Method for continuously preparing N-ethyloxyl oxalyl alanine ethyl ester

A technology of ethyl ethoxy oxalyl alanine and diethyl oxalate is applied in the field of continuous preparation of vitamin B6 intermediate - N-ethoxy oxalyl alanine ethyl ester, and can solve the problem of mild reaction conditions , the lack of high yield, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

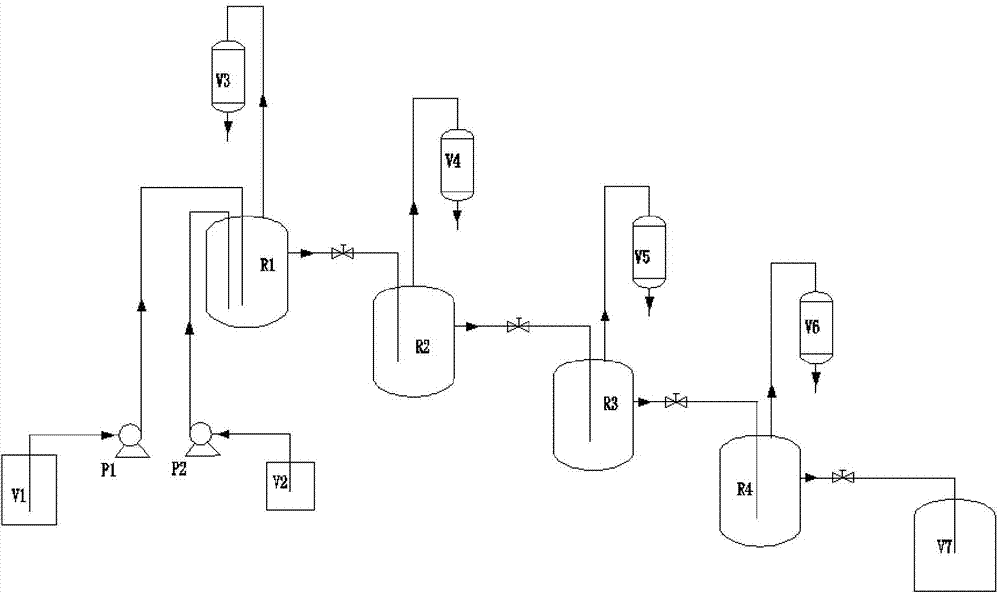

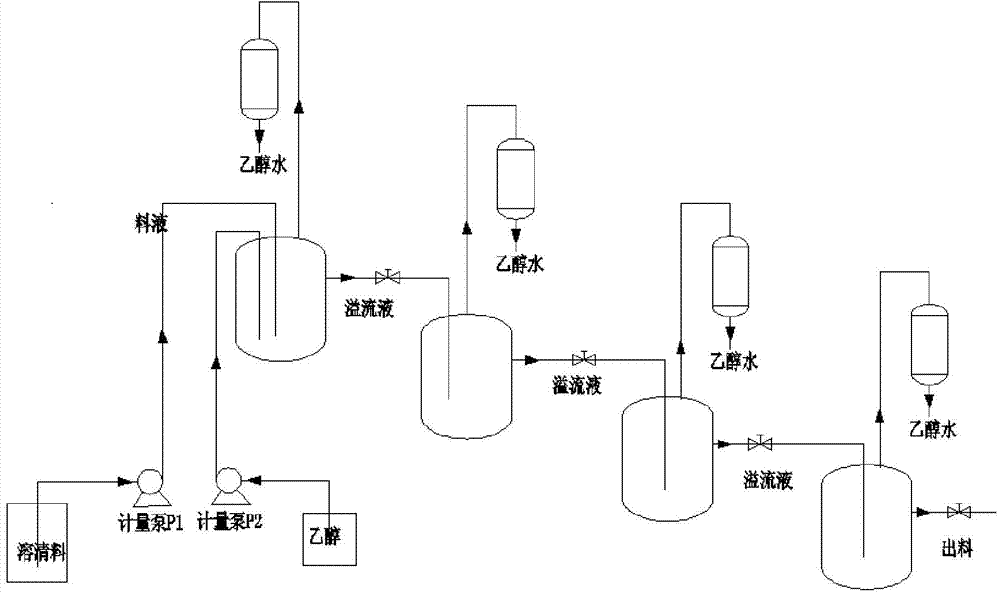

[0064] The preparation method of N-ethoxy oxalylalanine ethyl ester

[0065] A kind of method for preparing N-ethoxy oxalylalanine ethyl ester of the present invention is characterized in that, comprises the steps:

[0066] (1) providing a reaction feed liquid, containing alanine, oxalic acid, ethanol and diethyl oxalate in the described reaction feed liquid;

[0067] (2) adding the reaction feed liquid as a reaction system into the reaction device, and reacting in the presence of a water-carrying agent, so that the product water-carrying agent forms a water-water-carrying agent dispersion system; wherein, the water-carrying agent is ethanol;

[0068] (3) steaming out the water-water-carrying agent dispersion system, and removing excess diethyl oxalate to obtain the product N-ethoxy ethyl oxalylalanine.

[0069] The reaction feed solution can be obtained by any conventional method in the art, such as prepared by the following method: mixing alanine, oxalic acid, ethanol and ...

Embodiment approach 1

[0087] Embodiment 1: (3 kettles connected in series, residence time 20h)

[0088] In a 5L reaction flask equipped with mechanical stirring and a thermometer, add 600g of alanine, 933g of oxalic acid, 1551g of absolute ethanol, and 1181g of diethyl oxalate in sequence. To the first bottle in the overflow bottle of three 500ml in series, dissolve and clear the material, the total residence time is 20h, and use another metering pump to beat ethanol in the first overflow bottle with a speed of 2.89g / min simultaneously, The evaporation rate of the first bottle is 2.05g / min, the water content is about 9.5%, and the internal temperature is 90°C. After the bottle is full, it enters the next reaction bottle through overflow, and the evaporation rate of the second bottle is 1.03g / min. min, moisture 6%, internal temperature 94°C, the steaming rate of the third bottle is 0.34g / min, moisture 2%, internal temperature 98°C. And continuously receive the reacted reaction solution from the thi...

Embodiment approach 2

[0089] Embodiment 2 (3 kettles connected in series, residence time 25h)

[0090] In a 5L reaction flask equipped with mechanical stirring and a thermometer, add 600g of alanine, 933g of oxalic acid, 1551g of ethanol, and 1181g of diethyl oxalate in sequence. The first bottle in a 500ml series overflow bottle is used to dissolve and clear the material, and the total residence time is 25h. At the same time, another metering pump is used to beat ethanol in the first overflow bottle at a speed of 2.31g / min. The evaporation rate of the first bottle is 1.64g / min, the water content is about 10%, and the inner temperature is 90°C. After the bottle is full, it enters the next reaction bottle through overflow, and the evaporation rate of the second bottle is 0.82g / min. The water content is 6%, the inner temperature is 94°C, the steaming rate of the third bottle is 0.27g / min, the water content is 2%, and the inner temperature is about 98°C. And continuously receive the reacted reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com