A kind of recombinant Bacillus subtilis with high pullulanase production and its construction method

A Bacillus subtilis and pullulanase technology is applied in the field of Bacillus subtilis recombinant strain construction, and can solve the problems of weak acid resistance, low yield, and low thermal stability of pullulanase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: Construction of recombinant plasmid pGE-BPB

[0030] The gene operon BPB that is used for the expression of pullulanase comprises a gene sequence and terminator of the coding BnPulB (its nucleotide sequence shown in SEQ ID NO.3) by tandem promoter Pga2 and codon optimization Sequence T-aprE, wherein Pga2 is composed of promoter PyxiE and RNA stabilizing factor CryIIIA (the nucleotide sequence of Pga2 is shown in SEQ ID NO.2), the sequence immediately after the start codon ATG is SPamyL, and the relevant nuclear The nucleotide sequence was generated by Jinweizhi Biotechnology Co., Ltd. using DNA chemical synthesis method to generate gene fragments to construct the gene operon BPB, and then clone the gene operon BPB into the plasmid pUC57 to generate pUC57-BPB. BPB with Eco RI sites at both ends was obtained by PCR obtained by the following method:

[0031]Upstream primer: CAAGGAATTCCATGGCCGGCCGACCGGG

[0032] Downstream primer: AGCAGAATTCTTATTTTACCATCAGAT...

Embodiment 2

[0050] Embodiment 2: the molecular biological operation of the recombinant Bacillus subtilis producing pullulanase

[0051] 1. Transfer pGE-BPB into Bacillus subtilis 168 competent cells.

[0052] First prepare the chemically competent cells of Bacillus subtilis, which is prepared by two culture methods: activate Bacillus subtilis 168 on LB agar plate, take a single clone to culture in LB, transfer to SP I at a volume ratio of 5% culture medium at 30°C until the logarithmic growth phase, then transferred to the SP II medium at the same volume ratio and cultured to the logarithmic growth phase, centrifuged to collect the cells, and then resuspended the cell pellet into the SP II medium to form Concentrated competent cells with an OD600 of approximately 5.0. The formula of SPI medium in the present embodiment is: 0.02% casein acid hydrolyzate, 0.1% yeast powder, 0.5% glucose, 0.2% (NH 4 ) 2 SO 4 , 1.4% K 2 HPO 4 ·3H 2 O, 0.6% KH 2 PO 4 , 0.1% sodium citrate and 0.02% Mg...

