Method for recycling treatment of rinsing solution during production of bleaching powder concentrate

A technology of production process and treatment method, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. , to achieve the effect of strong operability, short processing time and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

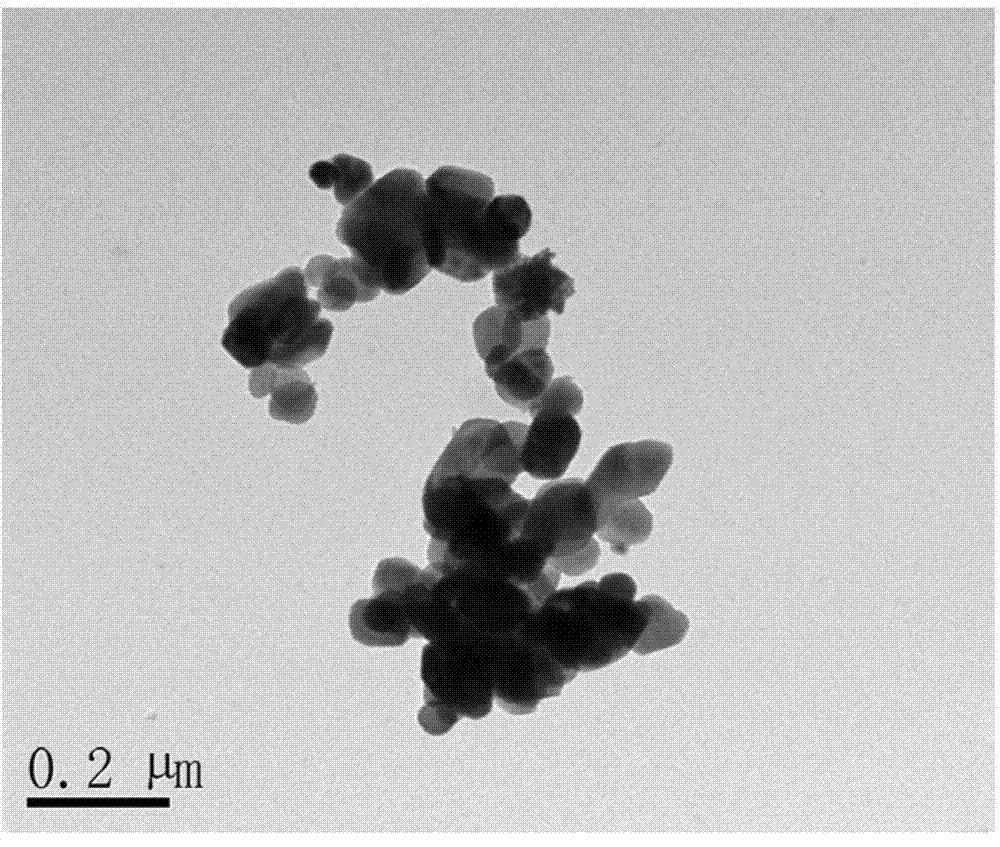

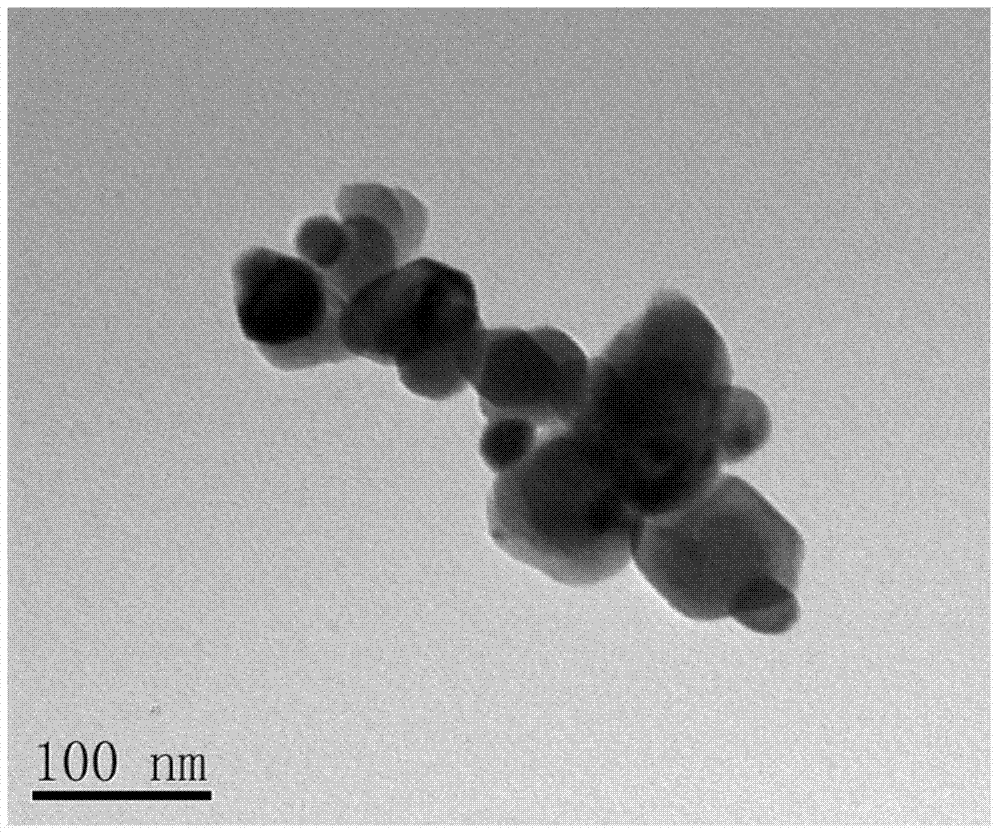

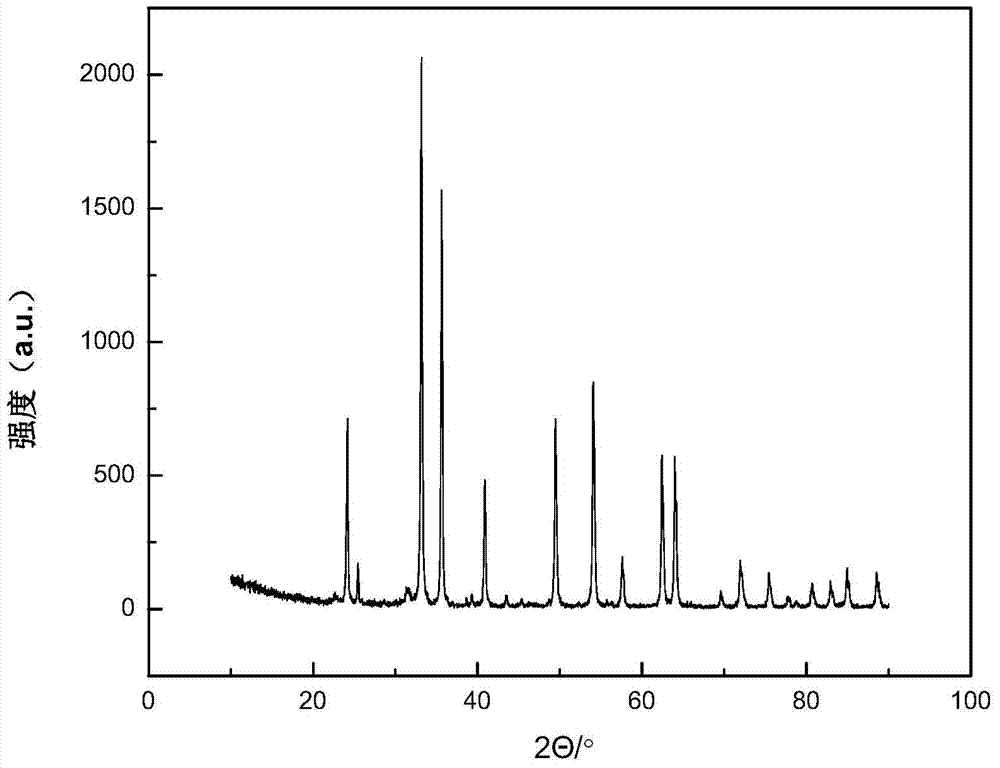

Image

Examples

Embodiment 1

[0025] The method for recycling the rinse solution in the production process of bleaching powder includes the following steps:

[0026] (1) At a temperature of 25-30°C and under stirring conditions, add 5ml of pickling solution to a container containing 50ml (55.35g) of rinse solution to make the pH = 4, stir evenly, and obtain an orange-red viscous shape substance;

[0027] (2) Under the condition of stirring, add 13.5ml pickling solution to make the orange-red viscous substance turn into black liquid;

[0028] (3) Under the condition of stirring, add 200ml rinse solution, make pH=7, the black liquid gradually becomes the liquid containing orange-red particles and chlorine gas is generated, continue to stir for 10min; collect chlorine gas; chlorine gas can be prepared into polymer by conventional technology Ferric chloride products;

[0029] (4) Filter the liquid containing orange-red particles obtained in step (3) to obtain a colorless, clear and transparent neutral liquid...

Embodiment 2

[0032] The method for recycling the rinse solution in the production process of bleaching powder includes the following steps:

[0033] (1) At a temperature of 25-30°C and under stirring conditions, add 4ml of pickling solution to a container containing 50ml (55.35g) of rinse solution to make the pH = 5, stir evenly, and obtain an orange-red viscous shape substance;

