Flame retardant carbon-forming agent poly(terephthalate) dimethic acid polymer and preparation method thereof

A technology of dimethyl silicic acid and phenylene diester, which is applied in the field of silicon-based flame-retardant char-forming agent polydimethylsilicate terephthalate polymer and its preparation, can solve the problems of poor processing performance, low decomposition temperature, Easy to absorb water and other problems, to achieve the effect of excellent flame retardant effect, high decomposition temperature and low volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

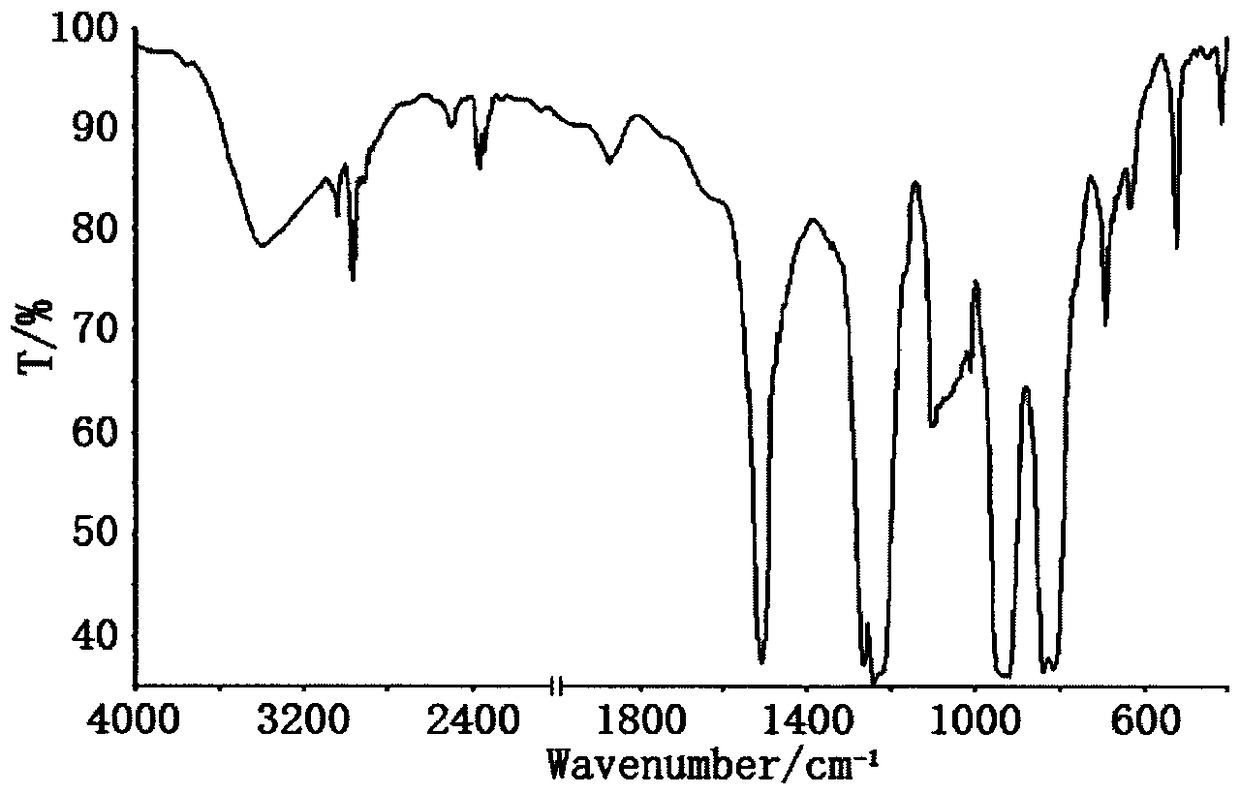

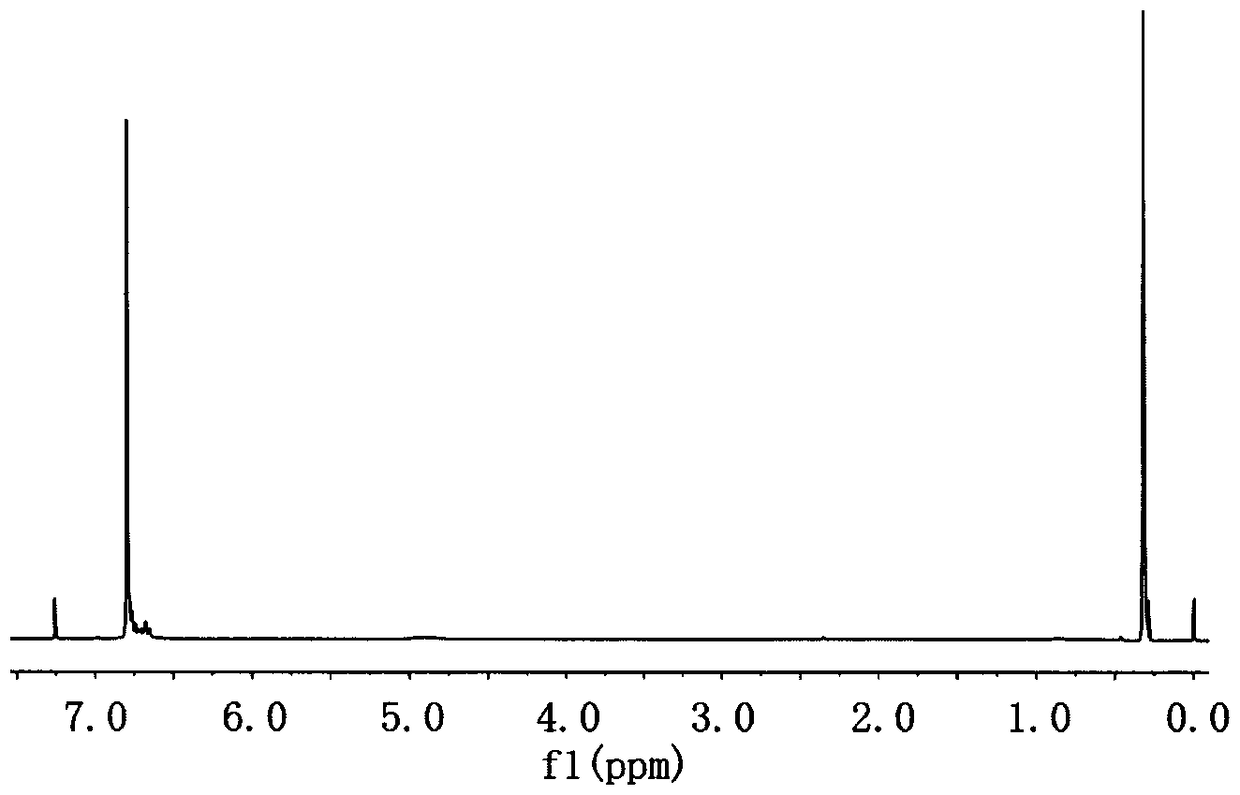

[0040] Example 1 In a 250ml four-necked bottle equipped with a stirrer, a thermometer and a condenser tube, and a drying tube on the top of the condenser tube, replace the air in the bottle with nitrogen, and add 5.50g (0.05mol) of terephthalate Phenol, 80ml dichloroethane and 10.1g (0.1mol) triethylamine, dropwise add 6.45g (0.05mol) dimethyl dichlorosilane, control the reaction temperature with the rate of addition not higher than 40 ℃, be warmed up to 65°C, keep warm for 9 hours; then add 0.08g of methanol dropwise as an end-capping agent, keep warm for 0.5h; cool down to below 30°C, then add 30ml of distilled water to wash twice, separate the liquids, and wash the obtained dichloroethane layer with 4g Dry it with anhydrous sodium sulfate, filter it with suction, and distill off the filtrate under reduced pressure to remove dichloroethane to obtain polydimethylsilicate terephthalate with a yield of 92.7%.