Embodiment 3

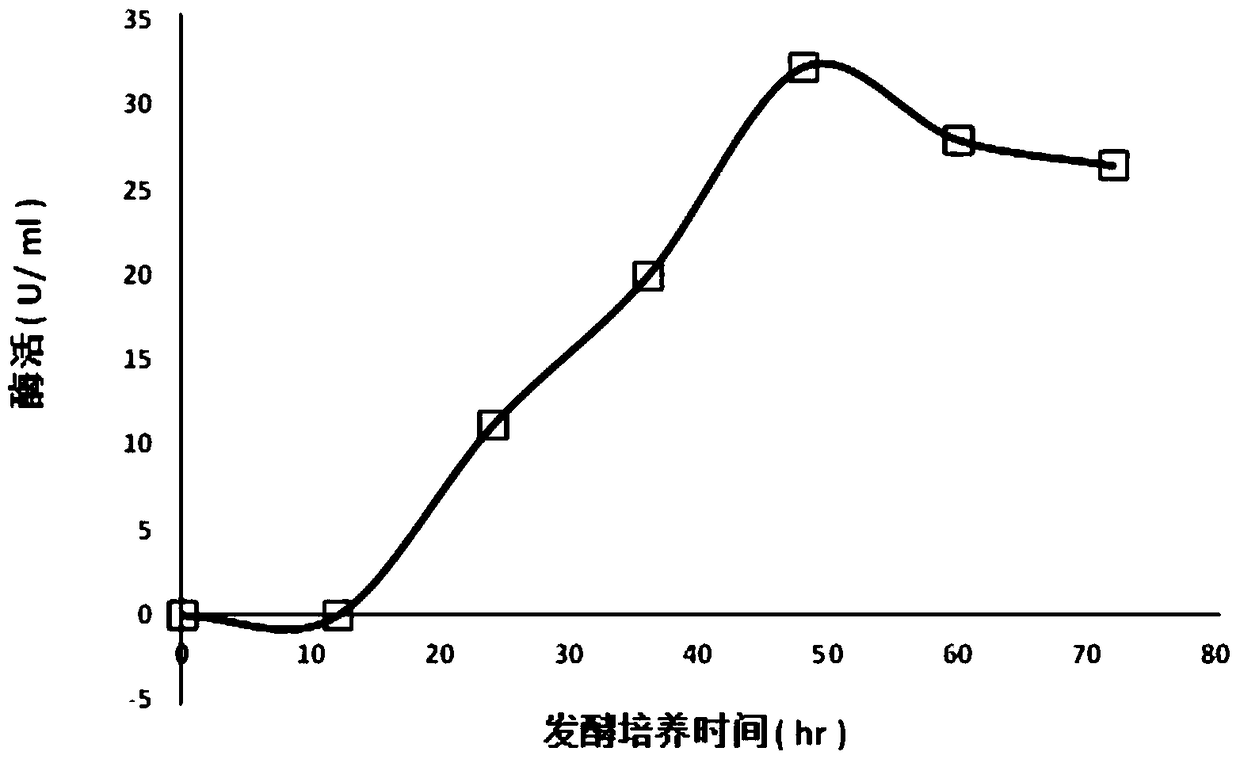

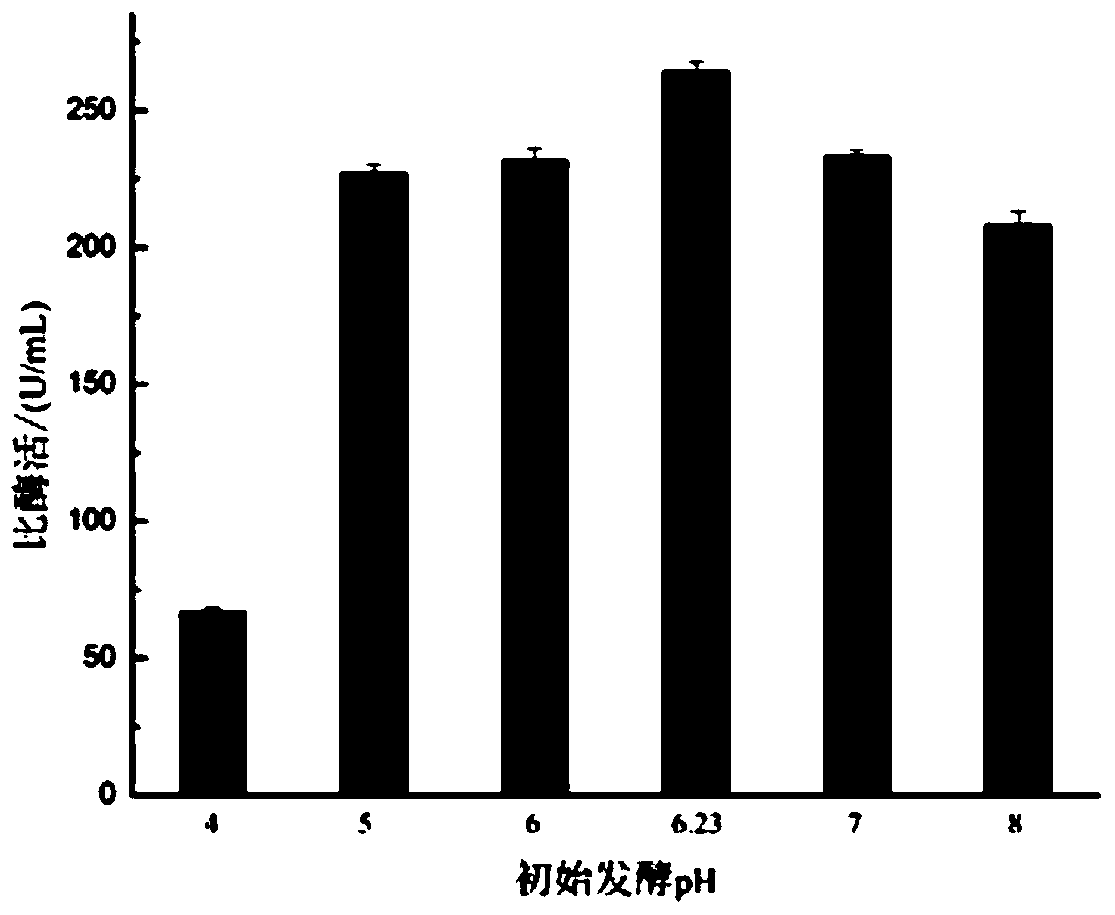

[0078] Embodiment 3: fermentative production of pullulanase by recombinant Bacillus subtilis strain CH-1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com