[0034] (2) Under the condition of stirring, add 10ml pickling solution to make the orange-red viscous substance turn into a black liquid;

[0035] (3) Under the condition of stirring, add 137ml rinse solution, make pH=7, the black liquid gradually becomes the liquid containing orange-red particles and chlorine gas is generated, continue to stir for 30min; collect chlorine gas; chlorine gas can be prepared into polymer by conventional technology Ferric chloride products;

[0036] (4) Filter the liquid containing orange-red particles obtained in step (3) to obtain a colorless, clear and transparent neutral liquid...

Embodiment 3

[0039] The method for recycling the rinse solution in the production process of bleaching powder includes the following steps:

[0040] (1) At a temperature of 75-80°C and under stirring conditions, add 6.5ml of pickling solution to a container containing 80ml (88.56g) of rinse solution to make the pH = 5, stir evenly, and obtain orange-red viscous shape substance;

[0041] (2) Under the condition of stirring, add 20.5ml pickling solution to make the orange-red viscous substance turn into a black liquid;

[0042] (3) Under the condition of stirring, add 250ml rinse solution, make pH=7.5, the black liquid gradually becomes the liquid containing orange-red particles and chlorine gas is generated, continue to stir for 60min; collect chlorine gas; chlorine gas can be prepared into a polymer by conventional techniques Ferric chloride products;

[0043] (4) Filter the liquid containing orange-red particles obtained in step (3) to obtain a colorless, clear and transparent neutral l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com