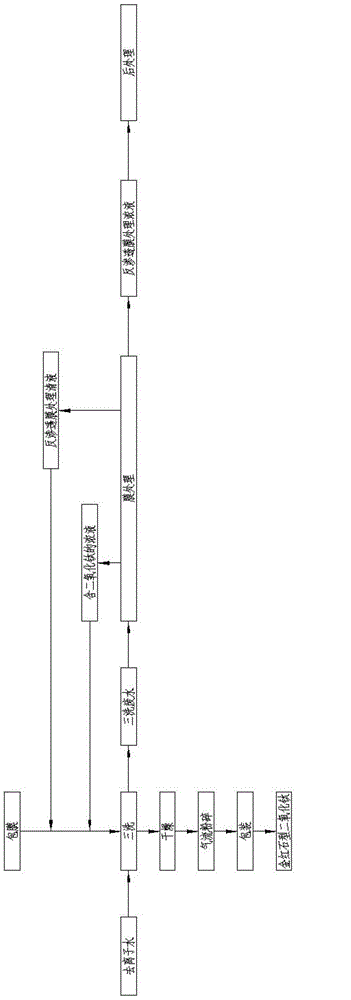

Green and environment-friendly sulfuric acid method titanium dioxide production device and process

A kind of green environmental protection, production process technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., to achieve the effect of improving the recovery rate of titanium dioxide, reducing emissions, and reducing environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

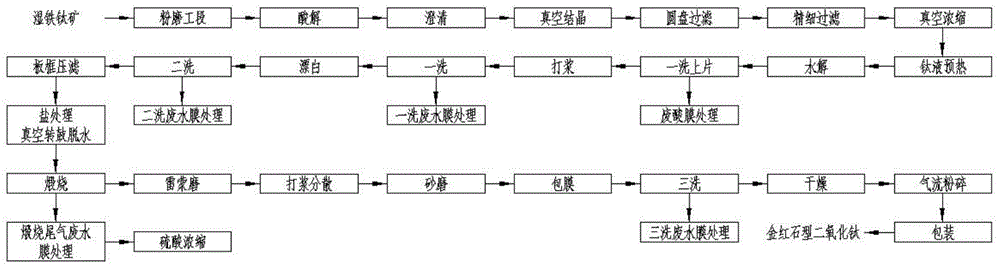

Method used

Image

Examples

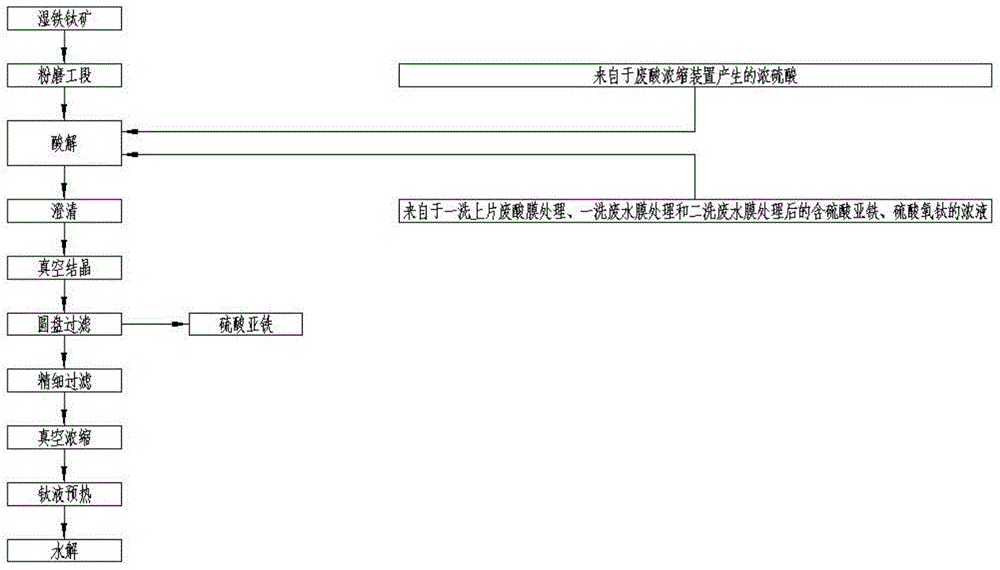

Embodiment 1

[0070] The concentration of titanium in the waste acid after one wash is 9.22g / L, the concentration of ferrous ion is 45g / L, and the content of sulfuric acid is 20%. The waste acid is firstly treated by a microfiltration membrane with a precision of 200nm and a transmembrane pressure difference of 0.2MPa. After the membrane treatment, the concentrated solution containing metatitanic acid is returned to the first washing tank, and the titanium concentration in the clear solution after the membrane treatment is 2g / L. The supernatant liquid treated by the microfiltration membrane continues to be treated with an acid-resistant membrane, and the operating pressure is 3.8MPa. After acid-resistant membrane treatment, the concentrated solution containing ferrous sulfate and titanyl sulfate is returned to the acid hydrolysis pot. The concentration of titanium in the clear solution after single-stage acid-resistant membrane treatment is 140mg / L, the concentration of ferrous ion is 2.25g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com