Synergistic hybrid textile waste rubber-based damping vibration-absorbing composite material and its manufacturing method

A composite material and rubber-based technology, which is applied in the field of engineering materials, can solve problems such as waste smoke, waste gas emissions, and environmental pollution, and achieve the effects of protecting the ecological environment, simple operation, and good economic and social value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The mass percentage of each component of the synergistic hybrid textile waste rubber-based damping vibration reduction composite material adopts TWRP:AO 2246:AO4426=70:30:0, and the preparation steps of the composite material are as follows:

[0033] The first step of mixing:

[0034] 1> Raise the temperature of the rollers on the double-roller plastic refining machine to 60°C and keep it basically stable;

[0035] 2>Add textile waste rubber powder (TWRP) between the rollers to form a film through the surface temperature of the rollers and the shearing action between the double rollers;

[0036] 3> After weighing the film-forming TWRP and AO 2246 according to the mass ratio of 70:30, first mix the TWRP film between the double rollers, then slowly add AO 2246, and use a cutter as an auxiliary mixing to make the components well mixed;

[0037] 4> The total mixing time is 40 minutes. After mixing evenly, the mixed material is peeled off from the roller and cooled at room...

Embodiment 2

[0044] The first step of mixing:

[0045] 1> Raise the temperature of the rollers on the double-roller plastic refining machine to 65°C and keep it basically stable;

[0046] 2> After weighing the material of Example 1 and AO 4426 according to the mass ratio of 90.9:9.1 (that is, TWRP:AO2246:AO 4426=63.6:27.3:9.1), the TWRP / AO 2246 (70 / 30) film Mix between the double rollers, then slowly add AO 4426, use a cutter as an auxiliary mixing to make the components evenly mixed;

[0047] 3> the total mixing time is 60 minutes (adding the total time of the material prepared in Example 1), after mixing evenly, the mixing material is peeled off from the roller, and cooled at room temperature to prepare for heating For pressing and forming.

[0048] The second step of thermoforming:

[0049] 1> Cut the cooled kneaded film into a size slightly larger than the inner cavity of the mold and lay it in the mold cavity. Mucous membranes are isolated;

[0050] 2> Move the steel plate into the...

Embodiment 3

[0054] The mass percentage of each component of the textile waste rubber-based damping and vibration-reduction composite material of synergistic hybridization adopts TWRP:AO 2246:AO4426=70:30:30=53.8:23.1:23.1, and the preparation steps of the composite material are the same as in Example 2, Its process is different from Example 2 in that the temperature is 70° C. when the raw materials are uniformly mixed on the double-roller plastic extruder, and the time is 80 minutes (plus the total time of preparing the material in Example 1). The sample was hot-pressed under a flat vulcanizing machine at a temperature of 165°C. The preheating time was 30 minutes without pressure, and the hot-pressing time was also 40 minutes. The pressure was 16Mpa. Finally, the material was taken out and cooled in ice water. Thus, a synergistic hybrid textile waste rubber-based damping composite material C with a thickness of 1 mm was prepared.

