Sewage processing high-efficiency antifoaming agent

A technology for sewage treatment and defoaming agent, applied in the field of defoaming agent production and high-efficiency defoaming agent for sewage treatment, can solve the influence of the increase of COD value of system wastewater, unsatisfactory defoaming effect and foam suppression time, defoaming and foam suppression Problems such as poor effect, to achieve the effect of high cost performance, no adverse side effects, good anti-foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

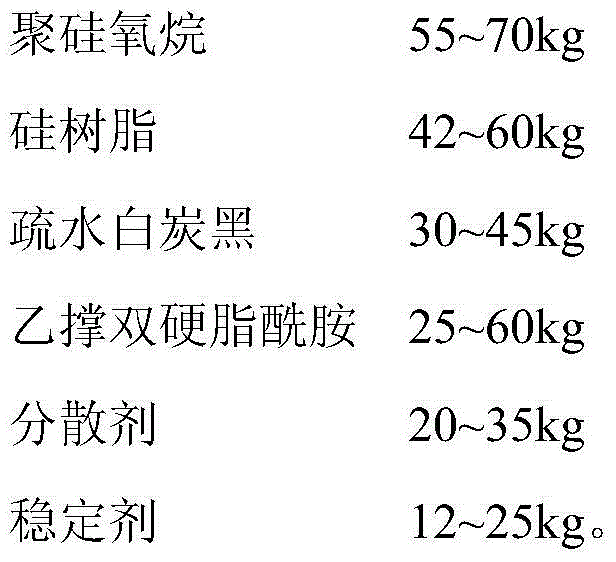

Method used

Image

Examples

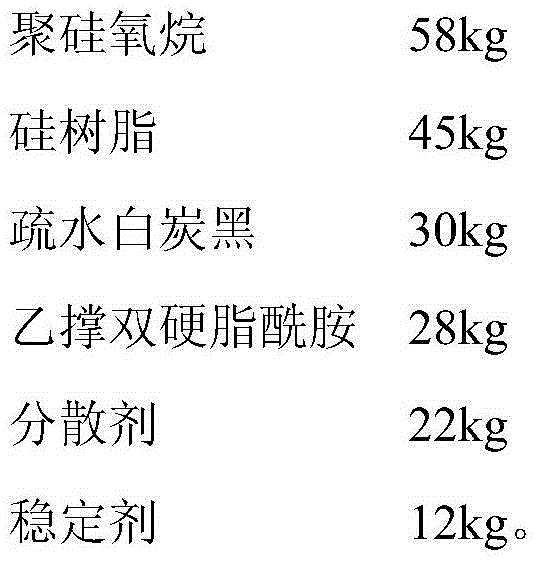

Embodiment 1

[0019]

[0020] The preparation method is as follows: add polysiloxane, silicone resin and hydrophobic white carbon black into the reaction kettle according to the metering, keep it at 200°C for 8 hours, and grind the obtained product through a colloid mill; mix the product obtained in the previous step with ethylene bis stearamide , dispersant and stabilizer are mixed thoroughly according to the measurement, and at 60-90°C, slowly add water to cause phase inversion, and the obtained milky white product is ground by a colloid mill to obtain a defoamer.

[0021] The performance of the provided defoamer is equivalent to that of the existing defoamers, or even better than the existing defoamers. It can improve its defoaming effect, defoaming speed and foam suppression time. Processing costs. Good water solubility, easy to disperse in water, and can be well compatible with liquid products.

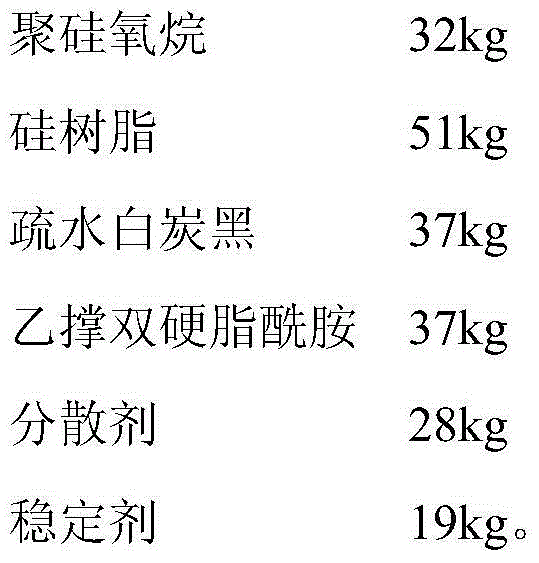

Embodiment 2

[0023]

[0024] The preparation method is the same as above.

[0025] High efficiency at very low concentration, stable and effective under extreme pH conditions, good stability, not easy to break emulsion, good dispersibility, excellent water solubility, prevent microbial growth, non-toxic, non-flammable.

Embodiment 3

[0027]

[0028] The preparation method is the same as above.

[0029] Alkali and acid resistance, fast defoaming speed, long foam suppression time, high efficiency, non-toxic, non-corrosive, and no adverse side effects. Low COD, low consumption, is a kind of environmental protection.

[0030] This product is a high-efficiency defoamer in water phase system, easy to disperse in water and easy to use. It has rapid defoaming effect and anti-foaming function in a wide range of pH and temperature. It is well compatible with various additives, can quickly eliminate foam, and has the effect of preventing foam regeneration. It is widely used in various sewage treatment, various circulating water, printing pulping, bleaching and dyeing, biotin fermentation, water-based additives processing, oil field industry, paper making, pesticides, washing, adhesives, ink coatings, sewage treatment and other fields.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com