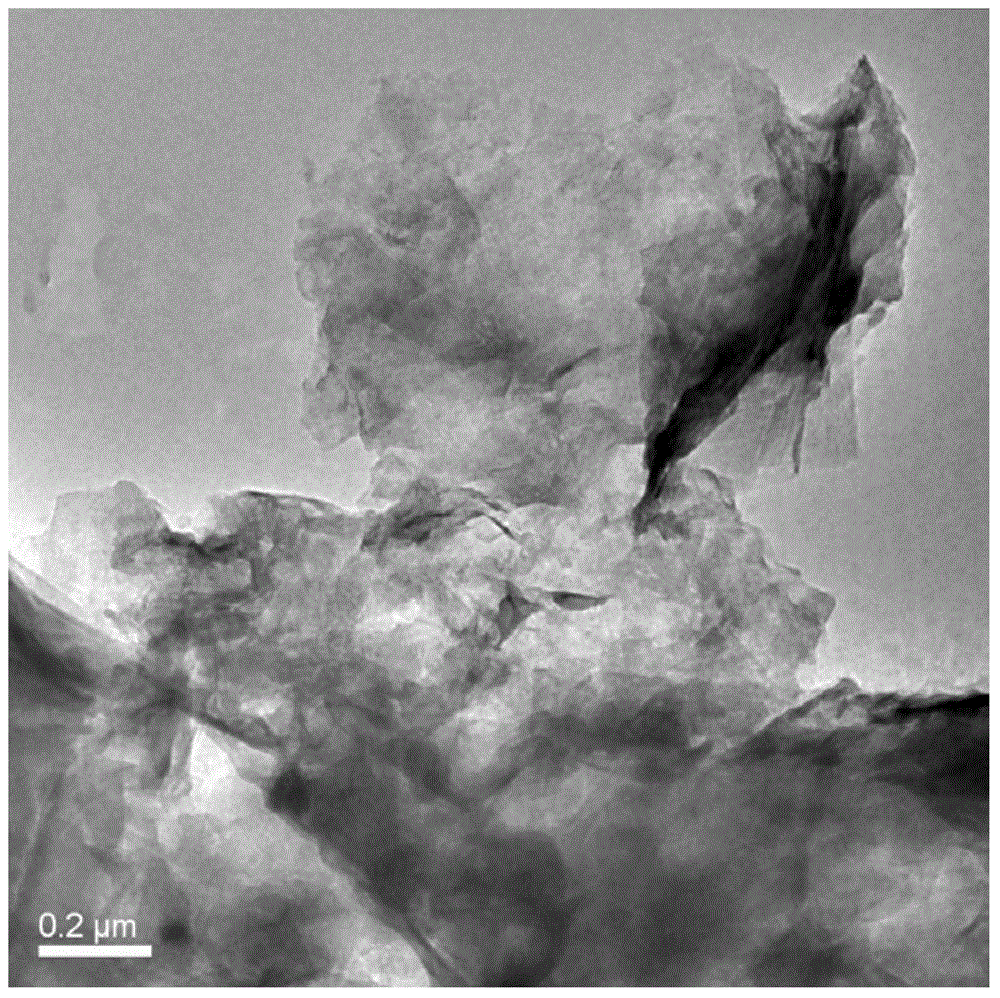

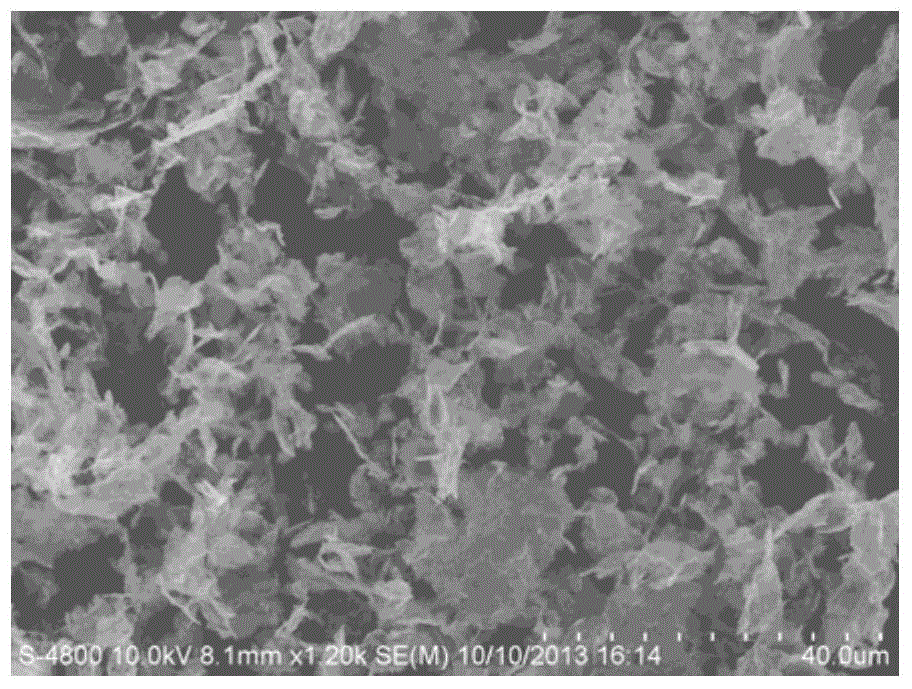

[0033] The starch and solid graphite were mixed at a mass ratio of 139:1, and the mixture was added to a grinder for mechanical grinding. The grinding rotation number is 300r.p.m, and the grinding time is 24h, and a single-layer or several-layer graphene nanosheet material with a thickness of 0.35nm-7nm dispersed in the starch is obtained. 1 g of starch-graphene nanosheets was dissolved in 50 g of dimethyl sulfoxide DMSO, and the above solution was separated by centrifugation for 5 times to obtain a dispersion of graphene in DMSO.

Embodiment 2

[0035] Chitin and solid graphite are mixed at a ratio of 19:1, and the mixture is added to a grinder for solid-state mechanical grinding. The grinding rotation number is 200r.p.m, and the grinding time is 48h respectively, and the single-layer or several-layer graphene nanosheet material with a thickness of 0.35nm-7nm dispersed in chitin is obtained. Dissolving 1 g of chitin-graphene nanosheets in 50 g of hydrochloric acid solution, and centrifuging the dissolved chitin solution five times to obtain a dispersion of graphene in hydrochloric acid.

Embodiment 3

[0037] Same as Example 2, except that chitin is replaced by one of natural woody cellulose or natural herbal cellulose.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com