Analysis system and method for measuring impurity components in high-purity gas

An analysis system and high-purity gas technology, which can be used in analytical materials, measuring devices, material separation, etc., can solve problems such as the inability to meet the requirements for the determination of impurity components in high-purity gases, and achieve the goal of reducing the cost of measurement and improving the efficiency of measurement and analysis. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

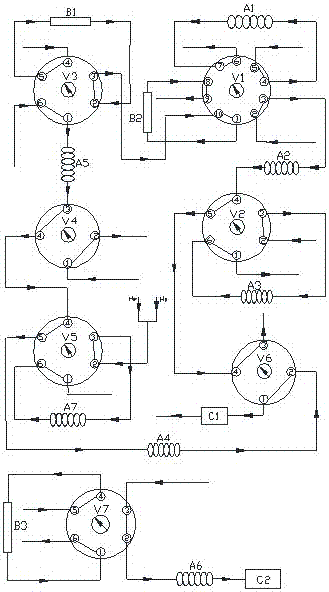

[0021] Such as figure 1 As shown, the analysis system of the present invention for measuring impurity components in high-purity gas includes a ten-way valve V1, a first six-way valve V2, a second six-way valve V3, a third six-way valve V5, a fourth six-way valve V7, and a A four-way valve V4, a second four-way valve V6, the first column A1, the second column A2, the third column A3, the fourth column A4, the fifth column A5, the sixth column A6, deoxygenation Column A7, the first sample loop B1, the second sample loop B2, the third sample loop B3, the helium ionization detector C1 and the hydrogen flame detector C2, the first port of the ten-way valve A1 is connected to the The input end of the second sample quantitative loop B2, the eighth port are connected to the output end of the second sample quantitative loop B2, the fourth port is connected to the input end of the first chromatographic column A1, and the seventh port is connected to the first The output end, the second p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com