A kind of preparation method of antibacterial polyethylene terephthalate composite fiber film

A polyethylene terephthalate, composite fiber film technology, applied in the direction of chemical characteristics of fibers, single-component polyester rayon, rayon manufacturing, etc., can solve problems such as agglomeration, achieve stable performance, method Simple, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

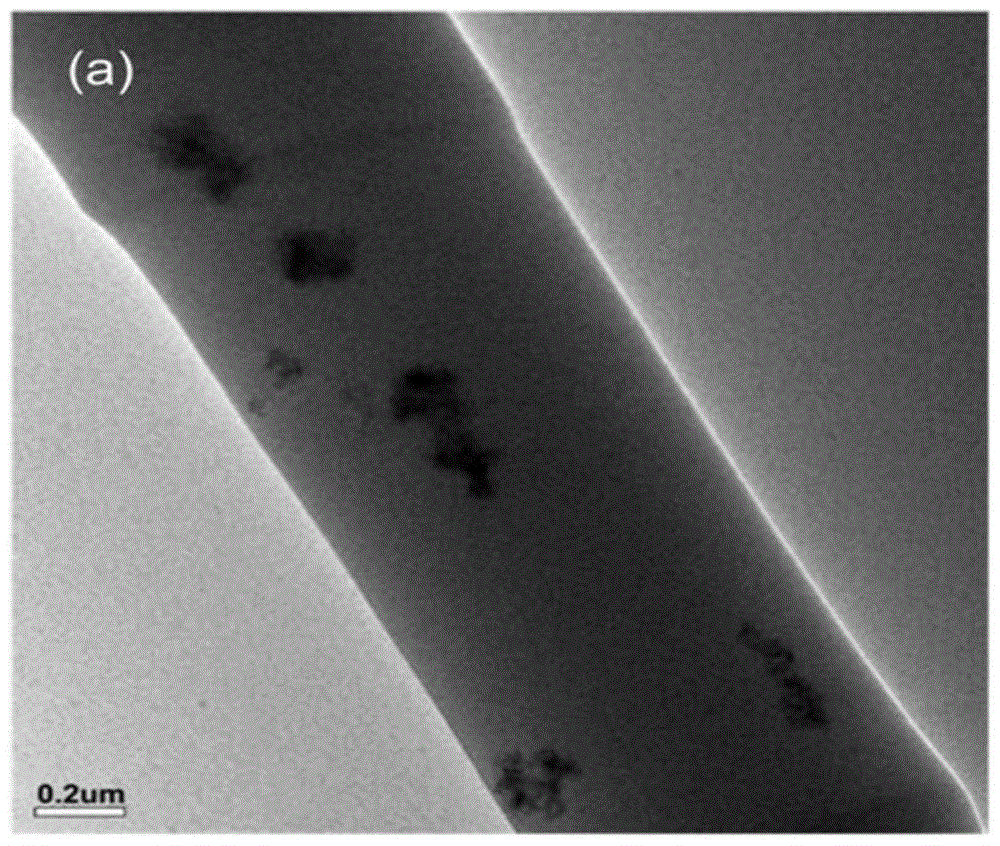

[0028] Measure 2ml of CH 2 Cl 2 and 2ml of CF 3 The COOH solution was stirred evenly in the Erlenmeyer flask and used as a solvent. Weigh 0.2g of PET (Mw=18,000) chips and 0.2g of PHEB powder (Mw=23,700) and dissolve them in the above solvent, and stir magnetically at room temperature until PET and PHEB are completely dissolved. Weigh 0.02 g of titanium dioxide nanoparticles (100% anatase type, particle size ≤ 25 nm), add to the above PET / PHEB solution, and magnetically stir for 4 hours to obtain an electrospinning solution, which is ready for use.

[0029] Inject the electrospinning liquid into the glass syringe, adjust the voltage in the electrospinning conditions to 14.5KV, the spinning distance is 15cm, and the spinning speed is 0.5ml / h, and the electrospinning PET / TiO 2 / PHEB composite fiber membrane.

