Film laminating process for loudspeaker mesh enclosure

A speaker and grille technology, which is applied in the field of film lamination process of speaker grille, can solve the problems of unable to meet the needs of sound transmission, poor dustproof effect, poor sound quality of speakers, etc., to shorten the production cycle and reduce equipment investment , Not easy to deform and wrinkle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiments.

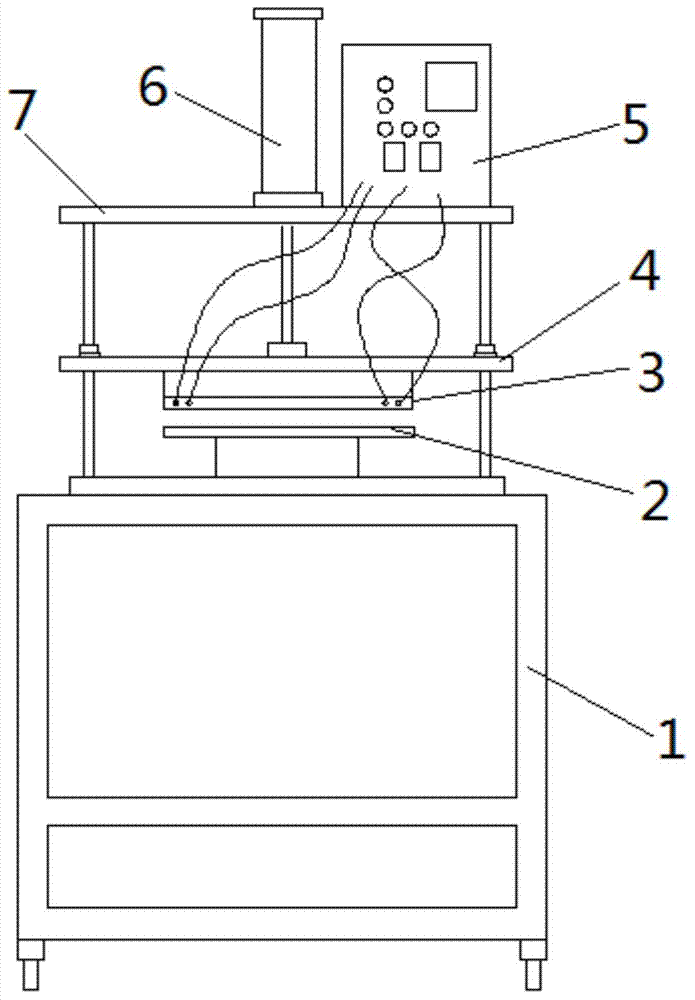

[0021] Such as Figure 1 to Figure 3 As shown, a film bonding process for the horn grille, including the following steps:

