Method for preparing sea-island ultrafine fiber PU (polyurethane) leather base cloth by using additive-type water proofing, oil repellent and antifouling finishing agent

A three-proof finishing agent and ultra-fine fiber technology, which is applied in the direction of fiber type, fiber treatment, chemical instruments and methods, etc., can solve the problems of three-proof performance decline, etc., and achieve a broad market situation, excellent three-proof effect, and soft hand feeling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add additive-type three-proof finishing agent to conventional solvent-based polyurethane, additives, color paste, dispersant, solvent and other raw materials, mix evenly to form a wet impregnation slurry, and then use nylon 6 and polyethylene as raw materials for sea-island shorts The non-woven fabric formed by needle punching is soaked in wet slurry, then coagulated and washed with water, and then the polyethylene is extracted in hot toluene, expanded and dried, oiled and rubbed to obtain three anti-microfibers PU leather base cloth;

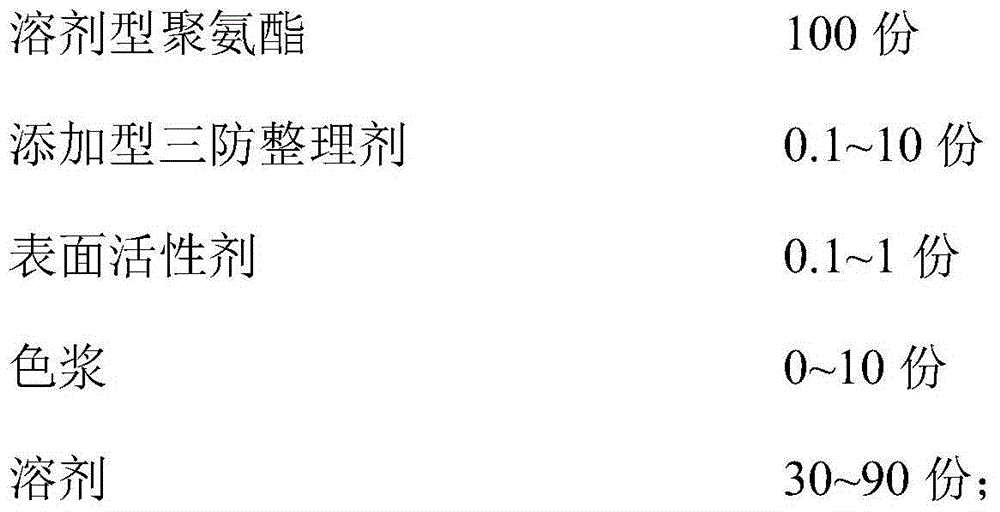

[0026] For the additive type dipping slurry, the parts by weight of each component are as follows:

[0027]

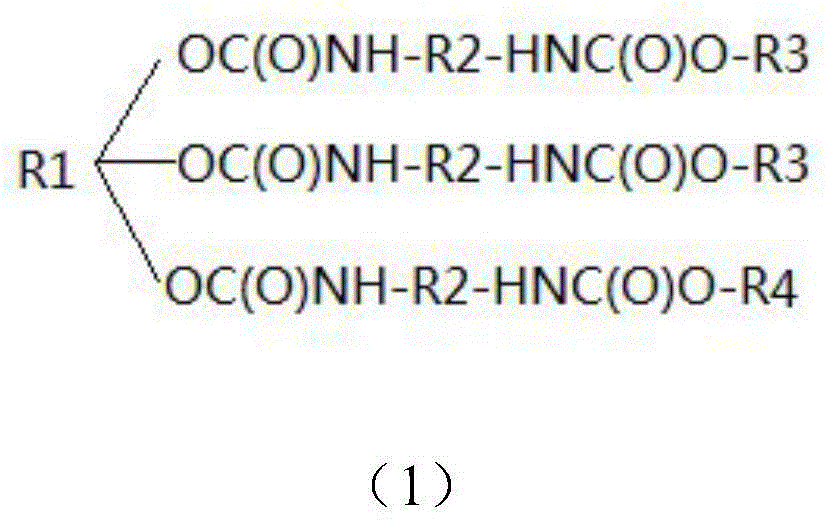

[0028] The preparation method of described additive type three anti-finishing agent A is as follows:

[0029] Under the protection of nitrogen, add 50g of perfluoroalkyl ethyl alcohol, 50g of toluene diisocyanate, 2g of trimethylolpropane, 30g of stearyl alcohol, and 100g of dimethylformamide into the reaction vessel, and rea...

