Method for treating organic wastewater by using sodium bismuthate and plasma

A plasma and organic wastewater technology, applied in the field of wastewater treatment, can solve the problems of limited deep mineralization capacity and high dosage of sodium bismuthate, and achieve the effects of short reaction time, simple operation and improved removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

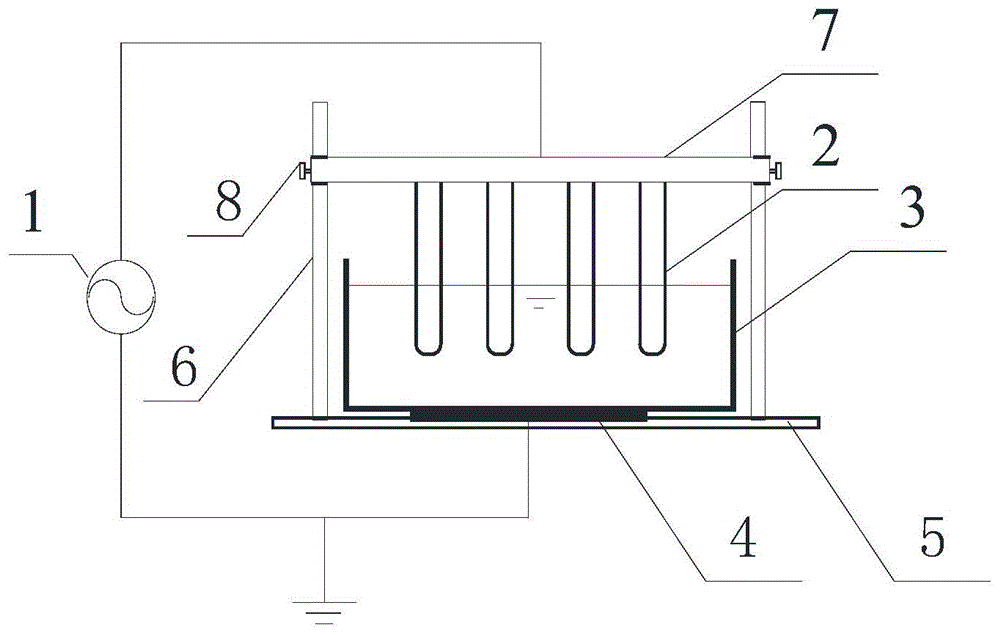

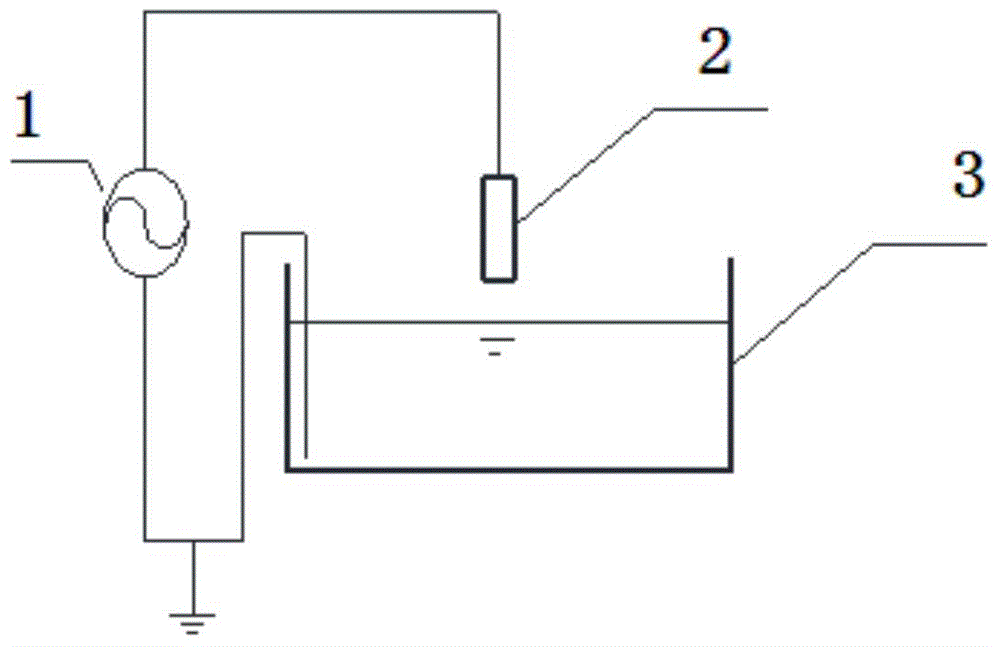

[0027] Prepare 100mg / L aniline simulated wastewater with a pH value of 6.5. Weigh 0.2g NaBiO 3 2H 2 O was added to 250mL solution, stirred evenly, and placed in a dark place for 30min figure 1 In the dielectric barrier discharge device shown. The output voltage of the AC power supply is adjusted to 20kV, the discharge frequency is 17Hz, the high-voltage electrode is in contact with the liquid surface, and the reaction is carried out at room temperature and pressure for 10 minutes. The results show that the removal rate of aniline in wastewater can reach 62.81%, and the removal rate of TOC is 45.12%. Under the same experimental conditions, the removal rate of simulated aniline wastewater treated by dielectric barrier discharge alone was 42.16%, and the removal rate of TOC was 29%. Add 0.2g NaBiO separately 3 2H 2 The removal rate of O was 5.11% for aniline and 0.9% for TOC under sunlight for 10 minutes.

Embodiment 2

[0029] Prepare 100mg / L aniline simulated wastewater with a pH value of 6.5. Take 250mL simulated wastewater, adjust the pH to 10 with 0.1mol / L NaOH, weigh 0.2g NaBiO 3 2H 2 Add O into the solution, stir evenly, and put it in the dark place for 30 minutes figure 1 In the dielectric barrier discharge device shown. The output voltage of the AC power supply is adjusted to 20kV, the discharge frequency is 17Hz, the high-voltage electrode is in contact with the liquid surface, and the reaction is carried out at room temperature and pressure for 10 minutes. The results showed that the removal rate of aniline in wastewater was 44.39%, and the removal rate of TOC was 28.64%. Under the same experimental conditions, the removal rate of simulated aniline wastewater treated by dielectric barrier discharge alone was 29.76%, and the removal rate of TOC was 12.34%. Add 0.2g NaBiO separately 3 2H 2 The removal rate of O was 3.06% for aniline and 0.07% for TOC under fluorescent light for ...

Embodiment 3

[0031] Prepare 25mg / L aniline simulated wastewater with a pH value of 6.5. Weigh 0.05g NaBiO 3 2H 2 O was added to 250mL solution, stirred evenly, and placed in a dark place for 30min figure 1 In the dielectric barrier discharge device shown. The output voltage of the AC power supply is adjusted to 18kV, the discharge frequency is 17Hz, the high-voltage electrode is in contact with the liquid surface, and the reaction is carried out at normal temperature and pressure for 10 minutes. The results show that the removal rate of aniline in aniline wastewater can reach 91.24%, and the removal rate of TOC is 54.87%. Under the same experimental conditions, the removal rate of simulated aniline wastewater treated by dielectric barrier discharge alone was 80.22%, and the removal rate of TOC was 6.29%. Add 0.05g NaBiO3·2H separately 2 The removal rate of O and aniline was 10.35% and TOC removal rate was 2.17% under fluorescent light for 10 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com