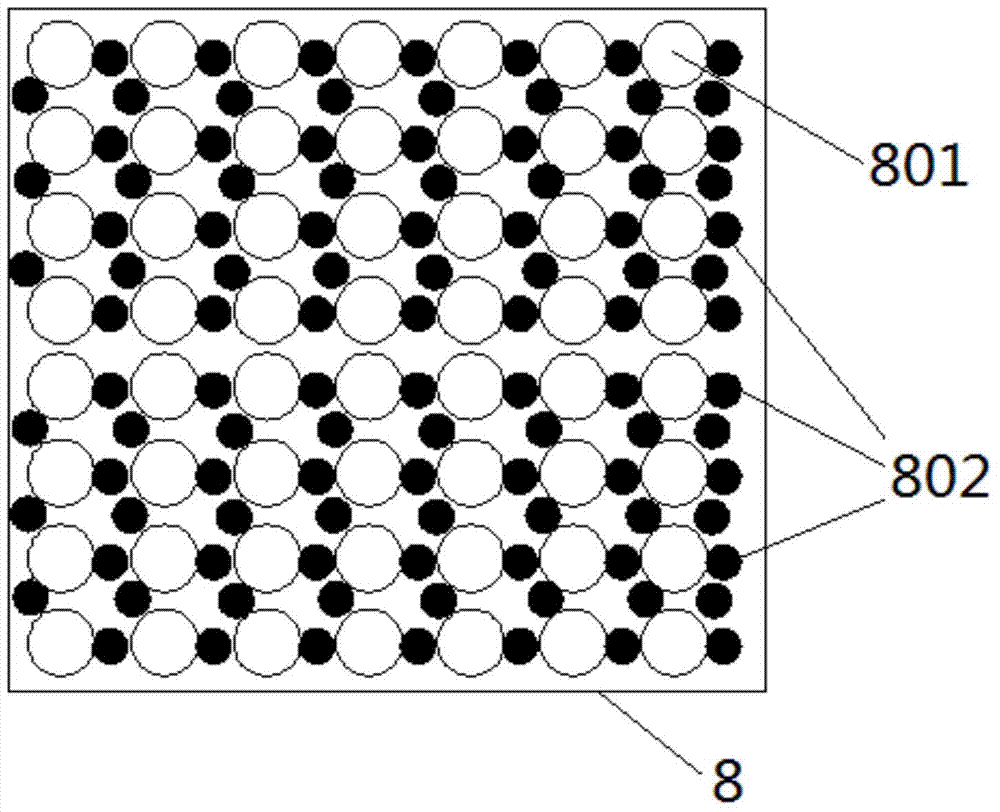

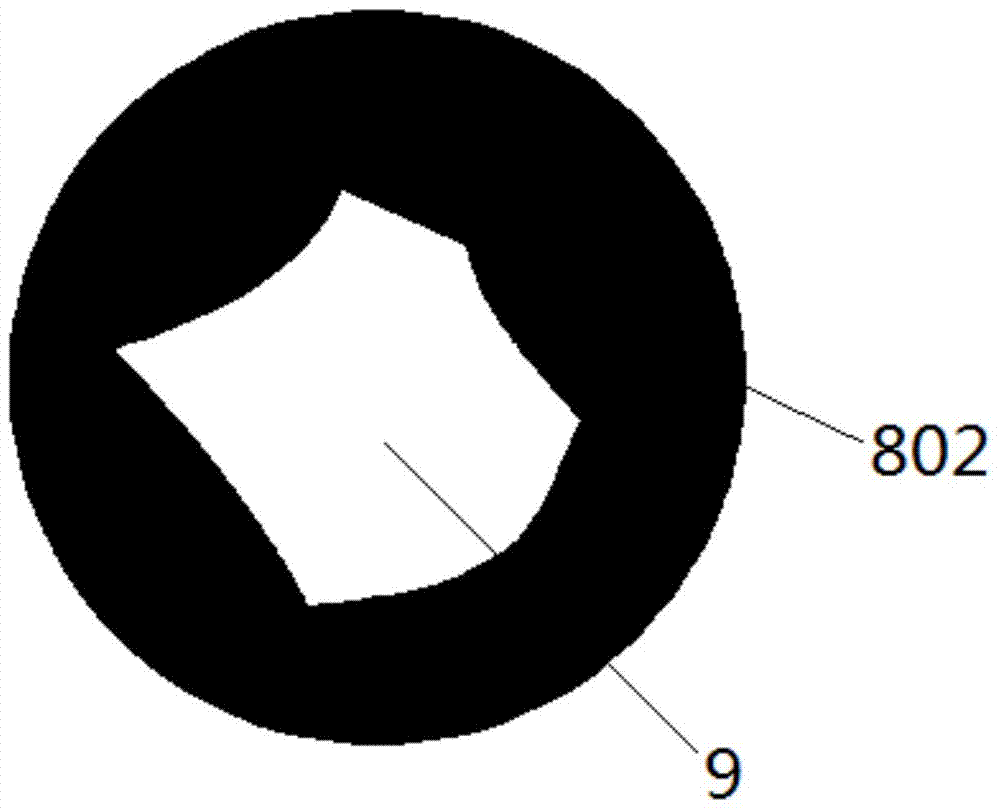

[0022] 1) Blanking: The polycarbonate sheet used to make the speaker grille is formed by injection molding technology, and the rolled surface has a mesh hot-melt film with protrusions 802. The mesh hot-melt film is covered with penetrating holes. Holes 801; the components of the hot melt film include 65 parts by weight of thermoplastic polyurethane, 14 parts by weight of nitrogen-phosphorus composite flame retardant, 34 parts by weight of melamine cyanurate, 16 parts by weight of triphenyl phosphate, 20 parts by weight of hydrogenated rosin, and 2 parts by weight of pentaerythritol ester. parts by weight;

[0023] 2) Cutting: According to the design requirements of the speaker product, the polycarbonate sheet in step 1 is cut into the appearance of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com