Manufacturing method of diamond saw chain

A technology for diamond saws and manufacturing methods, which is applied in the manufacture of diamond saw chains and the field of manufacturing diamond saw chains, and can solve the problems of high welding costs, adverse effects on the cutting performance of the cutter head, and inconsistency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

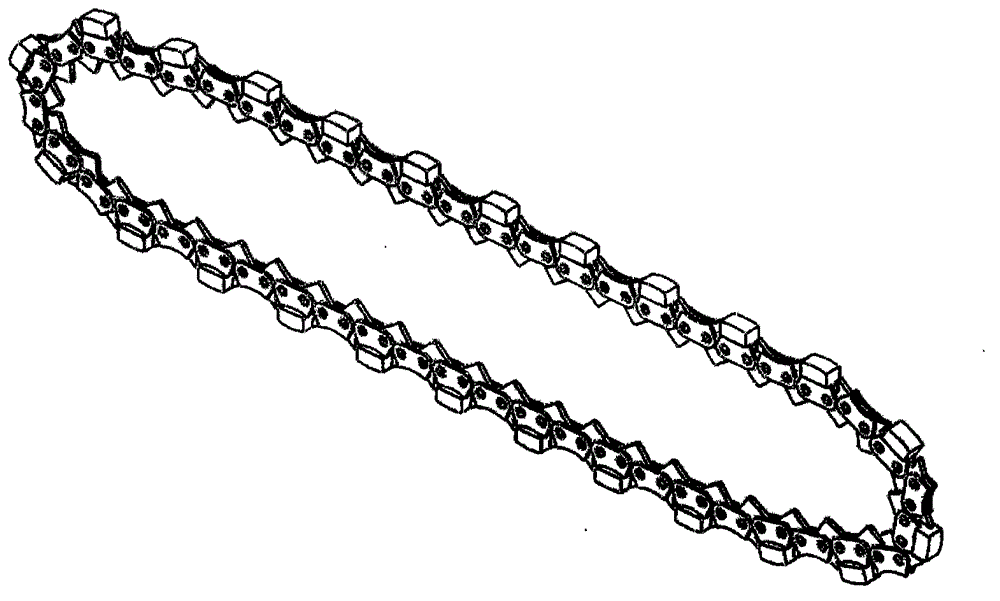

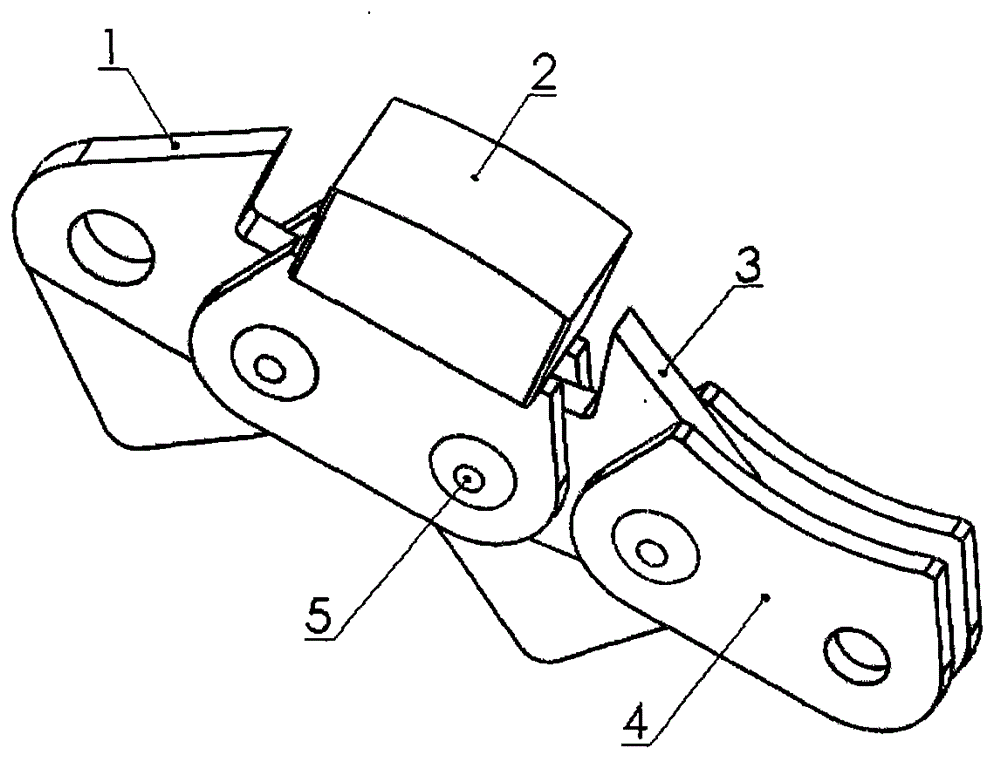

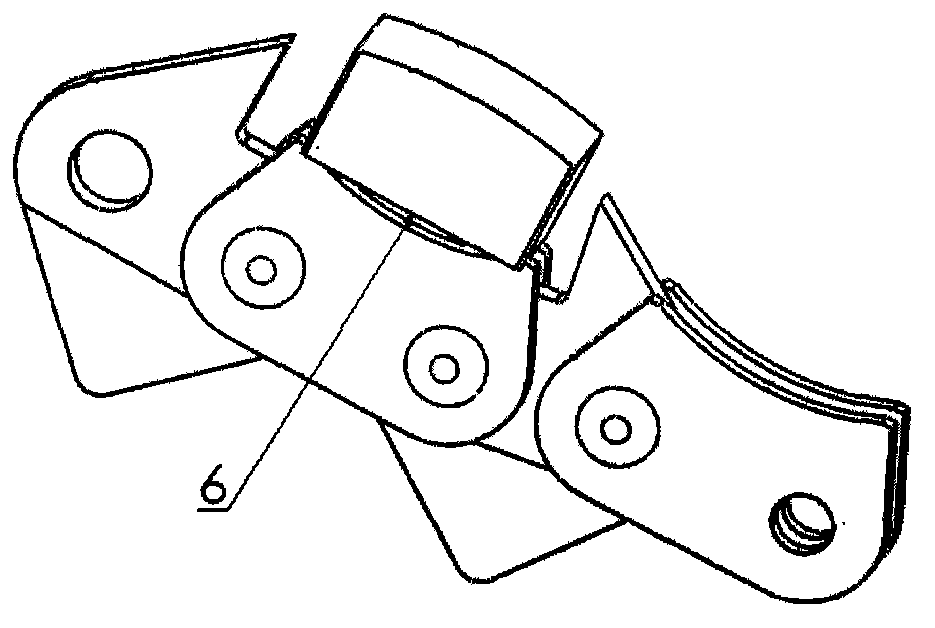

[0024] The manufacturing method of the diamond saw chain, the diamond saw chain is formed by riveting several chain link units, and the chain link unit is mainly composed of the tooth piece I (1), the diamond cutter head (2 ), said gear piece II (3), said four connecting pieces (4) and four said chain shafts (5) constitute. The diamond cutter head (2) has the steel core (11), the steel core (11) has serrations, and the serrations on the steel core (11) are beneficial to enhance the bonding strength with the metal powder after sintering. The tooth piece I (1) and the tooth piece II (3) are the same part, and the tooth piece I (1) and the tooth piece II (3) have the surface I (8) and the tooth piece II (3). The surface II (9), the surface I (8) and the surface II (9) are symmetrical, and the tooth piece I (1) and the tooth piece II (3) have the protective teeth (10) . The cutter head mold is made of graphite, and the inner bottom surface of the cutter head mold has the steel c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com