Precision laser cutting and micro-hole machining device

A laser cutting and micro-hole processing technology, applied in the field of laser applications, can solve problems such as low production efficiency, complicated processing procedures, and rough hole edges, so as to improve processing efficiency, avoid bottom damage, and improve processing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

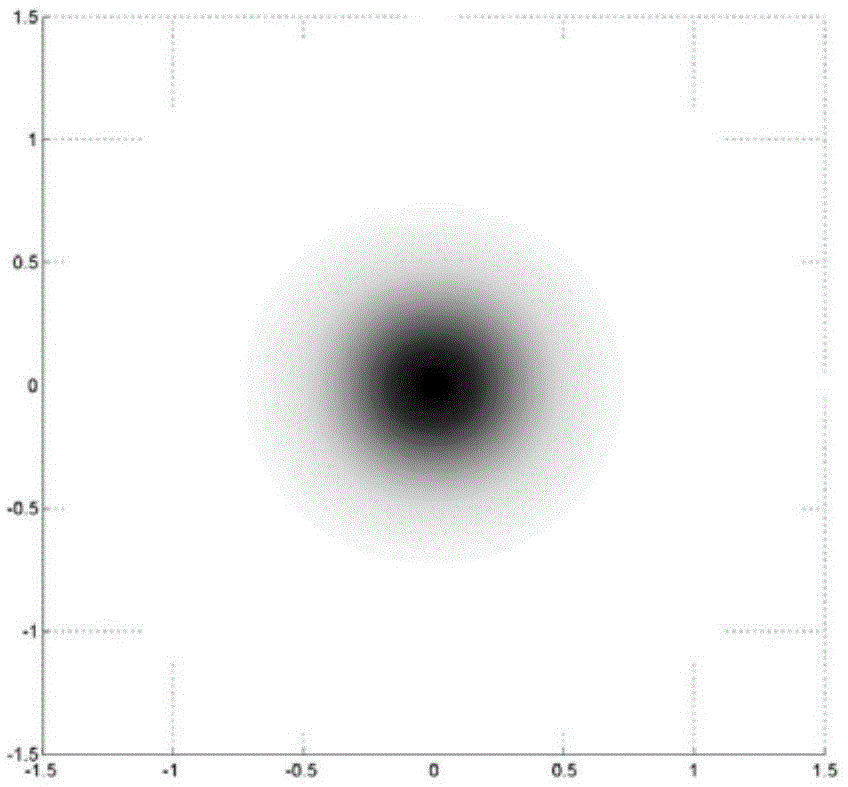

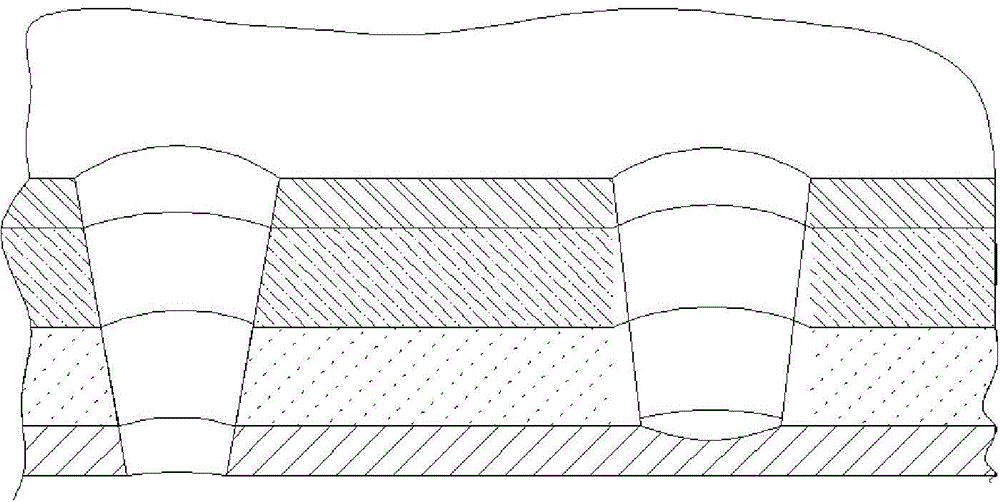

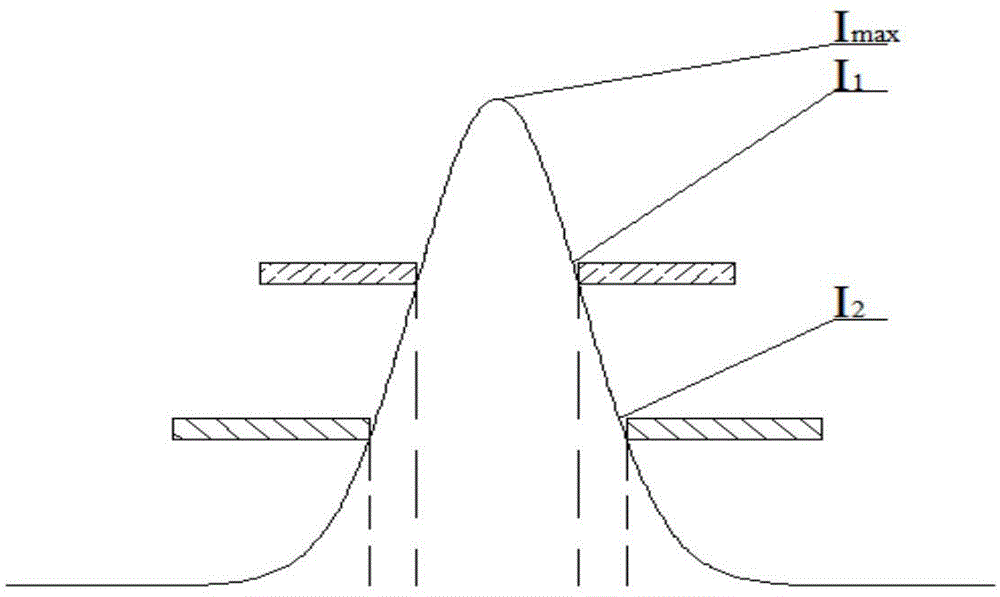

[0030] Such as Figure 5 , 6As shown, the precision laser cutting and microhole processing device of the present embodiment includes a laser 1 for generating Gaussian laser, a beam expander 2 arranged in sequence along the optical path, a rotatable front reflector 3, and a rotatable rear reflector. mirror 4 and focusing lens 5, at least one set of beam shaping system 6 for shaping the Gaussian laser beam into a flat-top laser beam and at least one set of beam shaping system 6 for optimizing the Gaussian laser beam are provided between the front end reflector 3 and the rear end reflector 4 The beam optimization system 7 of the beam, the front reflector 3 is used to selectively reflect the Gaussian laser beam after the beam expander 2 into the beam shaping system 6 or the beam optimization system 7, and the rear reflector 4 is used to convert the Gaussian laser beam from The laser beam emitted by the beam shaping system 6 or the beam optimizing system 7 is reflected into the fo...

Embodiment 2

[0035] Such as Figure 8 As shown, the overall structure of the precision laser cutting and microhole processing device of this embodiment is the same as that of Embodiment 1, the difference is that the precision laser cutting and microhole processing device of this embodiment includes two sets of different beam shaping In system 6, Gaussian laser beams are shaped by two different sets of beam shaping systems 6 to obtain flat-topped laser beams with different spot diameters, so that the processing of micro through holes and blind holes with different diameters can be realized. In order to obtain flat top laser beams with different spot diameters, there are at least the following three methods: one is to use different shaping devices 62, such as diffractive optical shaping devices, shaping devices that use refraction to change the light intensity distribution of beams, non- Select two different shaping devices among the spherical lens shaping device and the lens group shaping d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com