Organic rear earth polymer ultraviolet crosslinked exposed waterproof roll and preparation method thereof

A rare earth polymer and waterproof membrane technology, applied in the field of new materials, can solve problems such as poor quality of welding and bonding joints, hidden dangers of reliability, loss of weldability, etc., to improve the dispersion state, increase the degree of dispersion, and expand applications field effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

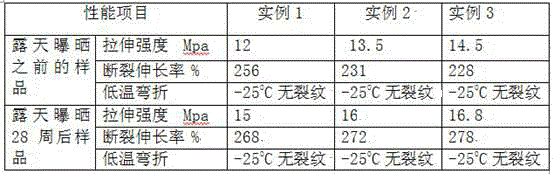

Examples

Embodiment 1

[0029] A method for preparing an organic rare earth polymer ultraviolet crosslinking exposed waterproof membrane, comprising the following steps:

[0030] (1) Preparation of cross-linking slurry: Start the three-roller mill, and add 15 Kg of dioctyl phthalate, 30 Kg of dibutyl phthalate, and 1.5 Kg of rare earth polycarboxylate in the feeding tank in sequence 1 Kg of rare earth oxide, 0.1 Kg of benzophenone, 0.1 Kg of pentaerythritol triacrylate, adjust the roller gap, mix and grind for 15 minutes, check and discharge the fineness below 10 microns, and obtain the crosslinking agent slurry;

[0031] (2) Preparation of blended powder: According to the mass parts, add 50 Kg of polyvinyl chloride, 50 Kg of chlorinated polyethylene, and 3 Kg of composite lead salt stabilizer, enter the high-speed kneader, start stirring for 10 minutes, and add silicon dioxide 12 Kg, precipitated calcium carbonate 28 Kg, continue stirring, temperature rises to 80 O C, adding the crosslinking slurry...

Embodiment 2

[0035] A method for preparing an organic rare earth polymer ultraviolet crosslinking exposed waterproof membrane, comprising the following steps:

[0036] (1) Preparation of cross-linked slurry: Start the three-roller mill, add dioctyl phthalate 10 Kg, dibutyl phthalate 25 Kg, polycarboxylate rare earth 1.5 Kg, rare earth oxide 1.5 Kg, benzophenone 0.1 Kg, pentaerythritol triacrylate 0.15 Kg, adjust the roll gap, mix and grind for 15 minutes, check that the fineness is less than 10 microns and discharge, and obtain the crosslinking agent slurry;

[0037] (2) Preparation of blended powder: According to the mass parts, add 50 Kg of polyvinyl chloride, 50 Kg of chlorinated polyethylene, and 3 Kg of composite lead salt stabilizer, enter the high-speed kneader, start stirring for 10 minutes, and add silicon dioxide 12 Kg; precipitated calcium carbonate 28 Kg; continue to stir, the temperature rises to 80 O C, adding the crosslinking slurry, continuing to stir for 10 minutes to disch...

Embodiment 3

[0041] A method for preparing an organic rare earth polymer ultraviolet crosslinking exposed waterproof membrane, comprising the following steps:

[0042] (1) Preparation of cross-linked slurry: Start the three-roll mill, and add dioctyl phthalate 10 Kg, dibutyl phthalate 20 Kg, polycarboxylate rare earth 1.8 Kg, rare earth oxide 1.5 Kg, benzophenone 0.15 Kg, pentaerythritol triacrylate 0.15 Kg, adjust the roller gap, mix and grind for 15 minutes, check that the fineness is less than 10 microns and discharge, and obtain the crosslinking agent slurry;

[0043] (2) Preparation of blended powder: According to the mass parts, add 50 Kg of polyvinyl chloride, 50 Kg of chlorinated polyethylene, and 3 Kg of composite stabilizer, enter the high-speed kneader, start stirring for 10 minutes, and add 12 Kg of silicon dioxide , Precipitated calcium carbonate 28 Kg, continue to stir, the temperature rises to 80 O C, adding the crosslinking slurry, continuing to stir for 10 minutes to disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com