Mud concentration type shield tunneling construction method for shield tunneling machine

A shield machine, mud thickening technology, applied in wellbore lining, tunnel lining, underground chambers, etc., can solve problems such as the inability to maintain the stability of the excavation surface, the instability and collapse of the excavation surface, and the increase in engineering costs. , to achieve the effect of eliminating harmful gas hazards, improving construction accuracy and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

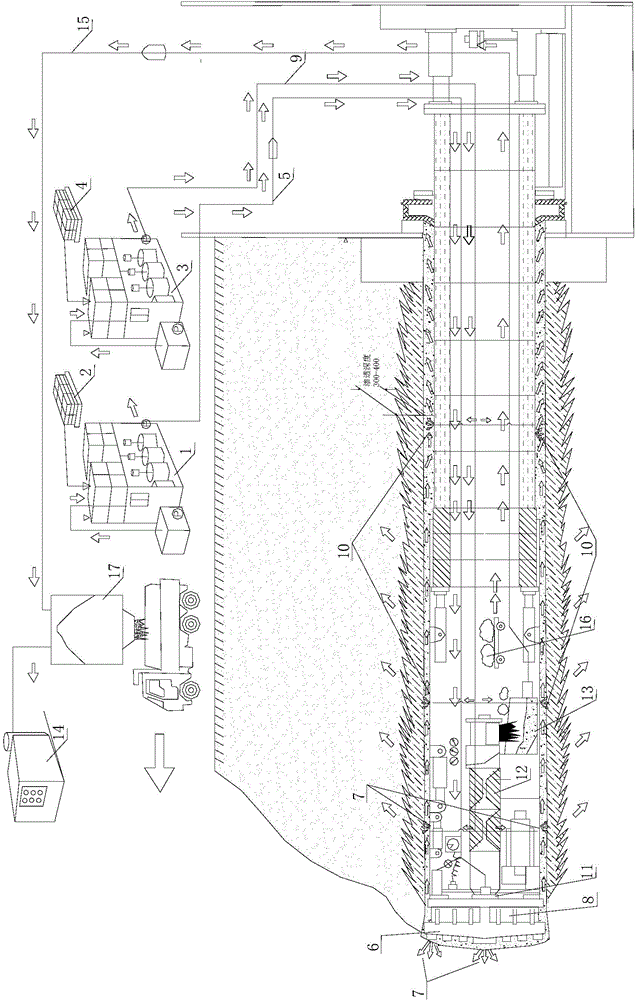

Image

Examples

Embodiment 1

[0028] A mud-thick propulsion method for a shield machine, comprising the following steps:

[0029] 1) Adding powdered clay and tackifier 2 to the mud generating and processing system 1 to prepare thick mud, the powdered clay and tackifier are stirred and mixed to make thick mud with a slump of 18;

[0030] The components of the tackifier include: disodium silicate (CAS No. 15457-97-3), carboxymethyl calcium cellulose (CAS No. 9050-04-8), cross-linked acrylic polymer and sodium salt, wherein : the mass percentage of disodium silicate is 5%, the mass percentage of carboxymethyl calcium cellulose is 3%, the mass percentage of cross-linked acrylic polymer is 2%, the mass percentage of sodium salt is 2.5%; the rest is Water, the specific gravity of the prepared thick mud is 1.3~1.5.

[0031] 2) Make plasticizer A agent and plasticizer B agent in plasticizer generation and processing system 3, and make 100L N solvent with the water of plasticizer A agent 23kg and 82kg; Plasticizer...

Embodiment 2

[0041] A mud-thick propulsion method for a shield machine, comprising the following steps:

[0042] 1) Adding powdered clay and tackifier 2 to the mud generating and processing system 1 to prepare thick mud, the powdered clay and tackifier are stirred and mixed to make thick mud with a slump of 22;

[0043] The components of the tackifier include: disodium silicate (CAS No. 15457-97-3), carboxymethyl calcium cellulose (CAS No. 9050-04-8), cross-linked acrylic polymer and sodium salt, wherein : The mass percentage of disodium silicate is 8%, the mass percentage of carboxymethyl calcium cellulose is 5%, the mass percentage of cross-linked acrylic polymer is 2.5%, the mass percentage of sodium salt is 2.5%; the rest is Water, the specific gravity of the prepared thick mud is 1.3~1.5.

[0044] 2) Make plasticizer A agent and plasticizer B agent in plasticizer generation and processing system 3, and make 100L N solvent with the water of plasticizer A agent 27kg and 85kg; Plasticiz...

Embodiment 3

[0054] A mud-thick propulsion method for a shield machine, comprising the following steps:

[0055] 1) Adding powdered clay and tackifier 2 to the mud generating and processing system 1 to prepare thick mud, the powdered clay and tackifier are stirred and mixed to make thick mud with a slump of 20;

[0056] The components of the tackifier include: disodium silicate (CAS No. 15457-97-3), carboxymethyl calcium cellulose (CAS No. 9050-04-8), cross-linked acrylic polymer and sodium salt, wherein : the mass percentage of disodium silicate is 6%, the mass percentage of carboxymethyl calcium cellulose is 4%, the mass percentage of cross-linked acrylic polymer is 2.2%, the mass percentage of sodium salt is 2.5%; the rest is Water, the specific gravity of the prepared thick mud is 1.3~1.5.

[0057] 2) Make plasticizer A agent and plasticizer B agent in plasticizer generation and processing system 3, and make 100L N solvent with the water of plasticizer A agent 25kg and 83kg; Plasticiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com