Single-component high temperature vulcanization conductive glue and preparation method thereof

A technology of conductive glue and high-temperature vulcanization, which is applied in the direction of conductive adhesives and adhesives, can solve problems such as inconvenient operation, complicated process, and poor adhesion, and achieve the effects of reducing assembly time, reducing raw materials, and excellent toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0019] Embodiment 1~3 is prepared according to the following steps:

[0020] (1) Conductive powder drying: Bake the conductive powder in a blast drying oven at 70°C for 2 hours to remove moisture;

[0021] (2) Conductive powder coating: at room temperature, put the conductive powder in step (1) into a high-speed mixer, slowly add the solution in which the coupling agent is dissolved, stir for 1-3 hours, and the filtered conductive powder The body is dried at 80-130°C for 0.5-2h, and it can be made into a conductive powder coated with a coupling agent. The amount of the coupling agent is 0.5-5% of the solvent, and the solution is toluene;

[0022] (3) Mixing: Addition-type liquid silicone rubber, catalyst with special structure, thixotropic agent, methyl hydrogen silicone oil, silicone oil containing special groups, conductive powder with coupling agent treatment prepared in step (2), at room temperature Add it to a double planetary mixer for 10-20 minutes and mix it, the stir...

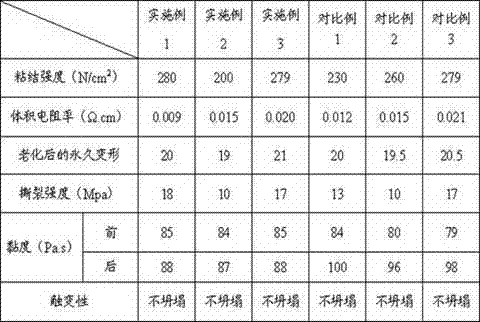

Embodiment 1-3

[0024] raw material Example 1 Example 2 Example 3 Comparative example 1 Comparative example 2 Comparative example 3 Addition type liquid silicone rubber (molecular weight 15~20w, commercially available) 80 70 90 80 70 90 Titanate coupling agent KR-TTS 0.01 A-174 (commercially available) 0.01 0.01 0.01 Aluminate coupling agent DL-411 0.01 0.01 Platinum catalyst with core-shell structure (commercially available) 0.0002 0.0002 0.0002 Ordinary platinum catalyst 0.0002 0.0002 0.0002 Hydroxy silicone oil 10 10 epoxy silicone oil 10 10 10 Ordinary silicone oil 10 Methyl hydrogen silicone oil 10 10 10 10 10 10 Fumed silicon (particle size: 30nm) 15 15 15 15 15 15 Silver clad copper 100 100 Nickel coated graphite 100 100 Sterling silver 100 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap