Internal gelation method for preparation of ceramic microspheres with glue solution stable at room temperature

A technology for ceramic microspheres and glue solution, which is applied in the field of internal gelation for preparing ceramic microspheres, can solve the problems that the inner gelation process needs to be deepened, the glue solution is unstable, and the large-scale application of the inner gelation process is restricted, and the realization of Mass production, uniform size, good sphericity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

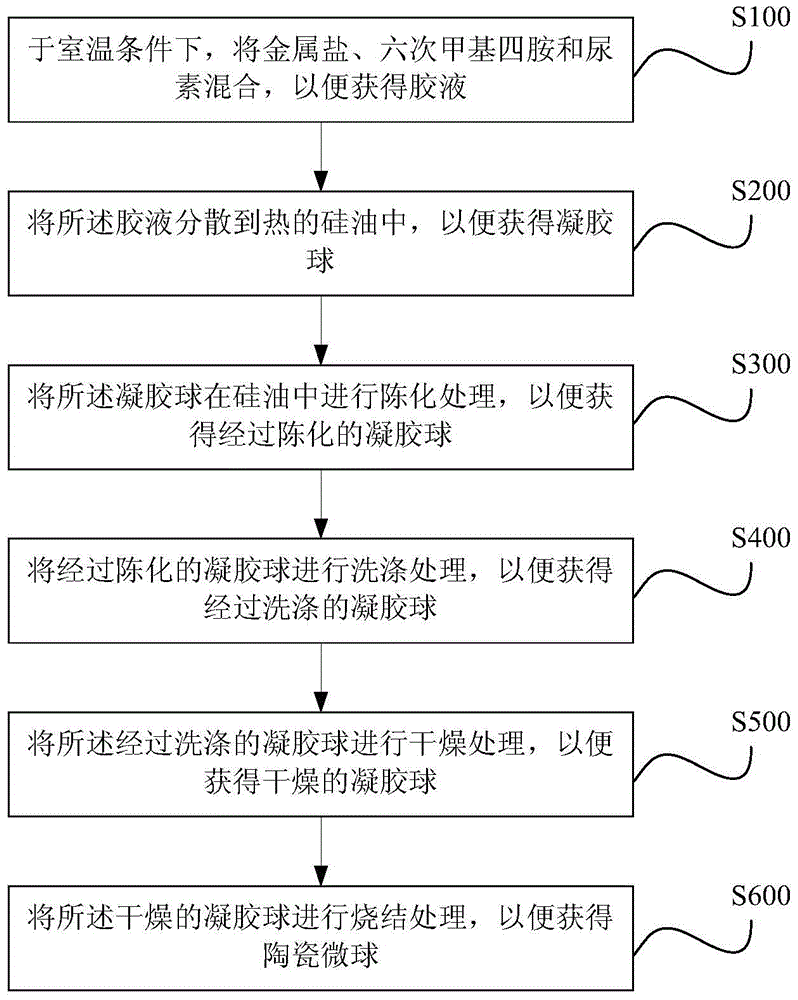

Method used

Image

Examples

Embodiment 1

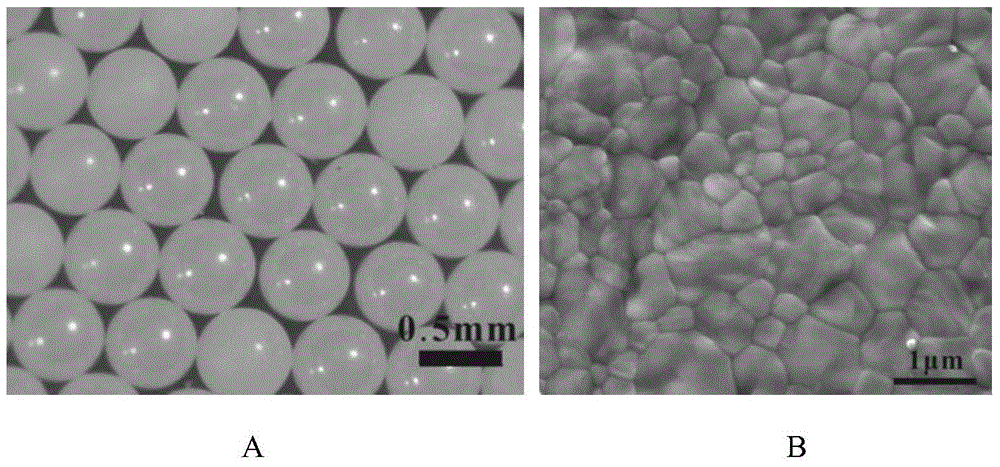

[0070]ZrO 2 Preparation of ceramic microspheres:

[0071] (1) Prepare a mixed solution containing 3mol / L hexamethylenetetramine (HMTA) and 0.7mol / L urea (Urea) at room temperature;

