Method for preparing tetrahydrofurfuryl alcohol from furfural by aqueous phase hydrogenation

A technology for the preparation of tetrahydrofurfuryl alcohol and hydrogen, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, organic chemistry, etc., and can solve problems such as unstable nickel framework, increased risk, and increased cost , to avoid separation and purification, reduce intermediate steps, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

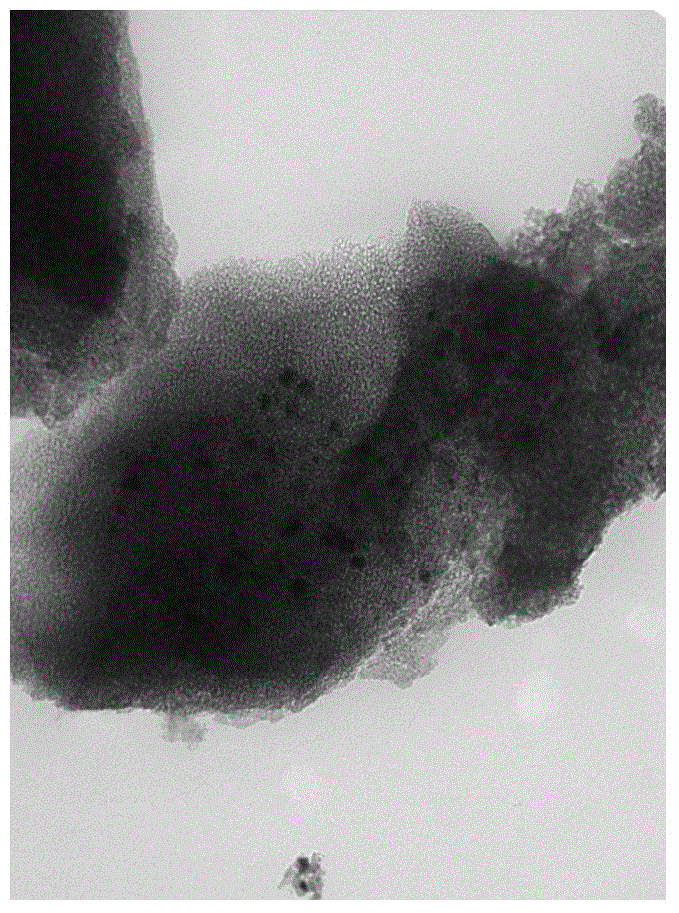

[0018] Catalyst preparation: weigh 4.95g Ni(NO 3 ) 2 ·6H 2 O and add 2.70g of water and stir to dissolve. Add 10g of activated alumina, stir well to form a paste, let stand for 15h, dry at 120°C, then bake at 550°C for 4h, activate at 500°C in a hydrogen atmosphere for 4h before use. figure 1 .

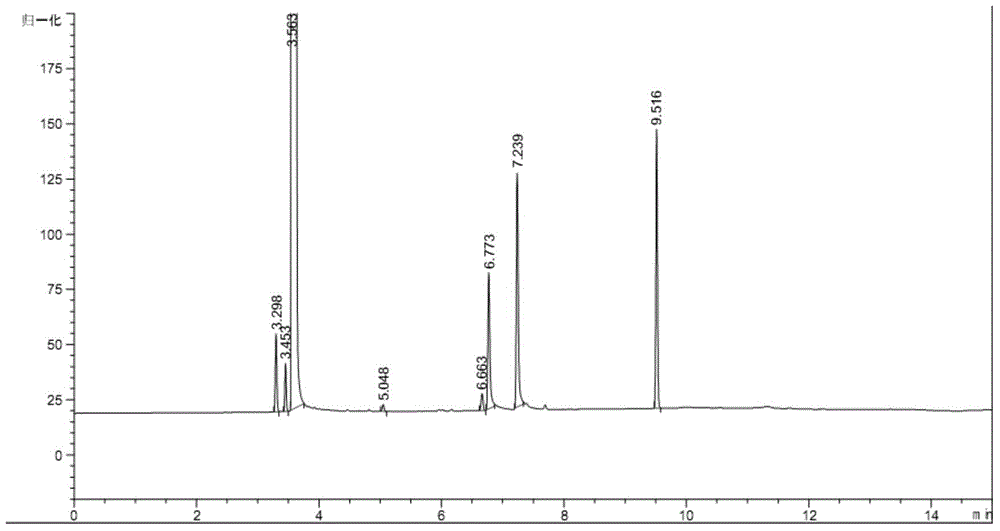

[0019] The catalytic reaction was carried out in a 50ml stainless steel reactor. Add 0.1g of catalyst, 1.5g of furfural, and 8.5g of water into a stainless steel autoclave with a polytetrafluoroethylene lining, and then use Na 2 CO 3 Adjust the pH to 8-9. After closing the reactor, replace the gas in the reactor with hydrogen four times, control the temperature to rise to 140°C with a temperature controller, fill in hydrogen to 4MPa, and start stirring. Keep the pressure constant during the reaction process. After the hydrogenation reaction is completed, after cooling and releasing the pressure, the samples are analyzed by gas chromatography. figure 2 . The reaction time and...

Embodiment 2

[0021] In the nickel nitrate solution in embodiment 1, add 0.50g Co(NO 3 ) 2 ·6H 2 O, other are all with embodiment 1. The results are shown in Table 1.

Embodiment 3

[0023] Change the cobalt nitrate in embodiment 2 into 2.10g Cu(NO 3 ) 2 ·3H 2 O other are all with embodiment 2. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com