Plasma-enhanced chemical vapor deposition preparation method of multi-layered graphene film

A multi-layer graphene, plasma technology, applied in gaseous chemical plating, coating, metal material coating process and other directions, can solve problems such as process constraints, high cost, etc., achieve simple and easy-to-control preparation conditions and processes, raw materials Widely sourced and inexpensive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

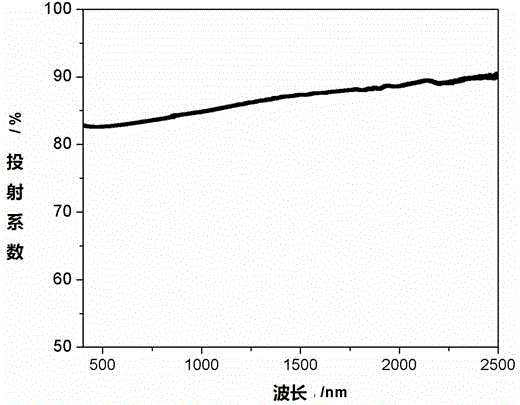

[0018] The preparation of step 2 multilayer graphene film: the amorphous SiC nano film on the quartz or glass substrate obtained in step 1 is used as a buffer layer, and the plasma-enhanced chemical vapor deposition preparation method is used to directly deposit multiple layers on the buffer layer For the graphene film, the deposition temperature is controlled at 450-950 degrees Celsius. The obtained multi-layer graphene film has a uniform thickness and a high visible light transmittance of 60-90%.

[0019] The radio frequency magnetron sputtering method uses 99.999% high-purity argon gas, the sputtering power is controlled at about 50 watts, and the time is controlled at about 30 seconds.

[0020] The described plasma-enhanced chemical vapor deposition preparation method adopts CH 4 and H 2 As a gas source, CH4:H2 in the gas source is 1.5:1, the power is controlled at about 150 watts, the temperature of the quartz or glass substrate is controlled at about 500 degrees ...

Embodiment 1

[0023] (1) Deposit SiC nano-film on quartz or glass substrate: use 99.9% SiC ceramic target, background vacuum 3 mPa, sputtering gas 99.999% high-purity argon, sputtering power 50 watts, time 30 Seconds, the temperature of the glass substrate is 400 degrees Celsius. The resulting amorphous film had a thickness of 3 nm.

[0024] (2) Preparation of multilayer graphene film: use the glass sheet prepared in step (1) as the substrate, use CH4 and H2 composite gas as the gas source, and the ratio of the composite gas in the gas source is CH4:H2=1.5:1 , the power is 150 watts, the substrate temperature is 500 degrees Celsius, the time is 10 minutes, and the obtained film thickness is 5 nm.

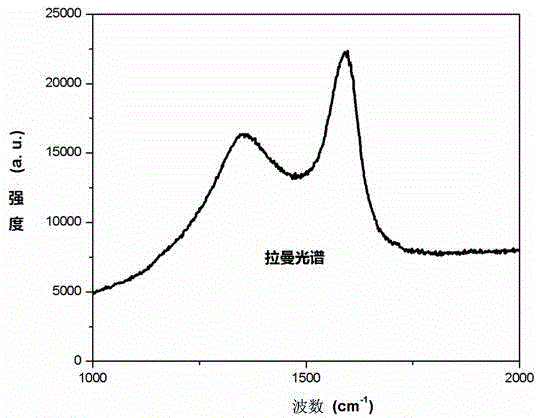

[0025] The optical transmittance of the multilayer graphene film that present embodiment makes is as follows figure 1 As shown, the raman spectrum is as figure 2 shown. From figure 1 It can be seen that the visible light transmittance of the film is greater than 80%, while figure 2 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com