[0072] (2) Configuration containing 1.6mol / L of ZrO(NO 3 ) 2 and 0.14mol / L of Y(NO 3 ) 3 The mixed solution, and concentrated nitric acid is added to the mixed solution to make the final hydrogen ion concentration be 1.35mol / L;

[0073] (3) The above two solutions were left to stand at room temperature for 1h, then the solution containing HMTA and Urea was added to the solution containing Zr and Y, and fully mixed; the prepared glue solution was stored at room temperature for 1h before use Dispersed in gelling. The concentration of metal ions in the final glue is about 0.8-1.1mol / L, the molar ratio of HMTA to metal ions is 1.1-1.3, the molar ratio of urea to metal ions is 0.3-0.65, and the pH value is between 1-2. between;

[0074] (4) Disperse the glue solution into the silicone oil at 85...

Embodiment 2

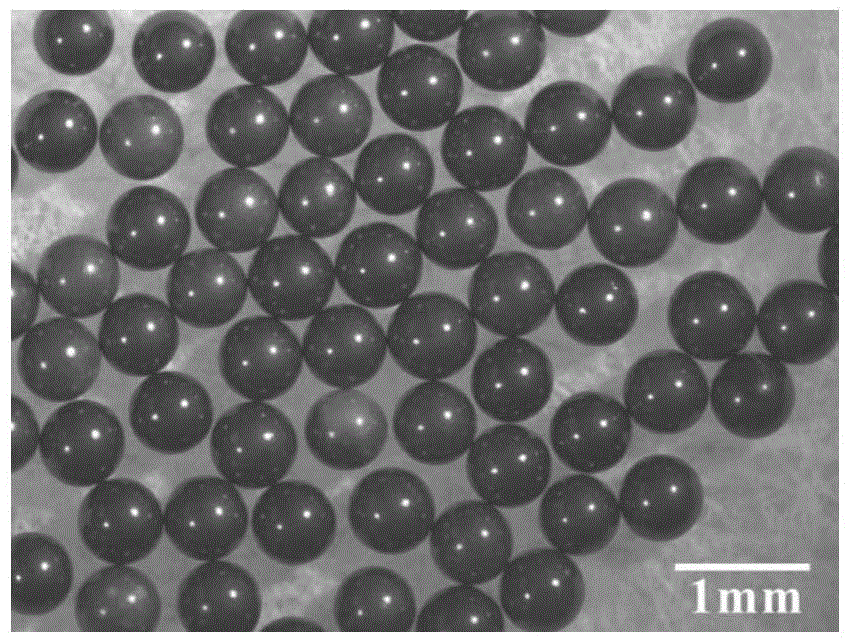

[0081] ZrC-ZrO 2 Preparation of composite ceramic microspheres

[0082] (1) Prepare a mixed solution containing 3mol / L hexamethylenetetramine (HMTA) and 0.7mol / L urea (Urea) at room temperature,

[0083] (2) Configuration containing 1.6mol / L of ZrO(NO 3 ) 2 and 0.14mol / L of Y(NO 3 ) 3 The mixed solution, and concentrated nitric acid is added to the mixed solution to make the final hydrogen ion concentration be 1.35mol / L;

[0084] (3) The above two solutions were left to stand at room temperature for 0.5-1 h, then the solution containing HMTA and Urea was added to the solution containing Zr and Y, and mixed well. Add carbon powder to the above mixture and add Triton X-100 to make the dispersion of carbon powder in the mixture uniform and stable. The prepared glue solution was stored at room temperature for 0.5-1 hour, and then ultrasonically dispersed for 5 minutes for gelation and dispersion. The concentration of metal ions in the final glue solution is about 0.8-1.1mol...

Embodiment 3

[0092] al 2 o 3 Preparation of Ceramic Microspheres

[0093] (1) Prepare a mixed solution containing 3.2mol / L hexamethylenetetramine (HMTA) and 1mol / L urea (Urea) at room temperature;

[0094] (2) Configuration containing 1.6mol / L Al(NO 3 ) 3 solution, and add an appropriate amount of concentrated ammonia water to the mixed solution to make the pH of the mixed solution 1.5 to 2.5;

[0095] (3) Put the above two solutions at room temperature for 1h, then add the solution containing HMTA and Urea to the solution containing Al, and mix well; the prepared glue solution is stored at room temperature for 1h and then used for glue Coagulation dispersed. The concentration of metal ions in the final glue solution is about 0.8-1.1mol / L, the molar ratio of HMTA to metal ions is 1.5-2, the molar ratio of urea to metal ions is 0.3-0.65, and the pH value is between 4-5. between;

[0096] (4) Disperse the glue solution into the silicone oil at 85-90°C using the bench of the internal g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com