Device and method for recycling flue gas waste heat of roasting furnace

A flue gas waste heat recovery device technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of poor heat exchange, condensation on the heat exchange surface, affecting the heat exchange effect, etc., and achieve the effect of reducing waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

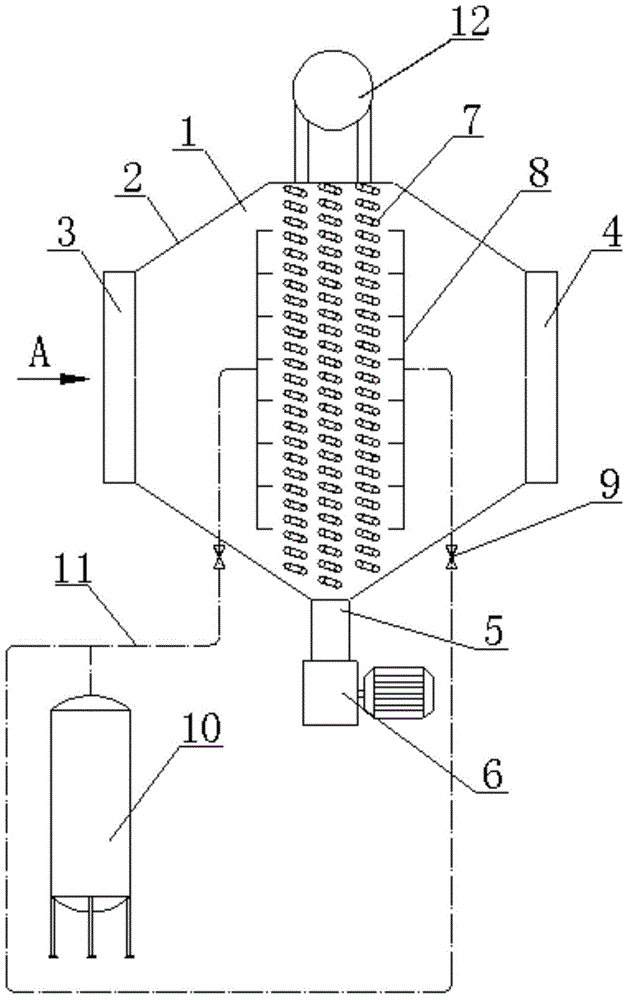

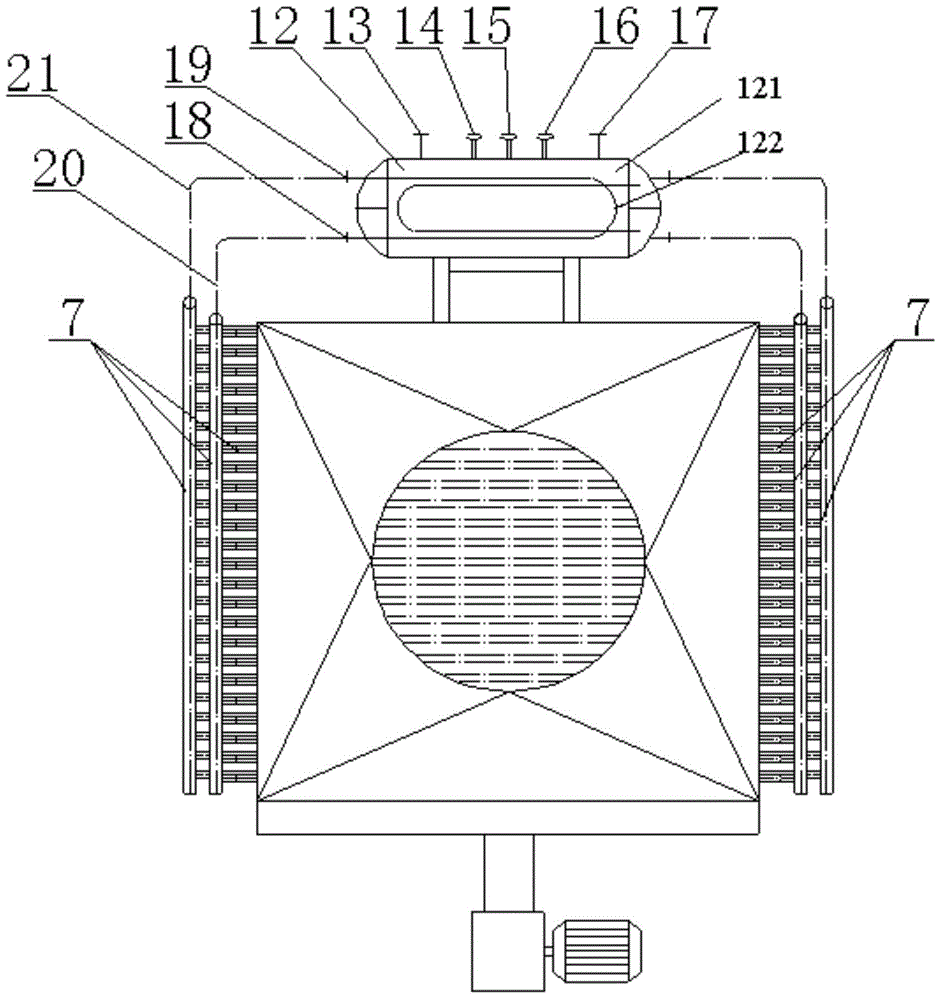

[0025] like figure 1 and figure 2 As shown, the waste heat recovery device for roaster flue gas of the present invention includes a heat exchanger 1 and a steam drum 12 . The heat exchanger 1 includes a shell 2, the two ends of the shell 2 are respectively provided with a flue gas inlet 3 and a flue gas outlet 4, and the middle of the shell 2 is provided with a fin heat exchange tube 7, in this embodiment, the fin heat exchange There are multiple tubes 7, which are arranged horizontally side by side in the shell 2 from top to bottom and fixed on the internal support (not marked), and several rows are discharged at the same time, and the finned heat exchange tubes 7 are evacuated and filled with heat medium The heat medium is more conducive to vaporization in a vacuum state. A compressed air reverse blower 8 is arranged around the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com