Embodiment 2

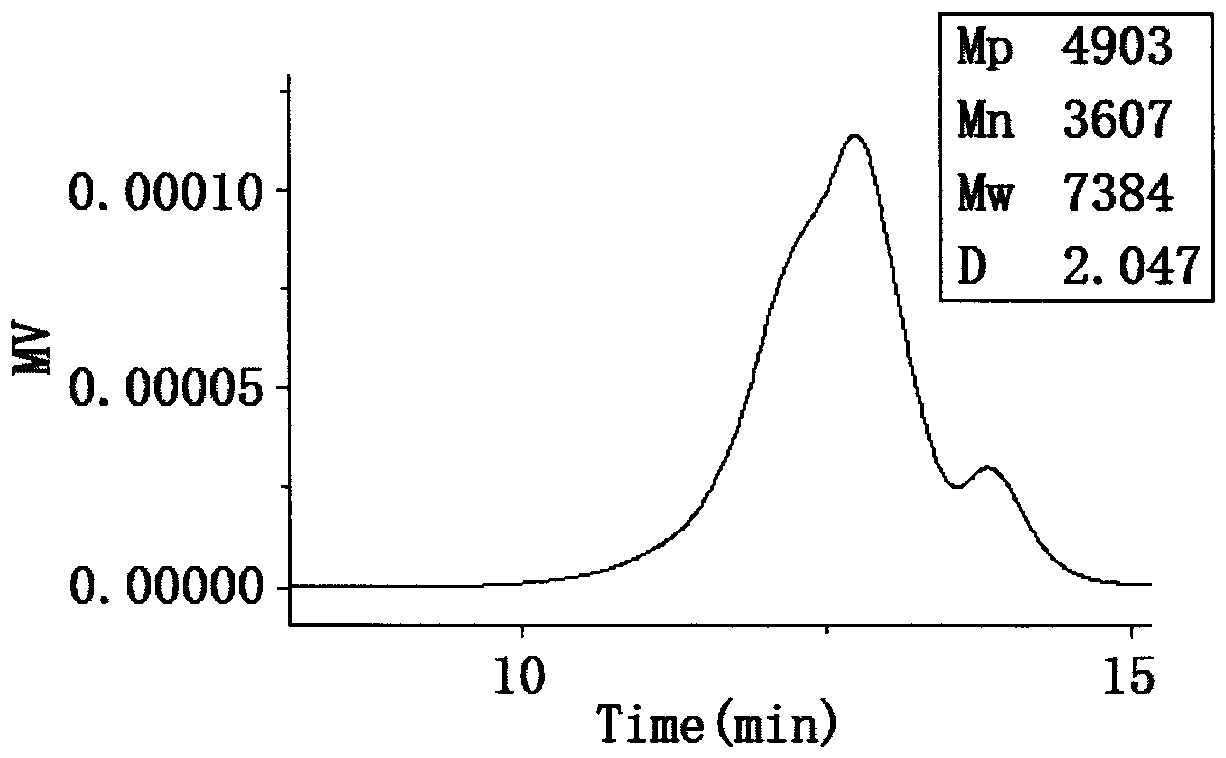

[0041]Example 2 In a 250ml four-neck bottle equipped with a stirrer, a thermometer and a condenser tube, and a drying tube on the top of the condenser tube, replace the air in the bottle with nitrogen, and add 5.50 g (0.05 mol) of terephthalic acid Phenol, 110ml toluene and 12.63g (0.125mol) triethylamine, add dropwise 6.45g (0.05mol) dimethyl dichlorosilane, control the reaction temperature with the rate of addition not higher than 40°C, and raise the temperature to 70°C after dropping, Heat preservation reaction for 7 hours; then add 0.08g of methanol dropwise as an end-capping agent, heat preservation reaction for 0.5h; lower the temperature to below 30°C, then add 30ml of distilled water to wash twice, separate the liquid, and dry the obtained toluene layer with 6g of anhydrous magnesium sulfate , suction filtration, and the filtrate was distilled under reduced pressure to remove toluene to obtain polydimethylsilicate terephthalate, yield: 93.5%, weight average molecular we...

Embodiment 3

[0042] Example 3 In a 250ml four-necked bottle equipped with a stirrer, a thermometer and a condenser tube, and a drying tube on the top of the condenser tube, replace the air in the bottle with nitrogen, and add 5.50 g (0.05 mol) of terephthalic acid Phenol, 80ml xylene and 11.11g (0.11mol) triethylamine, add dropwise 6.45g (0.05mol) dimethyldichlorosilane, control the reaction temperature with the dropping rate not higher than 40°C, and raise the temperature to 50°C after dropping , heat preservation reaction for 12 hours; then add 0.08g of methanol dropwise as an end-capping agent, heat preservation reaction for 0.5h; lower the temperature to below 30°C, then add 50ml of distilled water to wash twice, separate the liquid, and wash the obtained xylene layer with 8g of anhydrous sodium sulfate After drying and suction filtration, the filtrate was distilled off under reduced pressure to remove xylene to obtain polydimethylsilicate terephthalate with a yield of 91.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com