Fringe-field switching mode thin film transistor array substrate and manufacturing method thereof

A thin-film transistor and fringe field switching technology, which is applied in the manufacture of semiconductor/solid-state devices, electric solid-state devices, semiconductor devices, etc., can solve the problems of rapid release of ionic impurities, residual ionic impurities, and residual ions, etc. Achieve the effect of enhancing fringe electric field, improving afterimage problem and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention provide a fringe field switching mode thin film transistor array substrate and a manufacturing method thereof, which are beneficial to enhancing the fringe electric field, reducing the driving voltage of liquid crystal molecules, thereby reducing power consumption, and effectively improving afterimage problems during display. Each will be described in detail below.

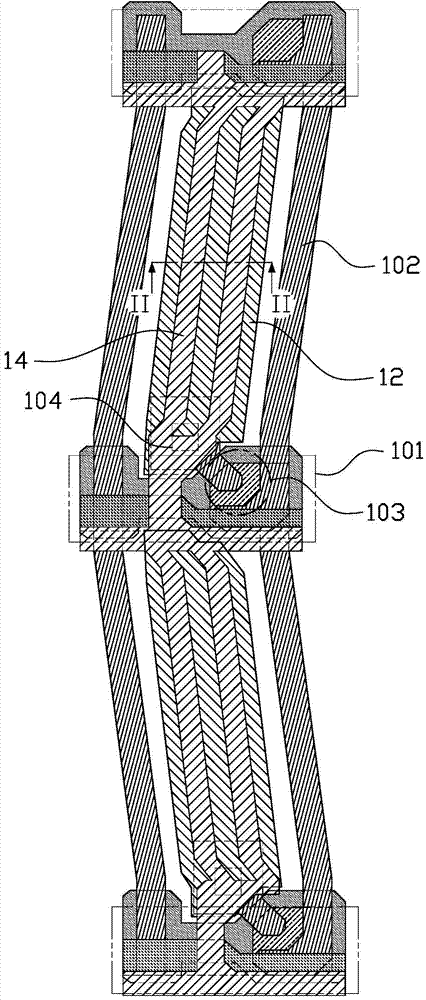

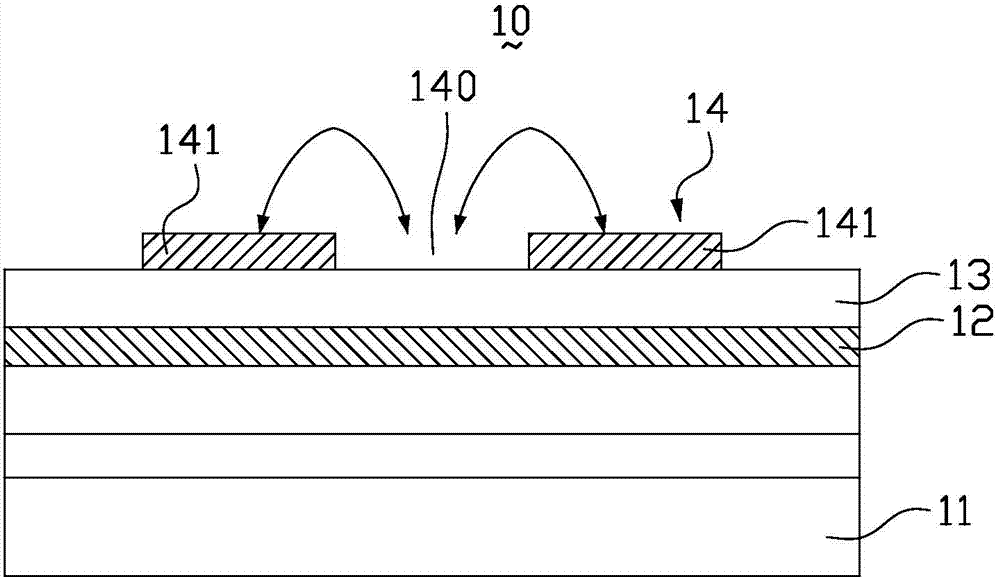

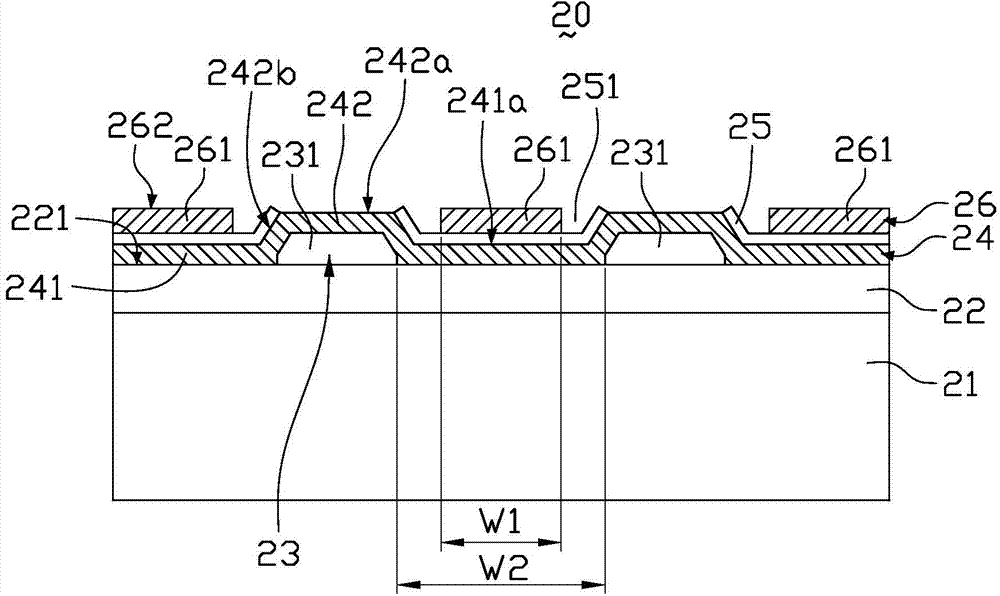

[0030] image 3 is a partial cross-sectional schematic diagram of a thin film transistor array substrate in fringe field switching mode according to the first embodiment of the present invention, please refer to image 3 The thin film transistor array substrate 20 in fringe field switching mode provided in the first embodiment includes a transparent substrate 21 and a plurality of scanning lines 101 formed on the transparent substrate 21 ( figure 1 ) and multiple data lines 102 ( figure 1), a plurality of scanning lines 101 and a plurality of data lines 102 intersect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com