Steam heating type rapid heat cycle molding injection mold

A heating technology for injection molds, applied in the field of steam-heated high-gloss injection molds, can solve the problems of reducing mold heat capacity, low heat cycle efficiency, and high mold cost, and achieve good economic benefits, high heat cycle efficiency, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to better understand the technical solution of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

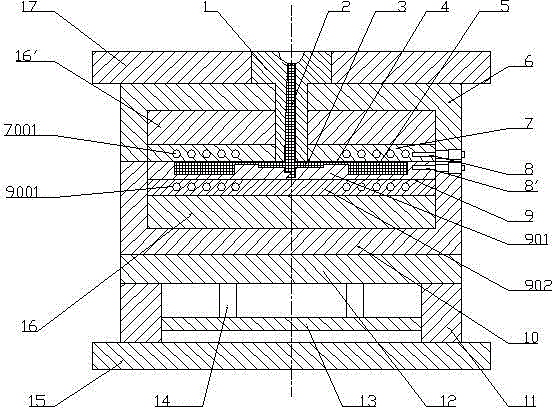

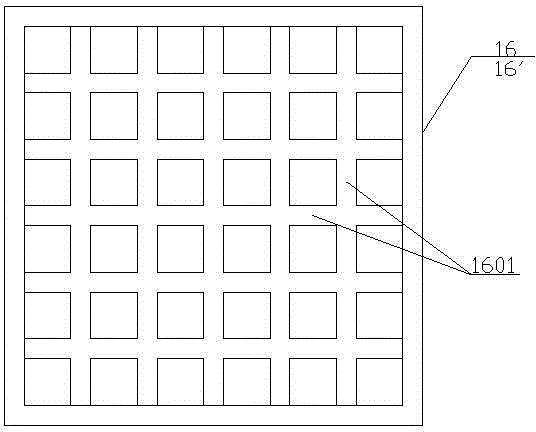

[0037] Such as figure 1 As shown, a steam-heated high-gloss injection mold disclosed by the present invention includes a core plate 7 and a cavity plate 9, and the cavity plate and the core plate are respectively connected with supporting plates 16 and 16 ′. The support plates 16 and 16' adopt a plurality of ordinary steel plates 1601 with poor thermal conductivity, and are connected into a grid-like structure through criss-cross connections. The grid-like structure is composed of regular polygonal meshes, and the shape, size and distribution of the meshes are It is necessary to optimize the design to ensure the performance requirements of all aspects of the mold. The cavity plate 9 is composed of a molding layer 901 and a matrix layer 902, and the thickness of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com