Glass fiber reinforced polycarbonate (PC) composite material and preparation method thereof

A glass fiber and polycarbonate technology, which is applied in the field of high gloss and high flow glass fiber reinforced polycarbonate composite material and its preparation, can solve the problems of poor molding processability, poor processing fluidity, high viscosity of polycarbonate, etc. Overcome poor surface quality, good processing fluidity and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

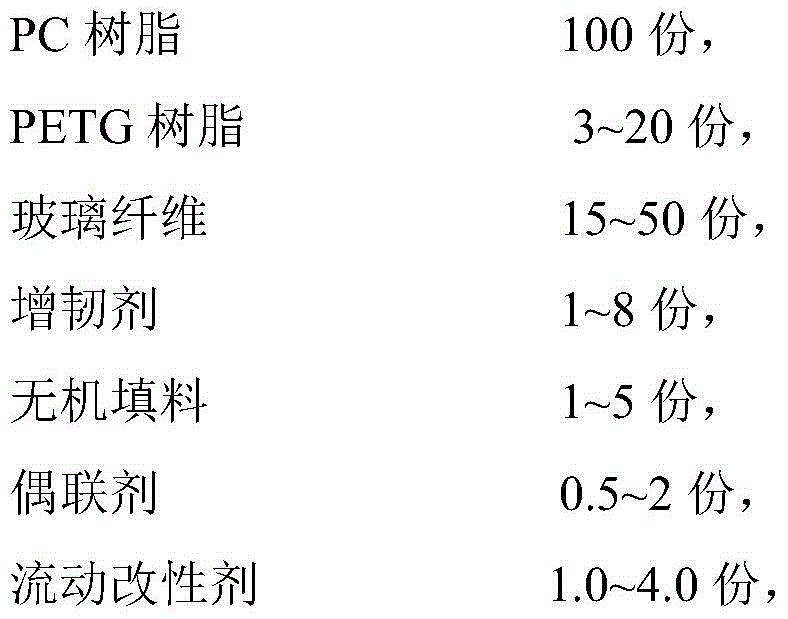

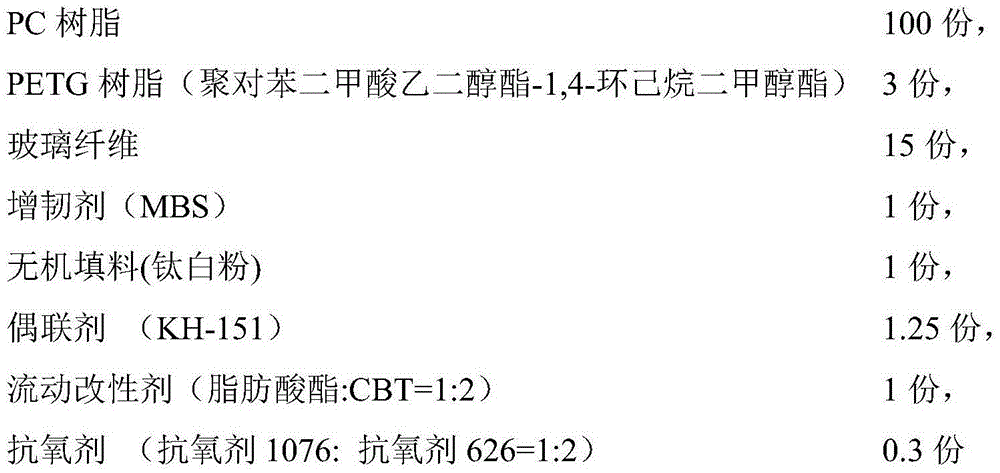

[0027] The content of each component in parts by weight:

[0028]

[0029] The ingredients are carried out according to the above weight parts, PC resin, PETG resin, toughening agent, inorganic filler, coupling agent, flow modifier and antioxidant are put into a high-speed mixer at a mixing temperature of 60°C and a mixing time of 8 minutes. The speed is 500rmp. After high-speed mixing, the material is fed to the hopper of the extruder. The glass fiber is added at the glass fiber port of the extruder. , 270 ℃, 275 ℃, 265 ℃, the main engine speed is 20 Hz, extruded and pelletized by a twin-screw extruder, and drawn into pellets to obtain a high-gloss and high-flow glass fiber reinforced polycarbonate composite material.

[0030] The properties of the samples in this example are: tensile strength of 84.1MPa, bending strength of 150.4MPa, and notched impact strength of simply supported beams of 15KJ / m 2 , the melt index is 30.1g / 10min, the surface of the sample has no floatin...

Embodiment 2

[0032] The content of each component in parts by weight:

[0033]

[0034] The ingredients are carried out according to the above-mentioned parts by weight. PC resin, PETG resin, toughening agent, inorganic filler, coupling agent, flow modifier and antioxidant are put into a high-speed mixer at a mixing temperature of 70 ° C and a mixing time of 5 min. The speed is 600rmp. After high-speed mixing, the material is fed to the hopper of the extruder. The glass fiber is added at the glass fiber port of the extruder. , 260 ℃, 268 ℃, 270 ℃, the main engine speed is 30 Hz, extruded and pelletized by a twin-screw extruder, and pulled into pellets to obtain a high-gloss and high-flow glass fiber reinforced polycarbonate composite material.

[0035] The properties of the samples in this example are: tensile strength of 95MPa, bending strength of 166.2MPa, and notched impact strength of simply supported beams of 18KJ / m 2 , the melt index is 25.6g / 10min, the surface of the sample has ...

Embodiment 3

[0037] The content of each component in parts by weight:

[0038]

[0039] The ingredients are carried out according to the above-mentioned weight parts. PC resin, PETG resin, toughening agent, inorganic filler, coupling agent, flow modifier and antioxidant are put into a high-speed mixer at a mixing temperature of 90 ° C and a mixing time of 3 minutes. The speed is 700rmp. After high-speed mixing, the material is fed to the hopper of the extruder. The glass fiber is added at the glass fiber port of the extruder. , 260 ℃, 268 ℃, 270 ℃, the main engine speed is 40 Hz, extruded and pelletized by a twin-screw extruder, and pulled into pellets to obtain a high-gloss and high-flow glass fiber reinforced polycarbonate composite material.

[0040] The properties of the samples in this example are: tensile strength of 105.8MPa, bending strength of 172.4MPa, and notched impact strength of simply supported beams of 20KJ / m 2 , the melt index is 35g / 10min, the surface of the sample ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com