Method for detecting surface oxidized scale sample of hot rolled steel plate

A hot-rolled steel plate and surface oxidation technology, which is applied in the field of backscattered image analysis, can solve the problems of unclear imaging effect of light microscope, inability to corrode, and easily broken oxide scale, so as to achieve clear structure and tissue pictures, avoid extrusion deformation or The effect of shedding and excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1. Heat the sample Fe-Cr alloy to 1100°C, keep it warm for 2 hours, and then cool it to room temperature with the furnace, and then use the wire cutting method to cut a section on the hot-rolled strip steel, with a length of 8mm, a width of 10mm, and a thickness of 2.2mm. Acetone is the cleaning solution to remove surface oil;

[0045] 2. Take a PVC pipe with a diameter of 15mm, and use a cutter to cut a section with a length of 12mm;

[0046] 3. Cut a piece of oil paper of 30×30mm, seal the oil paper on one side of the PVC pipe with solid glue; then weigh the liquid epoxy resin and curing agent in proportion, pour it into a beaker, stir it evenly with a glass rod, and place it at an angle 25min, until the bubbles in the medium disappear;

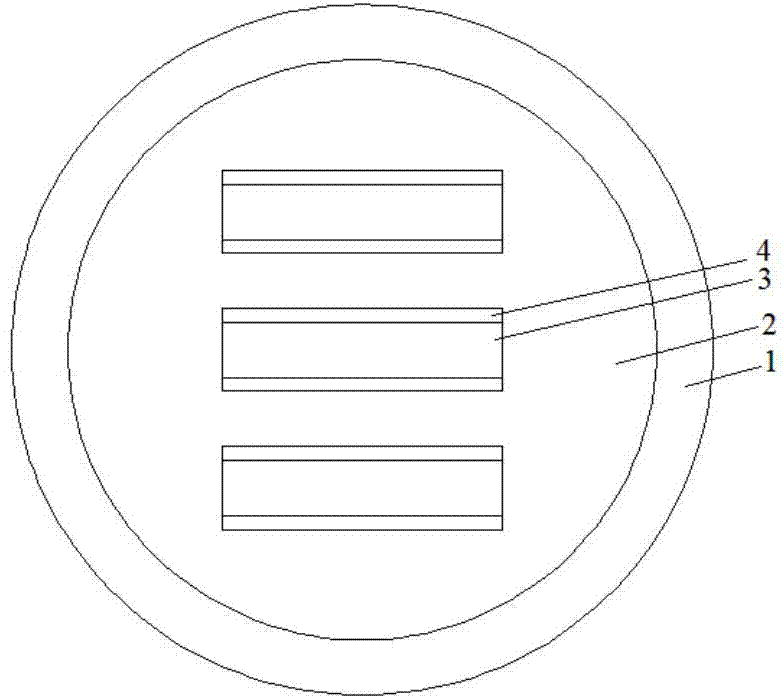

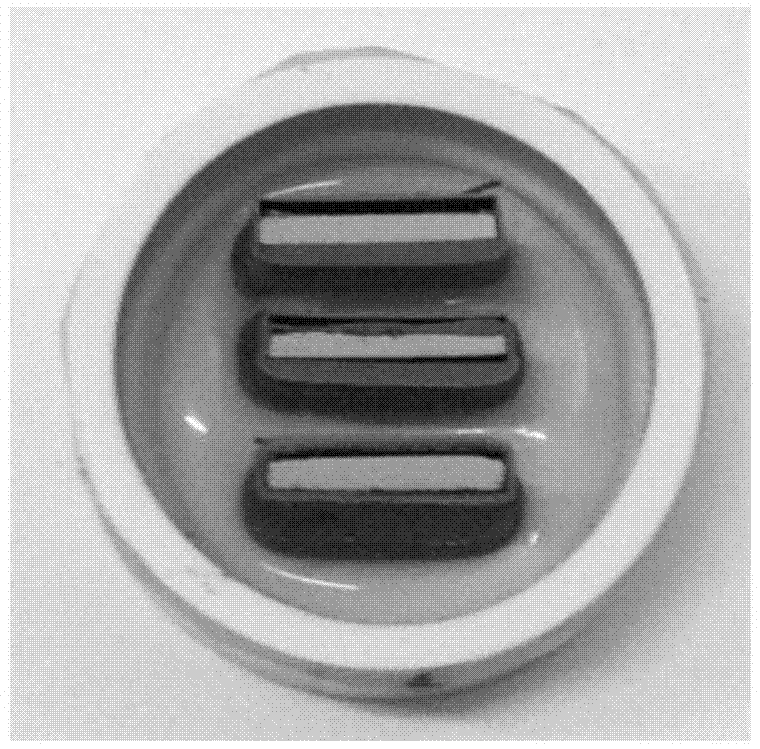

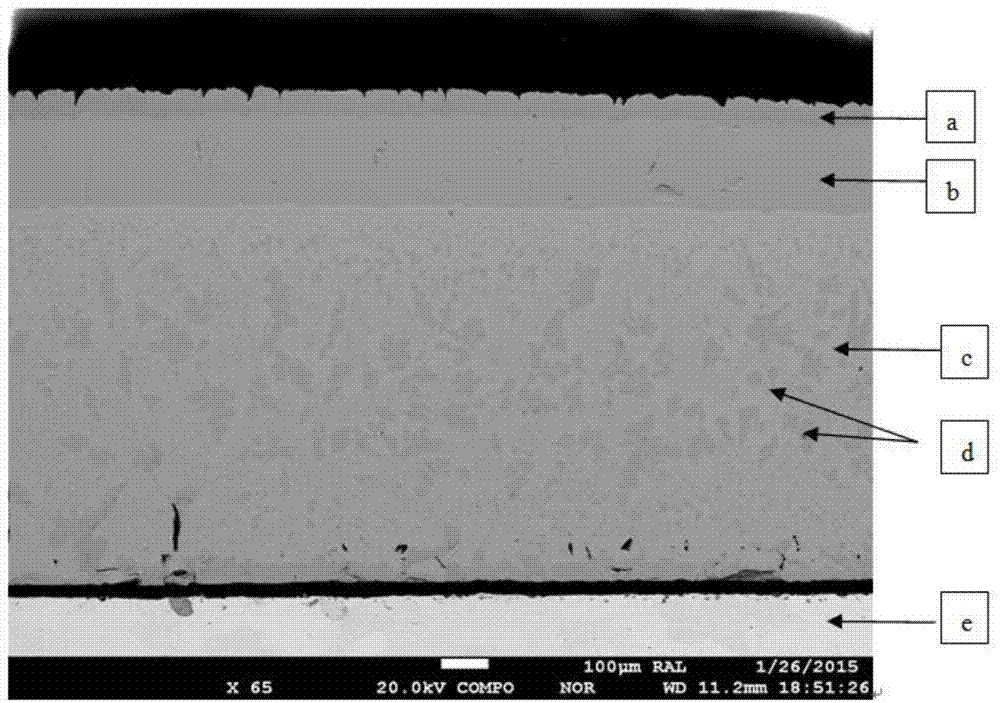

[0047]Put the sample vertically into the tube, so that one long side of the sample is in contact with the sealing surface, and the other long side faces outward, such as figure 1 and figure 2 As shown, the cross-section of the sa...

Embodiment 2

[0055] 1. Heat the sample Fe-Cr alloy to 800°C, keep it warm for 2 hours, and then cool it to room temperature with the furnace; use the wire cutting method to cut a section on the hot-rolled strip steel, with a length of 11mm, a width of 8mm, and a thickness of 2.3mm. Remove surface oil for cleaning fluid;

