A kind of processing method of fermented lotus root tip

A processing method and a lotus root tip technology are applied in the field of processing lotus root tip by using lactic acid bacteria fermentation, which can solve the problems of poor nutritional value and flavor quality, easy browning and softening of lotus root tape, affecting product appearance, etc. Good color and the effect of inhibiting the growth of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The preparation method of Lactobacillus plantarum starter is as follows:

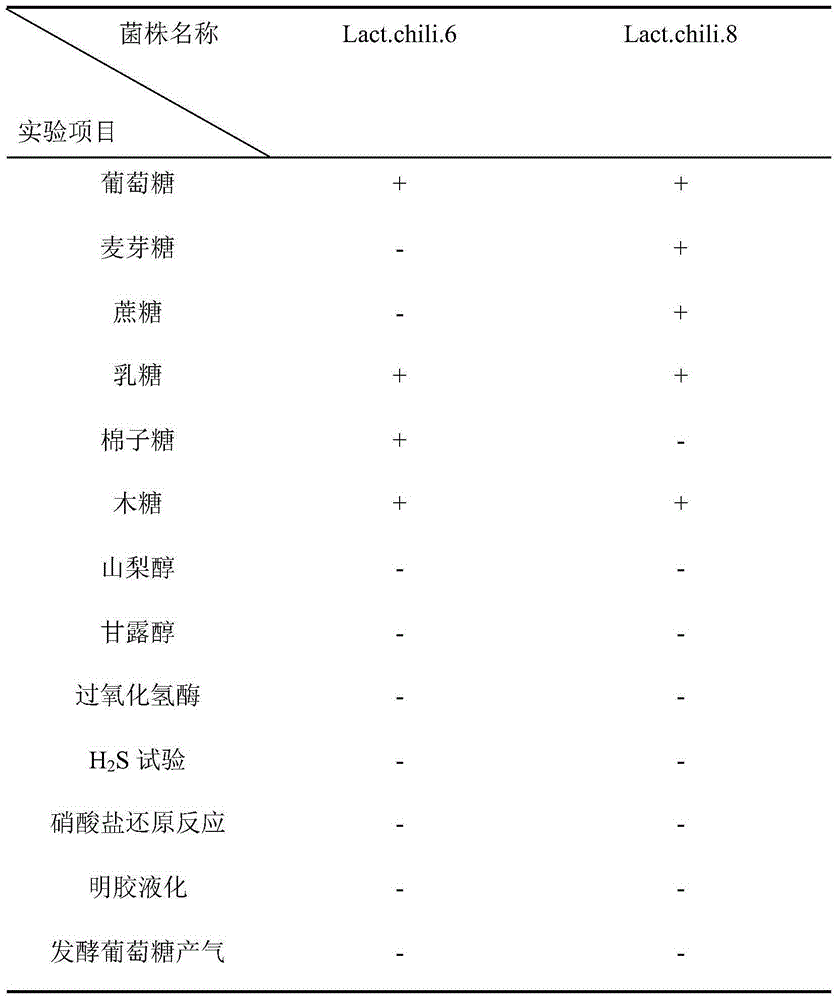

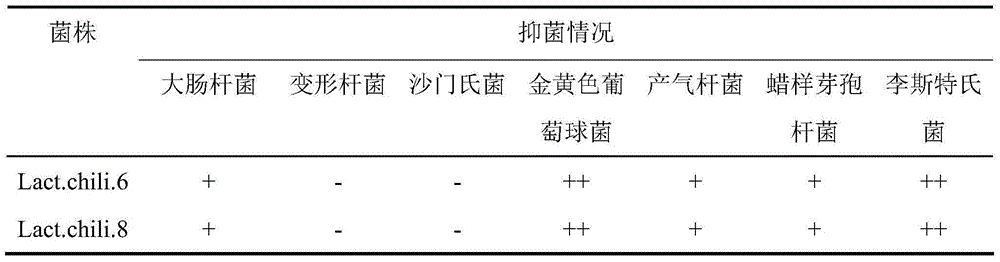

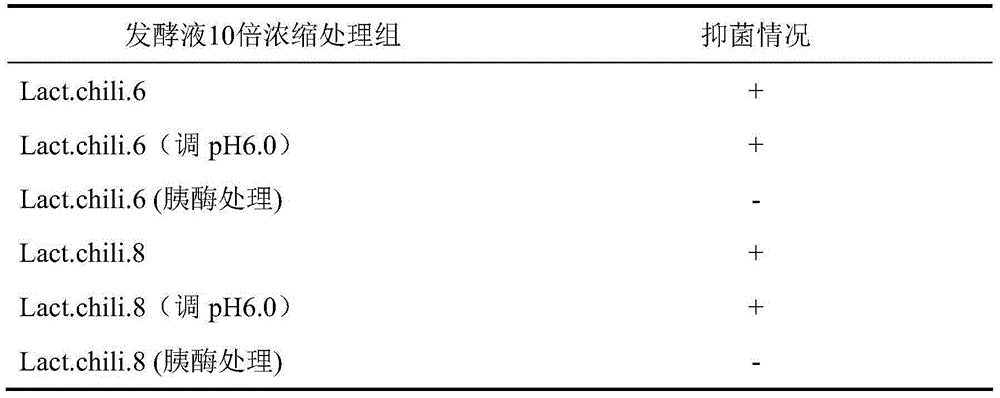

[0051] Lactobacillus plantarum Lact.chili.6 and Lact.chili.8 were respectively inoculated on the slant of MRS solid medium, activated at 37°C for 24h-48h, then transferred to skim milk medium, expanded at 30°C-37°C for 24h ~48h, the control bacteria concentration is 10 9 cfu / ml, and then mix them at a volume ratio of 1:1 to obtain a plantarum lactobacillus starter.

[0052]Picking in the morning and evening and the picking time is no more than 4 hours, fresh and crisp, free of diseases and insect pests, free of rust, floating matter and soil, the fresh lotus root is washed with 0.1% citric acid aqueous solution to remove the tip of the lotus root After removing the rust, floating matter and soil, cut the lotus root into 2cm-long segments, put it in the pool to protect the color and remove the lotus root. The color protection time for the first time is 10 minutes, and the weight ratio of water: ...

Embodiment 2

[0056] The preparation method of plant lactobacillus starter is the same as embodiment 1.

[0057] Picking in the morning and evening and the picking time is no more than 4 hours, fresh and crisp, no pests and diseases, no rust, floating matter and soil as raw materials, and the selected fresh lotus root belts are washed with 0.08% citric acid aqueous solution by weight to remove the lotus tip After removing rust, floating matter and soil, cut the lotus root into 2cm-long segments, and put it in the pool to protect the color and remove the silk. The color protection time for the first time is 15 minutes, and the weight ratio of water: lotus root is about 3:1. Then, use 1‰ citric acid aqueous solution to rinse and desulfurize. , 1.5min, add 0.08% citric acid and 0.15% calcium chloride to the blanching water; the lotus root must be cooled immediately after blanching, and the pH of the cooling water should be controlled to be 4.5-5, and then the lotus root should be packed in a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com