Graphite complex and preparation method thereof

A composite and graphite technology, which is applied in the field of graphite composite and its preparation, can solve problems such as hindering the application of graphite, high production cost, and poor bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] In the preparation method of the present invention, the heating reaction is usually carried out at 600-1500°C (preferably 800-1400°C), and the reaction time is usually 1-120 minutes (preferably 30-90 minutes).

[0045] The invention provides a kind of preparation method of graphite composite body, preferably comprises the steps:

[0046] (1) providing a mixture comprising graphite particles, a carbide forming element and a salt;

[0047] Preferably, based on the total weight of the mixture in step (1), the mass fraction of the salt is 30-80wt%, preferably 50-70wt%.

[0048] Preferably, based on the total weight of the mixture in step (1), the mass fraction of carbide-forming elements is 0.1-10wt%; more preferably, 2-5wt%; more preferably, 3-7.5wt%.

[0049] (2) Under vacuum or in an inert atmosphere (such as nitrogen, helium, etc. or their combination), the mixture in step (1) is subjected to heating reaction (such as reaction at 600-1500 ° C or 800-1300 ° C), Thus, t...

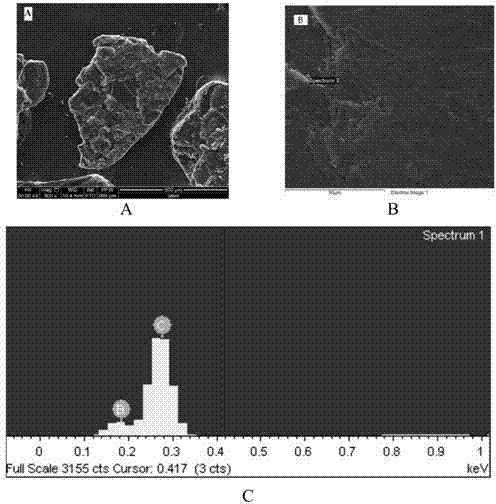

Embodiment 1

[0059] Embodiment 1 graphite-boron carbide-boron complex

[0060] Mix the flaky graphite powder, barium chloride and a small amount of boron powder with a particle size of 30-50 mesh to make a mixed powder. Calculated by the total weight of the mixed powder, sodium chloride accounts for 70wt%, and boron powder accounts for 8wt%. The mixed powder Put it into a vacuum carbon tube furnace and evacuate to a vacuum of about 10 -2 Pa, the heating rate is 15°C / min, the temperature is raised to 1300°C, kept for 90min, and then cooled to room temperature with the furnace.

[0061] Take out the high-temperature-treated mixed powder, put it into a beaker filled with deionized water, put the beaker filled with the treated mixed powder and deionized water into a drying oven, set the temperature at 85°C, keep it warm for 30 minutes, take out the beaker and dry it. Pour off the aqueous solution of sodium chloride, re-pour in deionized water and repeat the above operations, wash the mixed po...

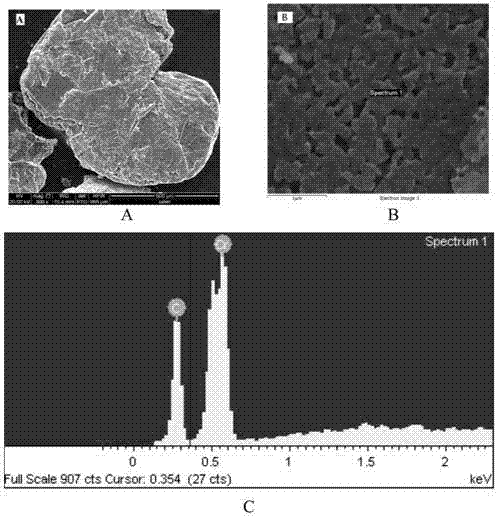

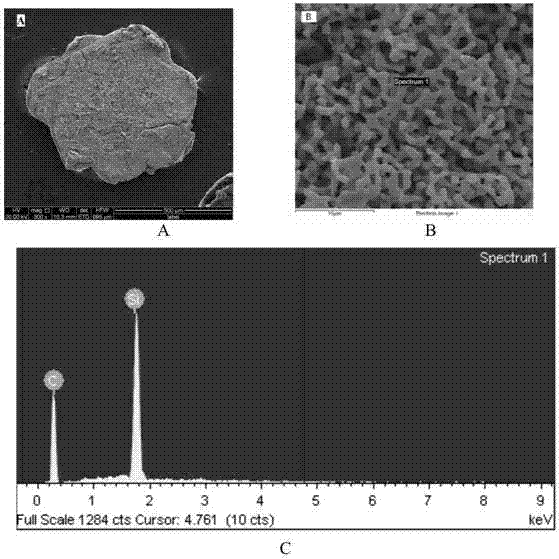

Embodiment 2

[0065] Embodiment 2 graphite-silicon carbide-silicon composite

[0066] Mix the flaky graphite powder, calcium chloride and a small amount of silicon powder with a particle size of 30-50 mesh to make a mixed powder. Calculate the total weight of the mixed powder, sodium chloride accounts for 70wt%, and silicon powder accounts for 8wt%. The mixed powder Put it into a vacuum carbon tube furnace and evacuate to a vacuum of about 10 -2 Pa, the heating rate is 15°C / min, the temperature is raised to 1300°C, kept for 90min, and then cooled to room temperature with the furnace.

[0067] Take out the high-temperature-treated mixed powder, put it into a beaker filled with deionized water, put the beaker filled with the treated mixed powder and deionized water into a drying oven, set the temperature at 85°C, keep it warm for 30 minutes, take out the beaker and dry it. Pour off the aqueous solution of sodium chloride, re-pour in deionized water and repeat the above operations, wash the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com