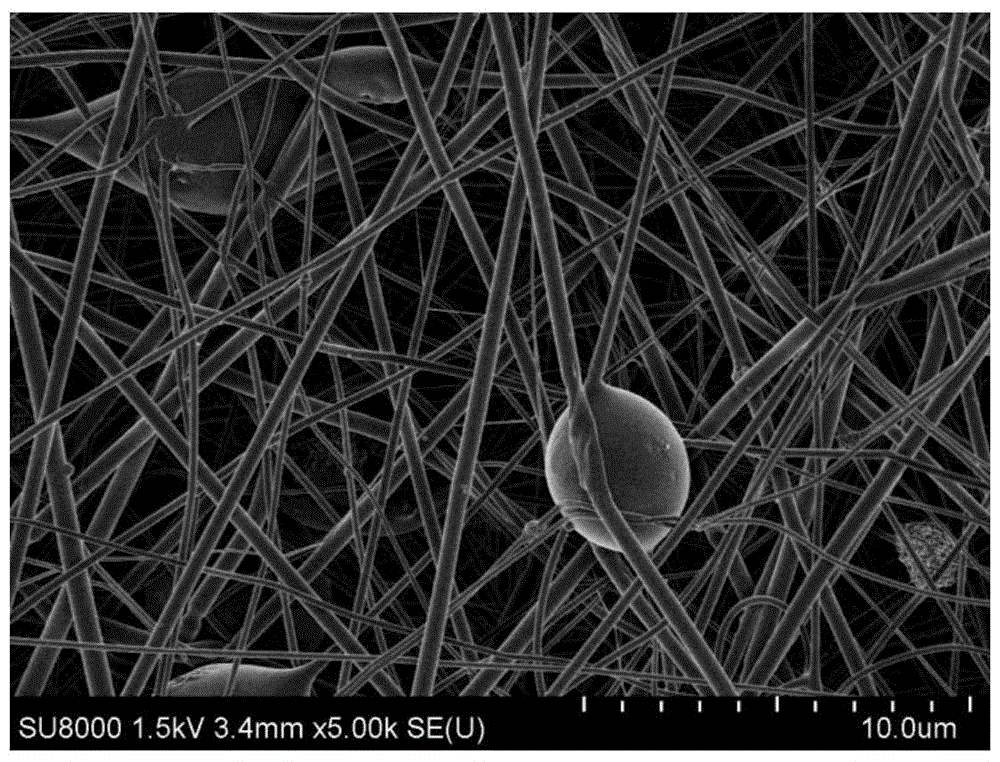

[0030] Scanning electron microscopy (Hitachi SU8000Series) was used to measure the microscopic morphology of the fiber membrane, and the test results were as follows: ...

Embodiment 2

[0032] Measure 2ml of CH 2 Cl 2 and 2ml of CF 3 The COOH solution was stirred evenly in the Erlenmeyer flask and used as a solvent. Weigh 0.28g of PET (Mw=18,000) chips and 0.12g of PHEB powder (Mw=23,700) and dissolve them in the above solvent, and stir magnetically at room temperature until PET and PHEB are completely dissolved. Weigh 0.02 g of titanium dioxide nanoparticles (100% anatase type, particle size ≤ 25 nm), add to the above PET / PHEB solution, and magnetically stir for 4 hours to obtain an electrospinning solution, which is ready for use.

[0033] Inject the electrospinning solution into the glass syringe, adjust the voltage in the electrospinning conditions to 14KV, the spinning distance is 12.5cm, and the spinning speed is 0.75ml / h, and the electrospun PET / TiO 2 / PHEB composite fiber membrane.

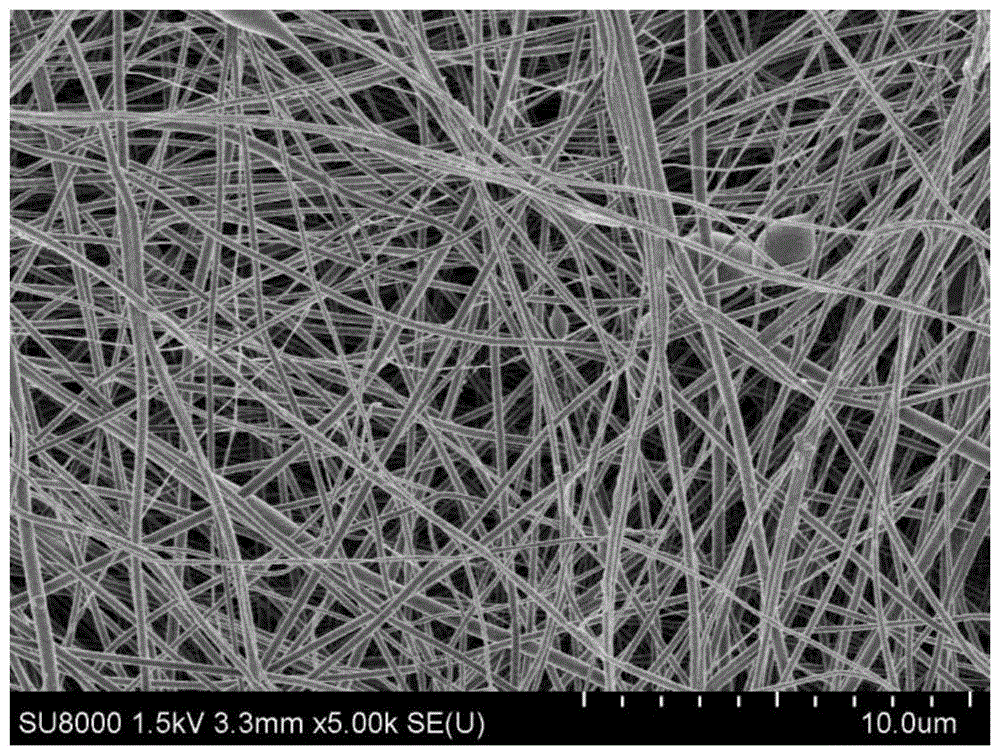

[0034] After testing, compared with Comparative Example 1, the titanium dioxide agglomeration phenomenon has been greatly improved, but not as obvious as in Example 1...

Embodiment 3

[0036] Measure 2ml of CH 2 Cl 2 and 2ml of CF 3The COOH solution was stirred evenly in the Erlenmeyer flask and used as a solvent. Weigh 0.36g of PET (Mw=18,000) sliced particles and 0.04g of PHEB powder (Mw=23,700) and dissolve them in the above solvent, and stir magnetically at room temperature until PET and PHEB are completely dissolved. Weigh 0.02 g of titanium dioxide nanoparticles (100% anatase type, particle size ≤ 25 nm), add to the above PET / PHEB solution, and magnetically stir for 4 hours to obtain an electrospinning solution, which is ready for use.

[0037] Inject the electrospinning solution into the glass syringe, adjust the voltage in the electrospinning conditions to 15KV, the spinning distance is 10cm, and the spinning speed is 1ml / h, and the electrospun PET / TiO 2 / PHEB composite fiber membrane.

[0038] After testing, compared with Comparative Example 1, the titanium dioxide agglomeration phenomenon has been greatly improved, but not as obvious as in Ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com