A method and device for preparing a wear-resistant coating based on laser shock wave technology

A wear-resistant coating, shock wave technology, applied in the field of parts remanufacturing, to achieve high density, improve the ability to resist shock loads, reduce friction coefficient and wear rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

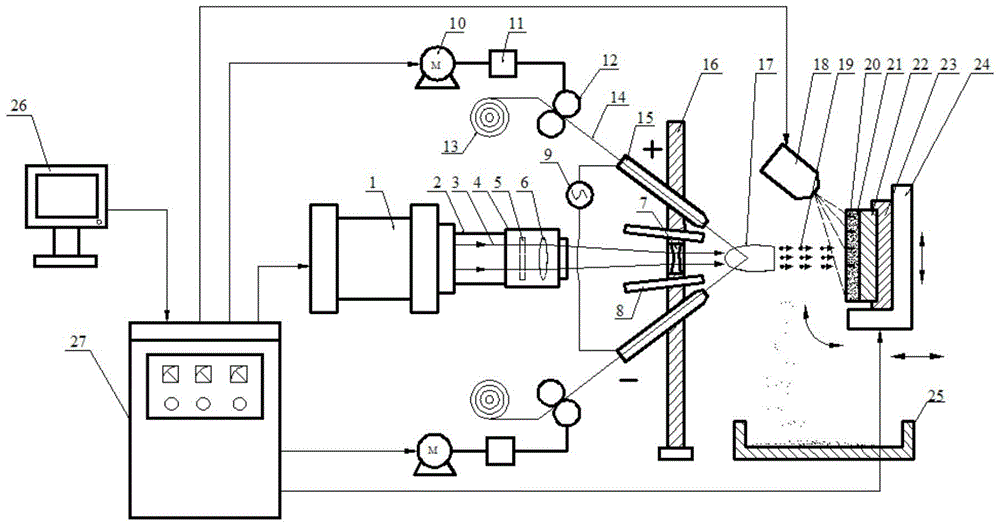

[0029] This embodiment provides a preparation method and device for embedding Al particles into a WC—Co hard material coating driven by laser shock waves.

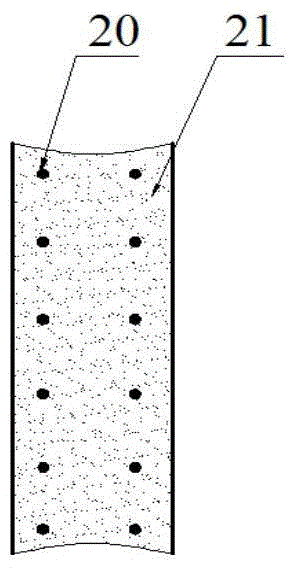

[0030] The inventive device includes a laser generator 1, a light guiding and splitting system, an arc liquid making system, a workpiece fixture system, and a control system. The light guide and split system includes light guide tube 2, main laser pulse beam 3, impact head 4, optical template 5, convex lens 6, concave lens 7 and side plate 16; the arc liquid making system includes intake pipe 8, power supply 9, motor 10, Reducer 11, roller 12, wire reel 13, metal spraying wire 14, electrode 15, side plate 16; workpiece fixture system includes plasma spray gun 18, workpiece 22, fixture 23, five-axis worktable 24 and recovery tank 25; control system includes computer 26 and controller 27.

[0031] Before spraying, degrease, sandblast, clean and preheat the workpiece 22, then use WC-Co powder as raw material, use plasma spra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com