A kind of continuous production process of hexafluoropropylene oxide

A hexafluoropropylene oxide and production process technology, applied in the field of continuous production process of hexafluoropropylene oxide, can solve the problems of poor mixing effect, complex process and high energy consumption in tubular reactors, and achieve precise control of reaction conditions and process Simple process and good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

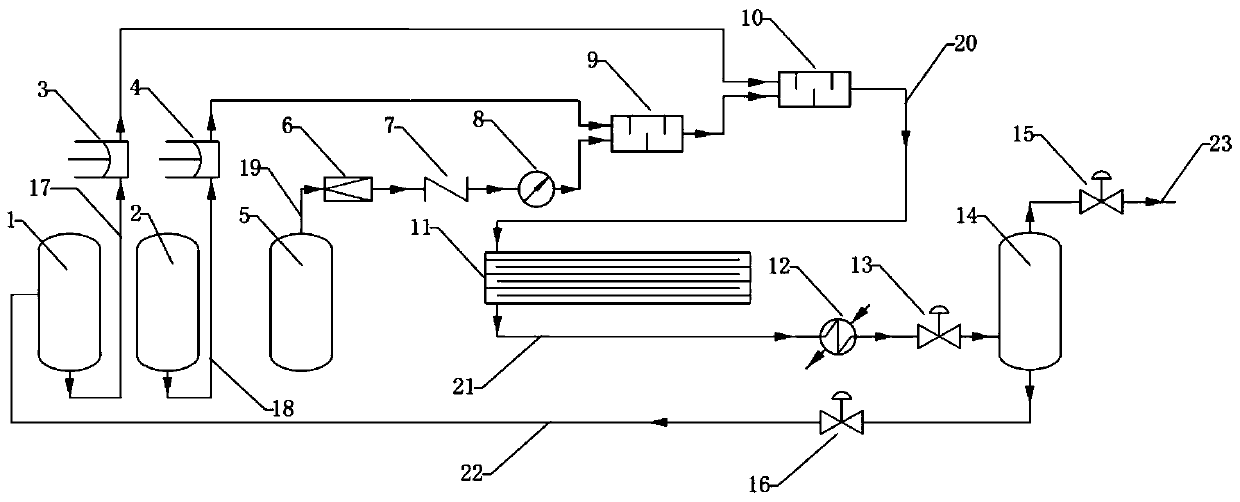

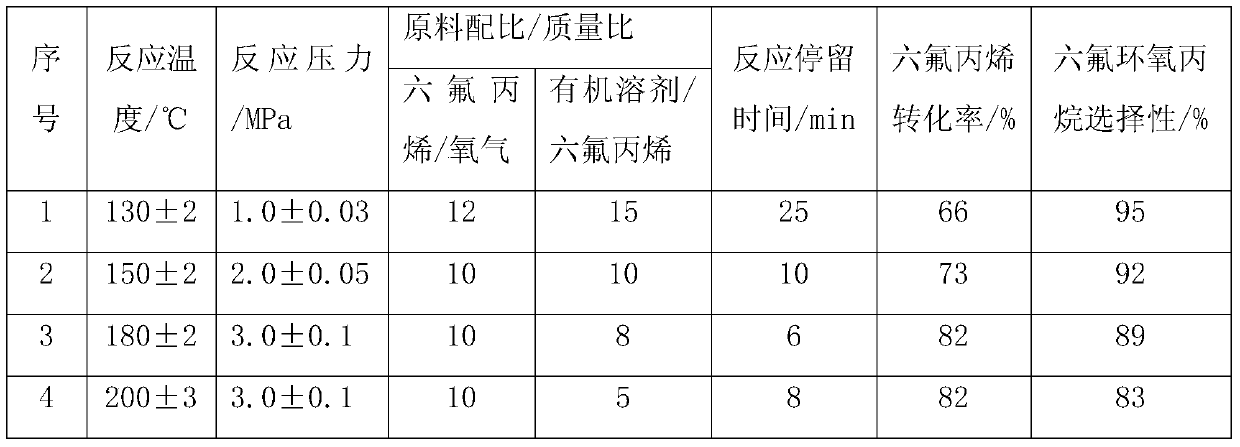

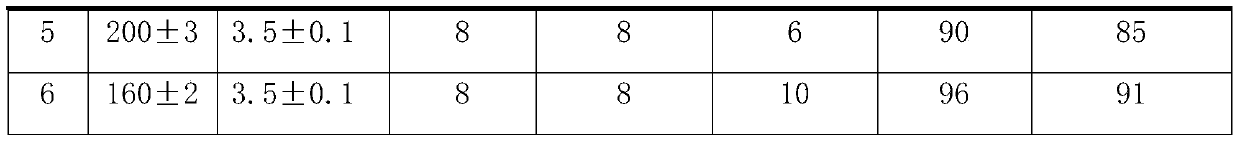

[0026] The mixture of perfluorocycloalkane and fluorocarbon cyclic ether is used as the organic solvent. The hexafluoropropylene (18) coming out from the hexafluoropropylene storage tank (2) is first mixed with the oxygen (19) coming out from the oxygen cylinder (5), and then mixed with the organic solvent (17) coming out from the organic solvent intermediate tank 1 ) are mixed to form a mixed material (20) and enter the microchannel reactor (11). Hexafluoropropylene and oxygen fully react in the microchannel reactor (11), and the resulting reaction product (21) is cooled by the coaxial heat exchanger (12) and then enters the buffer tank (14) for simple separation, and the obtained product is mainly an organic solvent The liquid phase part (22) and the gas phase part (23) that is mainly hexafluoropropylene oxide, wherein: the liquid phase part (22) that is mainly the organic solvent is recycled to the organic solvent intermediate tank ( 1) Continue to use, mainly the gas phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com