Reverse osmosis water treatment system and water treatment method

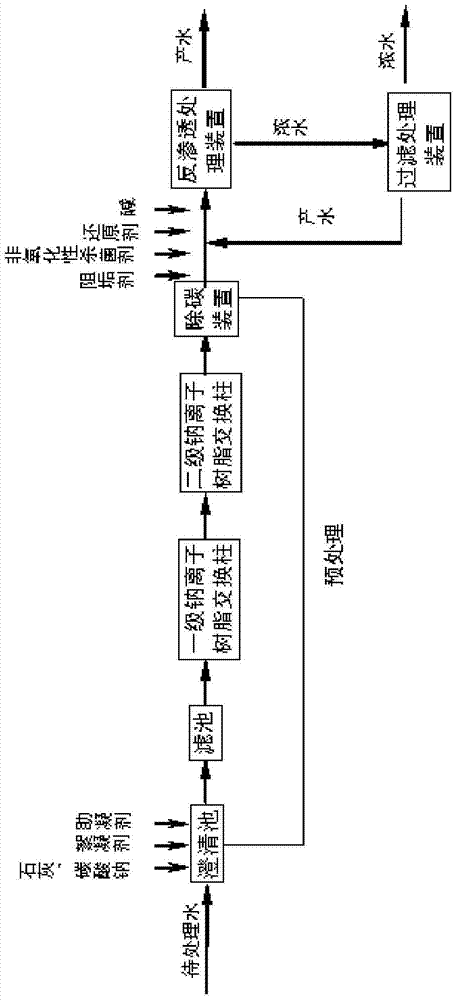

A water treatment system, reverse osmosis water technology, applied in the direction of osmosis/dialysis water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. Reduced recovery rate, reduced system economy, etc., to achieve the effect of saving water treatment costs, reducing energy consumption, and reducing processing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1 Water treatment of sewage in a chemical industrial park

[0050] After sampling and analysis, the quality conditions of influent water to be treated are as follows:

[0051] Table 1

[0052] project

unit

analysis results

pH

7.42

NTU

0.9

mg / L

≤4(not detected)

COD cr

mg / L

96

NH 3 -N

mg / L

186.7

K +

mg / L

120.0

Na +

mg / L

1900.2

Mg 2+

mg / L

22.8

Ca 2+

mg / L

217.6

[0053] CO 3 2-

mg / L

3.4

HCO 3 2-

mg / L

584.0

NO 3 -

mg / L

50.0

Cl -

mg / L

2848.9

F -

mg / L

1.0

SO 4 2-

mg / L

1000.4

All silicon (SiO 2 count)

mg / L

11.7

dissolved solids

mg / L

7000.2

[0054] The reagents or medicaments used are shown in the table below:

[0055] Table 2 ...

Embodiment 2

[0069] Example 2 Water treatment of sewage in a chemical industrial park

[0070]The water treatment process flow is basically the same as in Example 1, except that the nanofiltration device is replaced by an electro-adsorption desalination device. Among them, the positive and negative electrode plates used in the electro-adsorption desalination device are activated carbon electro-adsorption plates, including one 50 pairs of 1800mm×300mm×2.5mm electro-adsorption modules, and the applied voltage is 1.2-2V.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com