Construction method of tetracycline anoxia-tolerance strains

A construction method, tetracycline technology, applied in the field of construction of tetracycline-resistant low-oxygen strains, can solve the problems that restrict the improvement of antibiotic fermentation titer, the reduction of solubility and mass transfer efficiency, and the consumption of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. Preparation of competent cells of Escherichia coli ET12567

[0050] a) Inoculate 2uL of ET12567 glycerol frozen-preserved bacterial solution into LB medium, and culture overnight at 37°C and 180r / min on a shaking table. Transplanted in LB medium with 1% inoculum, cultured on a shaker at 37°C until the OD600 in the mid-log phase was 0.458.

[0051] b) 0-4°C, 4000r / min centrifuge to collect the bacteria, suspend the bacteria pellet in 2mL of pre-cooled 0.1 mol / L CaCl 2 solution, 1-5 ℃ ice bath for 20-30 min. Centrifuge at 0-4°C, 4000r / min for 10min, discard the supernatant, and collect the bacteria. Suspend the bacteria in 100uL pre-cooled 0.1 mol / L CaCl 2 solution, stored in a 4°C refrigerator for later use.

[0052] 2. Transform Escherichia coli competent cells

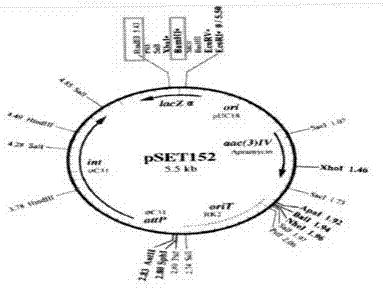

[0053] a) Take 100ul ET12567 competent cells into EP tubes, add 10uL expressable plasmid pSET152 of the Vitiligo hyaline hemoglobin gene, and bathe in ice (1-5°C) for 30min. Heat shock in a constant te...

Embodiment 2

[0065] 1. Preparation of competent cells of Escherichia coli ET12567

[0066] a) Inoculate 3uL of ET12567 glycerol frozen-preserved bacterial solution into LB medium, and culture overnight at 33°C and 200r / min on a shaking table. Transplanted in LB medium with 3% inoculum, cultured on a shaker at 35°C until the OD600 in the mid-log phase was 0.516.

[0067] b) Collect the bacteria by centrifugation at 3°C and 4000r / min, suspend the bacteria pellet in 2 mL of pre-cooled 0.1 mol / L CaCl 2 solution, ice-bathed for 30 min. Centrifuge at 3°C and 4000r / min for 5min, discard the supernatant, and collect the bacteria. Suspend the bacteria in 100uL pre-cooled 0.1 mol / L CaCl 2 solution, stored in a 4°C refrigerator for later use.

[0068] 2. Transform Escherichia coli competent cells

[0069] a) Take 60ul of ET12567 competent cells into an EP tube, add 8uL of expressable plasmid pSET152 of the Vitiligo hyaline hemoglobin gene, and bathe in ice at 1-5°C for 30-40min. Heat shock ...

Embodiment 3

[0082] 1. Preparation of competent cells of Escherichia coli ET12567

[0083] a) Inoculate 3uL of ET12567 glycerol frozen-preserved bacterial solution into LB medium, and culture overnight at 36°C and 200r / min on a shaking table. Transfer to LB medium with 3% inoculum amount, and culture on a shaker at 36°C until the OD600 in the mid-log phase is 0.433.

[0084] b) Collect the bacteria by centrifugation at 0-2°C and 4500r / min, suspend the bacteria pellet in 2 mL of pre-cooled 0.1 mol / L CaCl 2 solution in an ice bath for 30 min. Centrifuge at 0-2°C, 4500r / min for 7min, discard the supernatant, and collect the bacteria. Suspend the bacteria in 100uL pre-cooled 0.1 mol / L CaCl 2 solution, stored in a refrigerator at 4°C for later use.

[0085] 2. Transform Escherichia coli competent cells

[0086] a) Take 80ul of ET12567 competent cells into an EP tube, add 5uL of expressible plasmid pSET152 of Vibrella hyaline hemoglobin gene, and ice-bath for 20-30min. Heat shock in a cons...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com