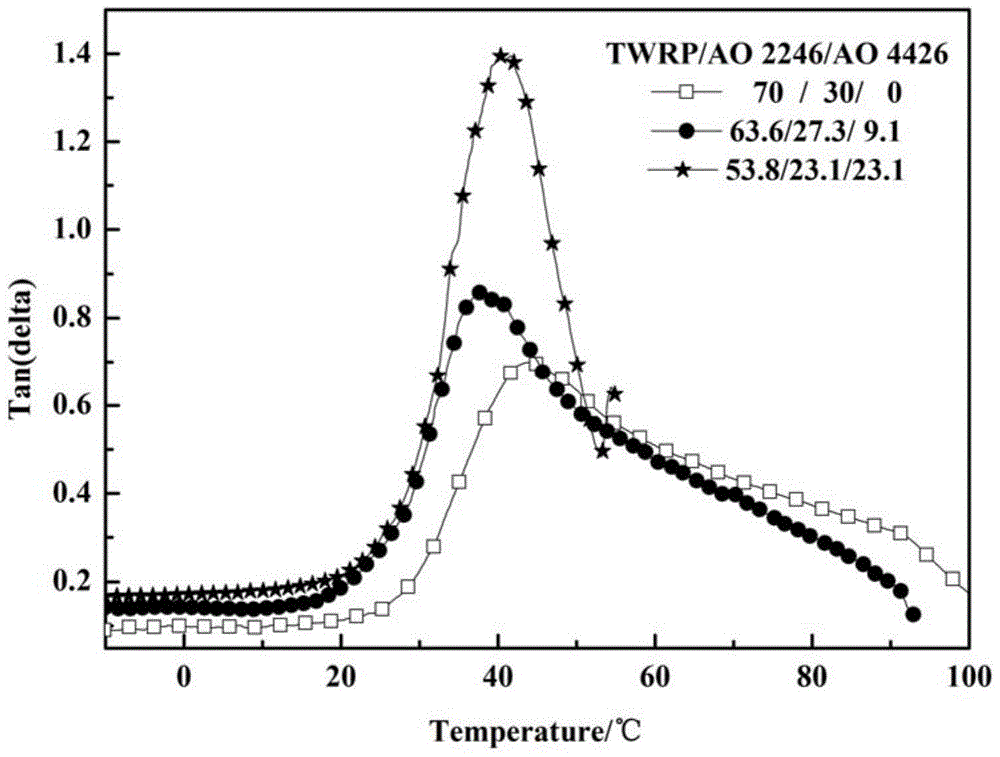

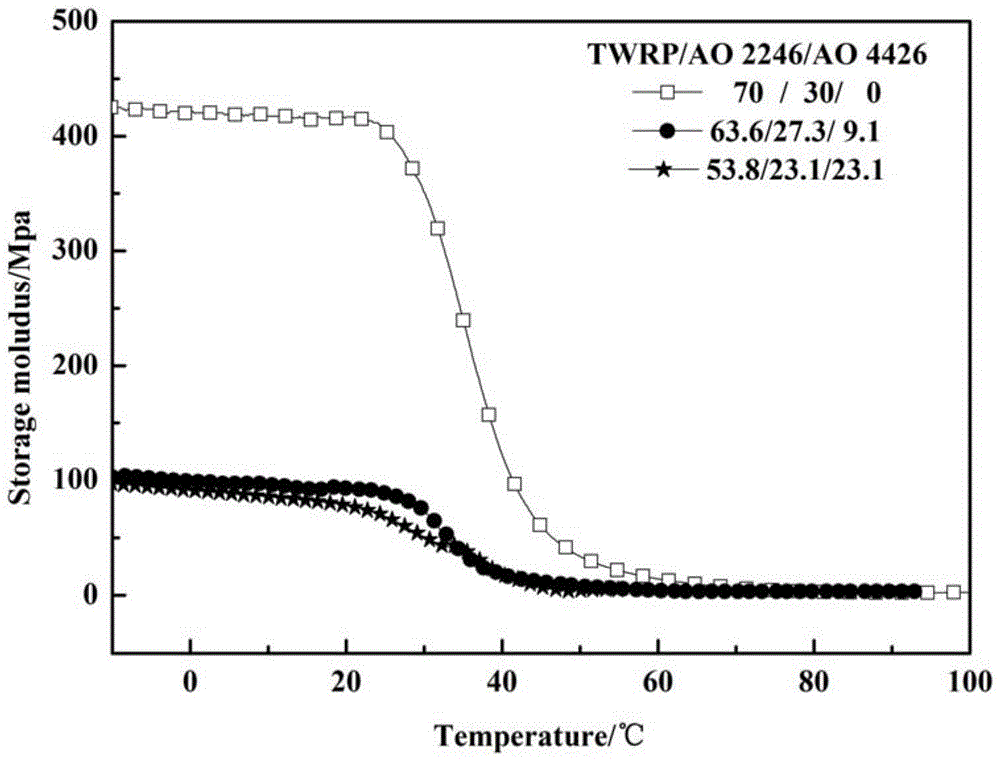

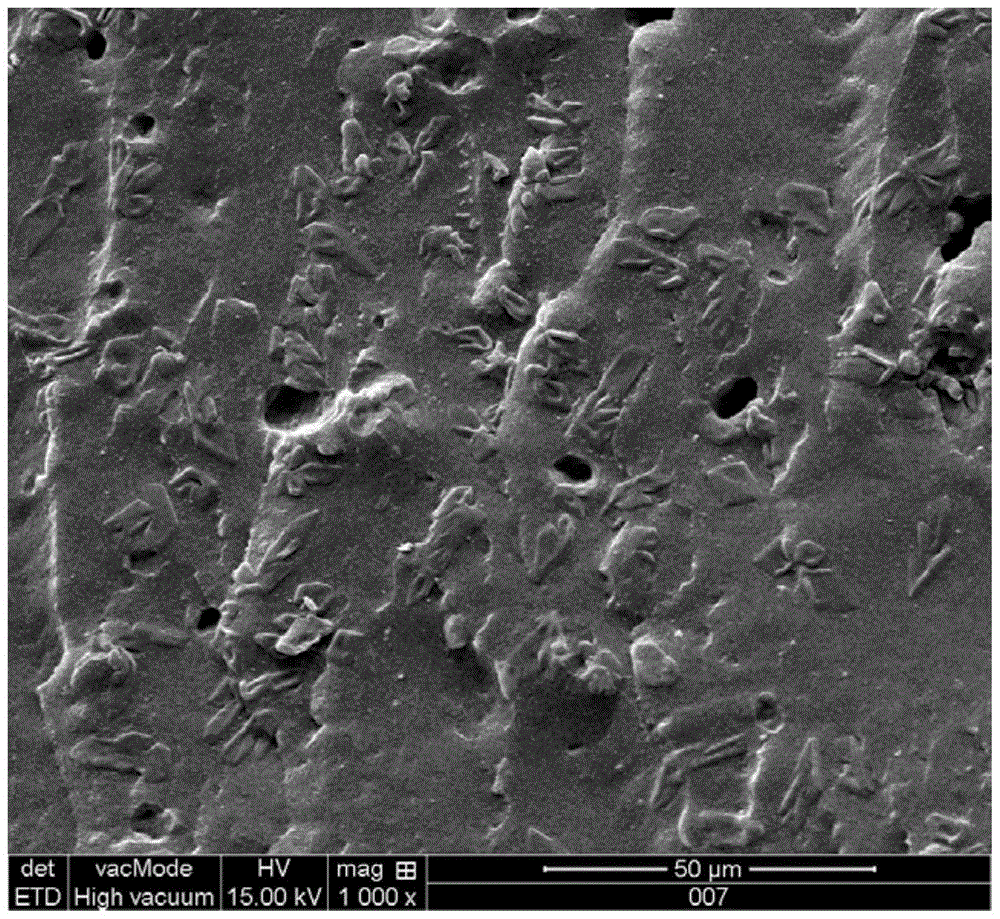

[0055] It was placed in liquid nitrogen for brittle fract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com