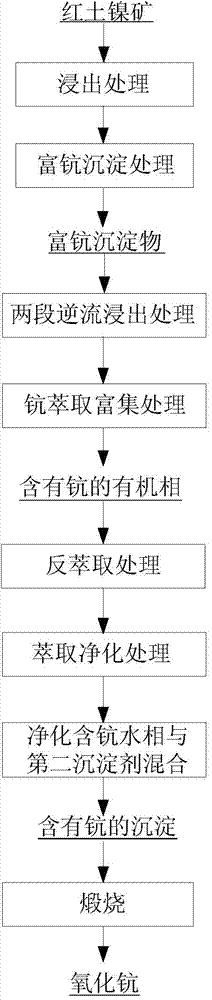

Method for extracting scandium from nickel laterite ores

A laterite nickel ore and extraction technology, applied in the field of metallurgy, can solve problems such as unstable effect of recovering scandium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] The main element content of a lateritic nickel ore is shown in Table 1

[0091] Table 1 Main element content of laterite nickel ore

[0092] unit

[0093] Among them, the content of iron is 13745.2 times that of scandium.

[0094] Using sulfuric acid at 250 °C and 0.5 MPa to perform pressure leaching treatment on laterite nickel ore, the main element contents of the obtained pressurized leachate are shown in Table 2.

[0095] Table 2 Contents of main elements in the pressurized leaching solution of lateritic nickel ore

[0096] unit

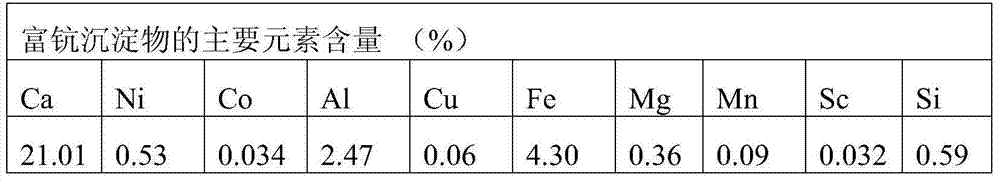

[0097] Add a mixture of 50% lime and 50% limestone to the pressurized leaching solution of lateritic nickel ore, adjust the pH of the solution to 4.5, and the temperature is 70°C, so that scandium in the pressurized leaching solution forms a scandium-rich precipitate, iron, aluminum and calcium and other elements Co-precipitation, its main element content is shown in Table 3. Among them, the content of iron is 134.4 ...

Embodiment 2

[0118] Add a mixture of 70% lime and 30% limestone to the pressurized leaching solution of laterite nickel ore, adjust the pH value of the pressurized leaching solution of laterite nickel ore to 6.0, and the temperature is 90 degrees Celsius, so that the scandium element in the pressurized leaching solution forms a scandium-rich precipitate, Its main element content is shown in Table 8. Among them, the content of iron is 82.2 times that of scandium. Scandium is co-precipitated with calcium, iron, aluminum, silicon and other elements. The content of scandium in the above-mentioned scandium-rich precipitate is 0.072%. Compared with laterite nickel ore, scandium is enriched by about 23 times, and it is separated from nickel and cobalt at the same time.

[0119] Table 8 Main element content of scandium-rich precipitate

[0120]

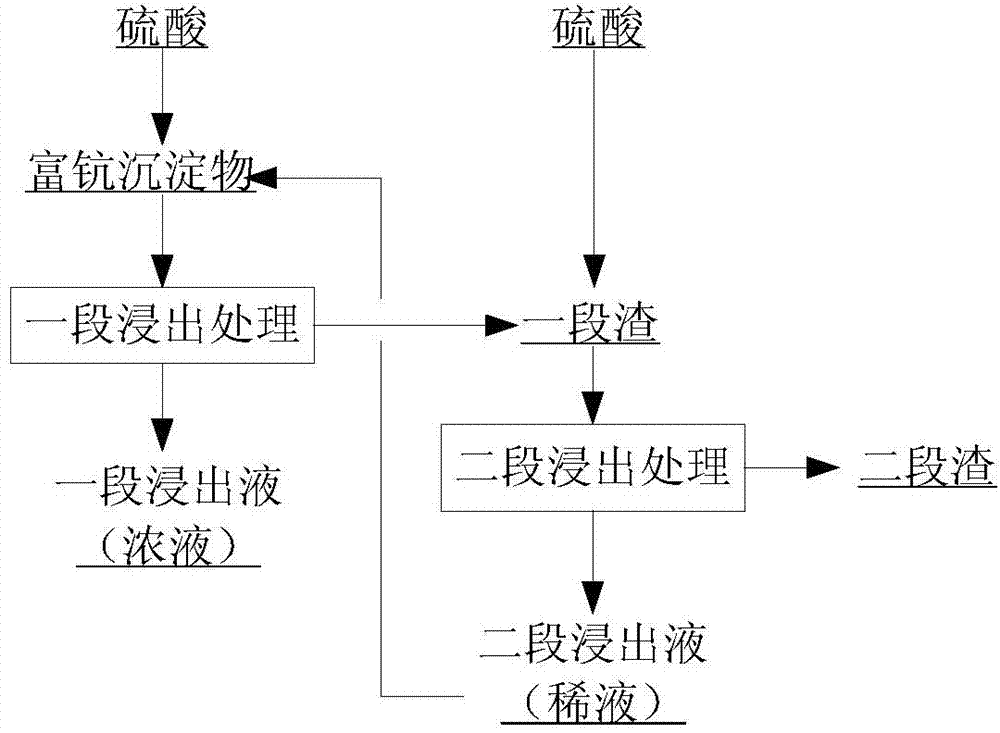

[0121] The above-mentioned scandium-rich precipitate is subjected to the first-stage leaching treatment of the two-stage countercurrent leaching trea...

Embodiment 3

[0128] With a section of leaching solution shown in Table 4, adjust the pH value to 3.0, according to the water phase: organic phase volume ratio=5:1, add 20% (v / v) carboxylic acid extractant CA12 (sec-octylphenoxyacetic acid) The kerosene solution is subjected to 8-stage scandium extraction and enrichment treatment, the extraction rate of scandium is 98.9%, the extraction rate of iron is 16.5%, the extraction rate of nickel and cobalt is close to 0, the extraction rate of manganese is 0.4%, and the extraction rate of magnesium 0.3%. Then the organic phase containing scandium is washed with 0.03mol / L sulfuric acid solution for 10 stages according to the water phase: organic phase volume ratio = 1:2, and most of the extracted impurities such as iron, nickel, cobalt, manganese, and magnesium are washed off, while scandium remains in the organic phase. Scandium is thus separated from impurities and enriched in the organic phase. The above-mentioned washed scandium-containing or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com