Preparation method of bamboo biochar

A biochar and product technology, applied in the field of biochar preparation, can solve the problems of environmental pollution and inability to be fully utilized, and achieve the effect of increasing economic benefits, improving utilization rate and added value, and having broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

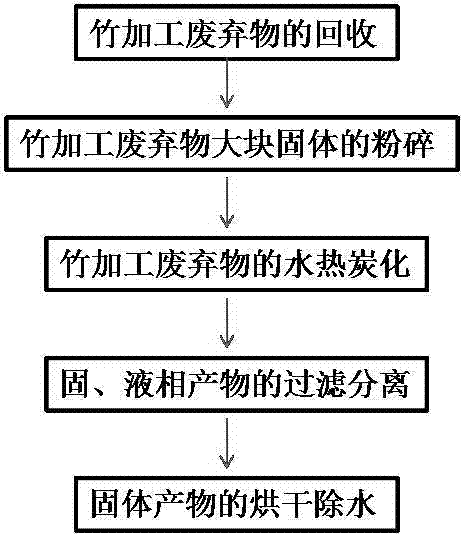

[0023] Embodiments of the present invention provide a kind of preparation method of bamboo biochar, comprising the following steps:

[0024] The bamboo raw material is crushed, mixed with water, and then introduced into a hydrothermal reaction kettle for hydrothermal carbonization reaction. The ratio of the mass of the bamboo raw material to the volume of water is 1kg:6L~1kg:22L; the product of the hydrothermal carbonization reaction is cooled , separated by filtration, and dried to obtain bamboo biochar.

[0025] In the above technical solution, the present invention realizes the comprehensive utilization of bamboo materials, increases the added value, and can fix carbon and reduce emissions, and obtains products that can be used for environmental pollution restoration, and has good economic and social benefits.

[0026] As a preferred solution, the present invention also includes a pretreatment step of bamboo raw materials: reclaiming waste bamboo leaves, bamboo powder, bamb...

Embodiment 1

[0036] Such as figure 1 Shown, bamboo biochar is prepared according to the following steps:

[0037] Step 1. Recycling and pretreatment of bamboo raw materials: Recycling waste bamboo leaves, bamboo powder, bamboo stalk residues or other bamboo processing wastes generated during bamboo processing, and removing soil and debris on the surface of raw materials;

[0038] Step 2, crushing of bamboo raw materials: crushing bamboo raw materials to obtain small particles, storing them for subsequent use;

[0039] Step 3. Hydrothermal carbonization of bamboo raw materials: Mix bamboo particles with water, import them into a hydrothermal kettle, ensure that the hydrothermal kettle is airtight, and heat for hydrothermal carbonization reaction. The hydrothermal reaction temperature is 160 o C, reaction time 15 h, bamboo raw material and water-solid-liquid ratio 1kg:6L;

[0040] Step 4. Filtration and separation of solid and liquid phase products: After the hydrothermal carbonization pro...

Embodiment 2

[0043] Step 1. Recycling and pretreatment of bamboo raw materials: Recycling waste bamboo leaves, bamboo powder, bamboo stalk residues or other bamboo processing wastes generated during bamboo processing, and removing soil and debris on the surface of raw materials;

[0044] Step 2, crushing of bamboo raw materials: crushing bamboo raw materials to obtain small particles, storing them for subsequent use;

[0045] Step 3. Hydrothermal carbonization of bamboo raw materials: mix bamboo particles with water, introduce them into a hydrothermal kettle, ensure that the hydrothermal kettle is airtight, and heat for hydrothermal carbonization reaction. The hydrothermal reaction temperature is 200 o C, reaction time 3 h, bamboo raw material and water-solid-liquid ratio 1kg:6L;

[0046] Step 4. Filtration and separation of solid and liquid phase products: After the hydrothermal carbonization process, take out the hydrothermal reaction kettle and place it in cooling water, and cool it to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com