Efficient extraction method for blueberry anthocyanin

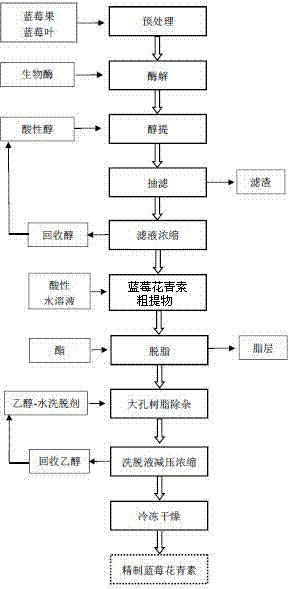

A blueberry anthocyanin and high-efficiency technology, which is applied in the direction of organic chemistry and the like, can solve the problems of strong seasonal harvesting and difficult storage of blueberry fruit, and achieves the effects of stable production process parameters, improved extraction rate and high application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Spray freshly picked blueberries with 0.02% cellulase at room temperature, and after 3.5 hours in the dark, add citric acid-60% ethanol at a ratio of 1:10 to liquid, continue to stir for 5 hours, and pump Filtration, the filtrate was rotated under reduced pressure to recover ethanol, and the crude extract of blueberry anthocyanins was obtained as a reddish-brown extract.

[0033] Dissolve the above-mentioned blueberry anthocyanin crude extract in an appropriate amount of citric acid solution with pH=3.0, extract with ethyl acetate three times, remove the fat layer, add the non-lipid layer to the DA201 macroporous resin column, and use 4 times the volume of ultrapure water, then eluted with 10% and 30% ethanol in turn, collected the 30% ethanol eluate, and recovered the ethanol by rotating under reduced pressure. The obtained product was freeze-dried to obtain purple-brown blueberry flowers Chin powder. Using 2% HCl-Methanol degradation method, the determination of anth...

Embodiment 2

[0035] The blueberries stored at -40°C and thawed overnight at 0°C were sprayed with 0.04% fruit juice enzyme at room temperature, and after 4 hours in the dark, citric acid-50% ethanol with pH=3.5 was added according to the ratio of solid to liquid 1:15 , continue to stir for 4 hours, filter with suction, spin the filtrate under reduced pressure to recover ethanol, and obtain the crude extract of blueberry anthocyanins, which is a purple-red extract.

[0036] Dissolve the above blueberry anthocyanin crude extract in an appropriate amount of hydrochloric acid solution with pH=1.0, extract with ethyl acetate for 3 times, remove the lipid layer, add the non-lipid layer to the AB-8 macroporous resin column, first use 3 times the volume of ultrapure water for elution, and then sequentially eluted with 10%, 25%, and 45% ethanol, collected 45% ethanol eluate, and recovered ethanol by rotating under reduced pressure. The obtained product was freeze-dried to obtain purple Brown bluebe...

Embodiment 3

[0038] Spray freshly picked blueberries with 0.02% cellulase-pectinase at room temperature. After 3.5 hours in the dark, add citric acid-70% ethanol with a pH=3.0 ratio of solid to liquid at a ratio of 1:8 and continue stirring. After 6 hours, suction filtration, the filtrate was rotated under reduced pressure to recover ethanol, and the crude extract of blueberry anthocyanins was obtained as a reddish-brown extract.

[0039] Dissolve the above blueberry anthocyanin crude extract in an appropriate amount of citric acid solution with pH=3.5, extract with ethyl acetate for 3 times, remove the lipid layer, add the non-lipid layer to D101 macroporous resin column, first use 4 Double the volume of ultrapure water for elution, then eluted with 10%, 25%, and 50% ethanol in sequence, collected 50% ethanol eluate, recovered ethanol by rotating under reduced pressure, and freeze-dried the obtained product to obtain purple-brown blueberry anthocyanin powder. Using 2% HCl-Methanol degrad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com