[0056] 2. Take a PE pipe with a diameter of 20mm, and use a cutter to cut a section with a length of 13mm;

[0057] 3. Cut a piece of oil paper, seal the oil paper on one side of the PE pipe with solid glue; weigh the liquid epoxy resin and curing agent in proportion, pour it into a beaker, stir it evenly with a glass rod, and place it at an angle for 10-30 minutes , until the bubbles in the medium disappear;

[0058] Put the sample vertically into the pipe, so that one long side of the sample is in contact with the sealing surface, and the other long side faces outward; use a glass rod to dip in the epoxy resin medium, drop it into the PE pipe along the pipe wall, and t...

Embodiment 3

[0066] 1. Heat the sample Fe-Cr alloy to 900°C, keep it warm for 2 hours, and then cool it to room temperature with the furnace; use the wire cutting method to cut a section on the hot-rolled strip steel, with a length of 10mm, a width of 12mm, and a thickness of 2.35mm. Remove surface oil for cleaning fluid;

[0067] 2. Take a PPR pipe with a diameter of 15mm, and use a cutter to cut a section with a length of 12mm;

[0068] 3. Cut a piece of oil paper, seal the oil paper on one side of the PPR tube with solid glue; weigh the liquid epoxy resin and curing agent in proportion, pour it into a beaker, stir it evenly with a glass rod, and place it at an angle for 10-30 minutes , until the bubbles in the medium disappear;

[0069] Put the sample vertically into the pipe, so that one long side of the sample is in contact with the sealing surface, and the other long side faces outward; use a glass rod to dip in the epoxy resin medium, drop it into the PPR tube from the tube wall, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com