Embodiment 2

[0041] Add additive-type three-proof finishing agent to conventional solvent-based polyurethane, additives, color paste, dispersant, solvent and other raw materials, mix evenly to form a wet impregnation slurry, and then use nylon 6 and polyethylene as raw materials for sea-island shorts The non-woven fabric formed by needle punching is soaked in wet slurry, then coagulated and washed with water, and then the polyethylene is extracted in hot toluene, expanded and dried, oiled and rubbed to obtain three anti-microfibers PU leather base cloth;

[0042] The impregnated slurry batching technology, non-woven needle punching technology, and impregnated weight reduction technology can all refer to the literature: Qu Jianbo: "Synthetic Leather Technology" P20-P225 processing technology reported.

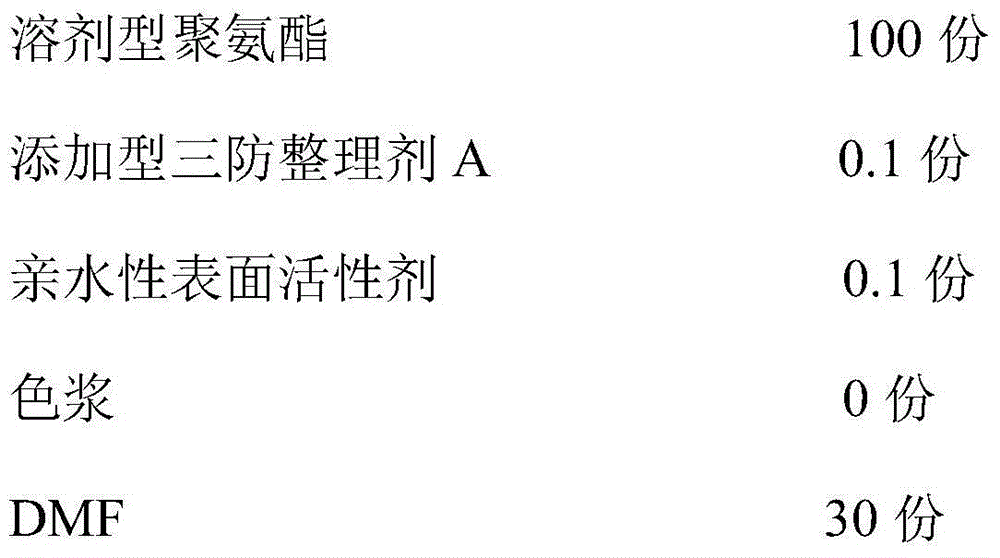

[0043] For the additive type dipping slurry, the parts by weight of each component are as follows:

[0044]

[0045] The preparation method of described additive type three anti-finishin...

Embodiment 3

[0059] Add additive-type three-proof finishing agent to conventional solvent-based polyurethane, additives, color paste, dispersant, solvent and other raw materials, mix evenly to form a wet impregnation slurry, and then use nylon 6 and polyethylene as raw materials for sea-island shorts The non-woven fabric formed by needle punching is soaked in wet slurry, then coagulated and washed with water, and then the polyethylene is extracted in hot toluene, expanded and dried, oiled and rubbed to obtain three anti-microfibers PU leather base cloth;

[0060] The impregnated slurry batching technology, non-woven needle punching technology, and impregnated weight reduction technology can all refer to the literature: Qu Jianbo: "Synthetic Leather Technology" P20-P225 processing technology reported.

[0061] For the additive type dipping slurry, the parts by weight of each component are as follows:

[0062]

[0063]

[0064] The preparation method of described additive type three a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com